INTRODUCTION

The black soldier fly is an insect that looks like a black wasp but does not bite or sting. It is harmless to humans and animals.

Its larvae are rich in protein and fat, and very useful for

-Animal feed

-Waste management

-Oil and fertilizer production.

BSF larvae can eat many types of organic waste, like food waste (kitchen leftover), fruits and vegetables, manure, agriculture waste.

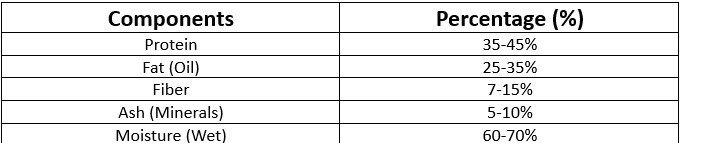

COMPOSITION

Black Soldier Fly (BSF) larvae are rich in nutrients, making them very useful in animal feed and other industries. They contain about 40–50% protein, which helps animals grow strong and healthy. They also have around 30–40% fat, mostly lauric acid, which is good for energy and has antimicrobial properties. In addition to protein and fat, BSF larvae contain minerals like calcium, phosphorus, magnesium, and potassium. They also have amino acids (like lysine and methionine) that are important for body growth. After the oil is removed, the leftover part (called defatted meal) still has high protein and can be used in feed. Overall, BSF larvae are a highly nutritious and natural product, ideal for feeding poultry, fish, pigs, and even pets.

BENIFITS OF BSF

1.Converts waste into useful products:

-BSF larvae eat organic waste like food scraps, fruit peels, and manure. This reduces garbage and turns it into protein, oil, fertilizer.

2.High protein for animal feed:

-BSF larvae contain 40-50% protein. Great for poultry, fish, pig, and pet feed a natural and cheap alternative to fishmeal.

3.Rich in oil (fat):

-Larvae have 30-40% oil (mainly lauric acid) used in animal feed, cosmetics, biodiesel production.

4.Produces organic fertilizer:

-After eating, the larvae leave dry waste called frass, rich in nutrients. Used as a natural fertilizer for plants and crops.

5.Fast growth and easy farming:

-Grows from egg to harvest in 10-14 days.

-Needs very little space and water, ideal for small-scale or large-scale farming.

6.Safe and harmless:

-BSF dose not bite or sting.

-Adult BSF does not spread disease very safe to raise near homes or farms.

7.Environment-Friendly:

-Helps in waste management.

-Reduces pollution, produce less greenhouse gases compared to other livestock farming.

8.Supports circular economy:

-Nothing is wasted

-Waste fed to larvae

-Larvae produce oil, protein and fertilizer and also helps zero waste system.

BSFL OIL EXTRACTION IMPORTANCE

Black Soldier Fly (BSF) larvae oil extraction is important because the larvae contain a high amount of natural fat (30–40%), which can be used in many useful ways. The oil is rich in lauric acid, a type of fat that has antibacterial and antifungal properties, making it useful in making animal feed, soap, and cosmetics. It also works as a source of energy in poultry and fish feed, helping animals grow better. BSF oil can also be used to produce biodiesel, which is an eco-friendly alternative to petrol and diesel. Extracting the oil also makes the remaining part of the larvae (called defatted meal) rich in protein and perfect for use in animal feed. So, oil extraction helps in using every part of the larvae wisely, reducing waste and adding value to BSF farm.

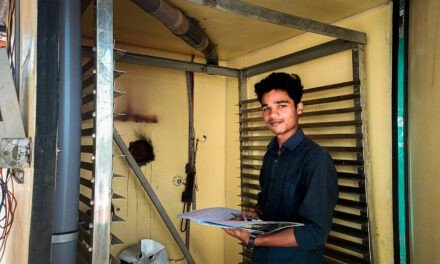

10/06/2025-11/06/2025

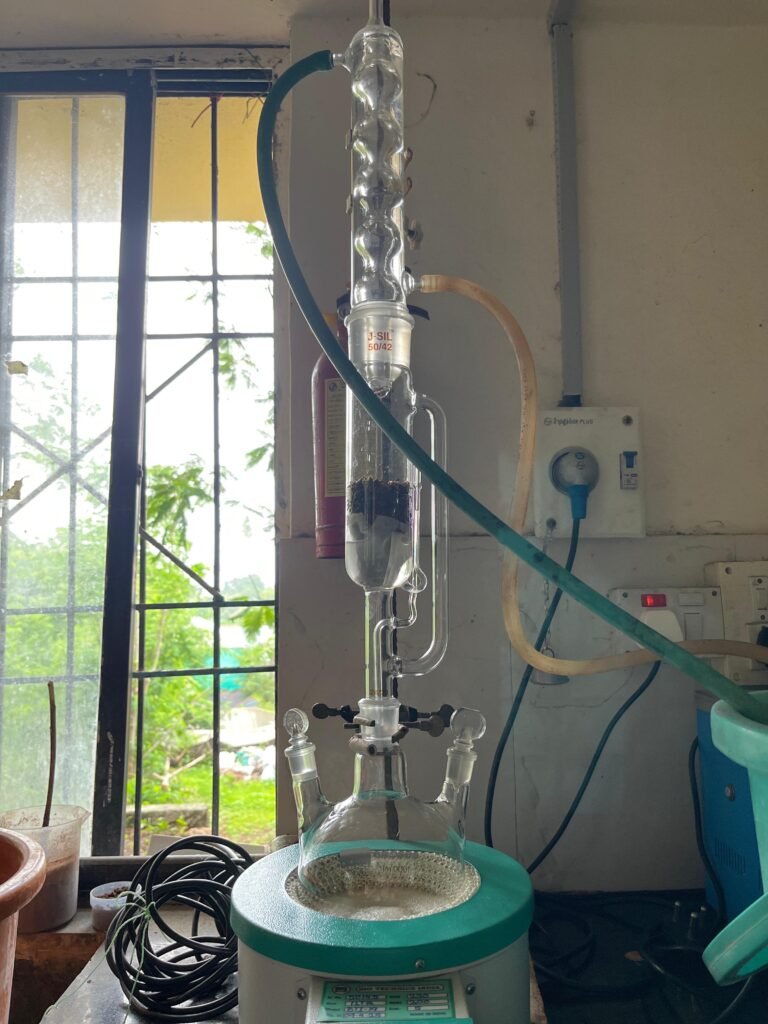

Dixit sir, Mahesh sir and me together to Soxhlet apparatus set up a system for extracting oil from black soldier fly larvae (BSFL). We carefully assemble the equipment needed for the process, making sure all the components were properly connected and safe to use. The setup involved drying the larvae, preparing the extraction unit, and using solvent to separate the oil. Each of us had specific roles during the setup-one focused on handling the larvae, another on monitoring the process. We successfully established a functional BSFL oil extraction setup for further experiments and production.

Equipment’s used in the experiment

1 Round bottom flask

2 Heating metal

3 Soxhlet extractor

4 Condenser

5 Rubber tubes

Setup of Soxhlet Apparatus

In this process, I am using whole dried Black Soldier Fly (BSF) larvae without any crushing or grinding, and 250 mL of ethanol is used as the solvent to extract the oil from them. Normally, grinding the larvae into a fine powder is known to increase the efficiency of oil extraction because it exposes more surface area for the solvent to act upon. However, even without grinding, this method still works and is especially useful when grinding equipment is not available, or when a simpler, quicker setup is preferred. The ethanol penetrates the outer surface of the larvae and gradually dissolves the oils contained within their bodies during the soaking and mild heating phase. Although the oil yield may be slightly lower compared to powdered larvae, this whole-larvae approach still provides a practical and accessible way to extract BSFL oil effectively on a small or experimental scale.

BSFL Oil Extraction Using Ethanol process:

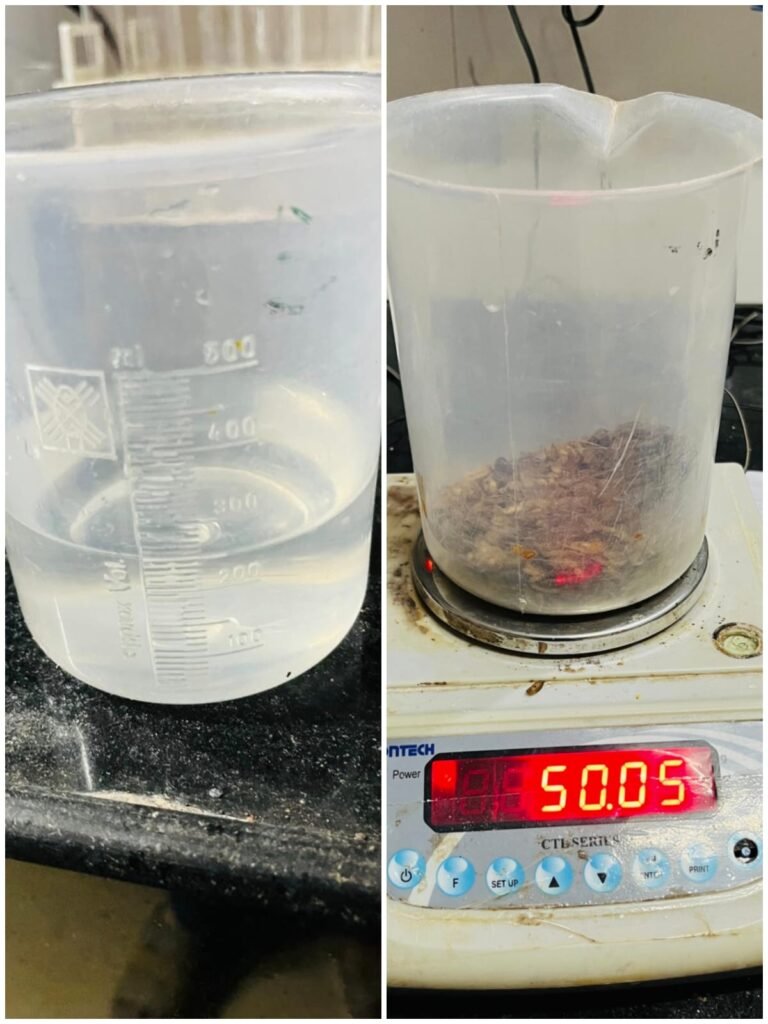

1 Loading the Sample:

• Whole dried BSF larvae 50gm are placed in the chamber inside the Soxhlet extractor. In another case, they are placed directly in the Soxhlet column without grinding.

2 Filling the Solvent:

• 250 mL of ethanol is added to the round-bottom flask connected to the Soxhlet apparatus.

250mL Ethanol and 50gm of larvae

3 Heating:

• The heating mantle below the flask heats the ethanol gently until it starts to boil (~78°C). The ethanol evaporates and moves upward as vapor.

4 Condensation:

• The ethanol vapor reaches the condenser at the top, where it is cooled by circulating water (through the rubber pipes), and turns back into liquid.

5 Extraction Cycle:

• The condensed ethanol drips into the Soxhlet chamber, soaking the larvae completely.

• As ethanol fills the chamber, it dissolves oils and fats from the BSF larvae.

• Once the chamber fills up to a certain level, the siphon tube automatically drains the ethanol-oil solution back into the round-bottom flask.

6 Repeat Cycles:

• The process of evaporation → condensation → soaking → siphoning repeats automatically for several hours (commonly 6–8 hours).

• With each cycle, more oil is extracted from the larvae into the ethanol.

Oil Extraction Process

13/06/2025

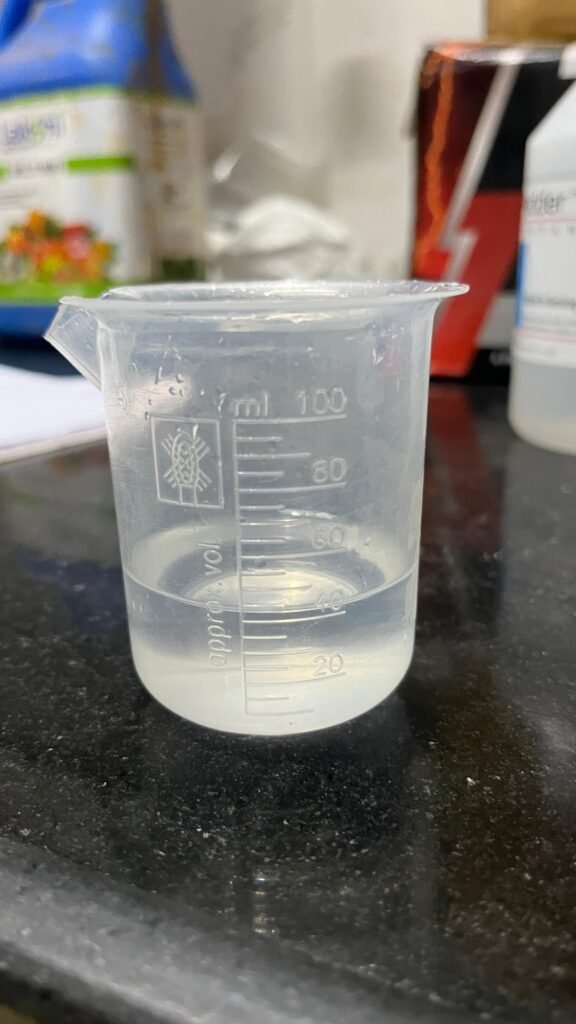

7 Solvent recovery:

• After enough extraction cycles, the ethanol in the flask now contains dissolved BSF oil.

• This ethanol-oil mixture is then separated using distillation:

• Ethanol is evaporated and collected for reuse.

• Remaining material is pure BSFL oil.

Ethanol and Oil Separation Process

During the separation of the solvent and oil, the temperatures of both the liquid and vapor phases were measured. The temperature of the liquid was recorded at 77°C, while the temperature of the vapor was slightly higher at 87°C.

14/06/2025-15/06/2025

After completing the oil extraction using ethanol, the entire apparatus was thoroughly cleaned to ensure that no residue or solvent traces remained, which could interfere with the next experiment. Once the cleaning was done and the glassware was completely dried, preparations were made to conduct a new oil extraction using hexane as the solvent. The Soxhlet apparatus was carefully assembled again, making sure all joints were properly sealed and the system was set up correctly for efficient and safe operation. This step was essential to maintain the accuracy and reliability of the results in the subsequent hexane-based extraction process.

BSFL Oil Extraction Using Hexanes process:

1 Loading the Sample:

• Whole dried BSF larvae 50gm are placed in the chamber inside the Soxhlet extractor. In your case, they are placed directly in the Soxhlet column without grinding.

2 Filling the Solvent:

• 250 mL of hexanes is added to the round-bottom flask connected to the Soxhlet apparatus.

250mL Hexane and 50gm Larvae

3 Heating:

• The heating mantle below the flask heats the hexanes gently until it starts to boil (~60-70°C). The hexanes evaporates and moves upward as vapor.

4 Condensation:

• The hexanes vapor reaches the condenser at the top, where it is cooled by circulating water (through the rubber pipes), and turns back into liquid.

5 Extraction Cycle:

• The condensed hexanes drips into the Soxhlet chamber, soaking the larvae completely.

• As hexanes fills the chamber, it dissolves oils and fats from the BSF larvae.

• Once the chamber fills up to a certain level, the siphon tube automatically drains the hexanes-oil solution back into the round-bottom flask.

6 Repeat Cycles:

• The process of evaporation → condensation → soaking → siphoning repeats automatically for several hours (commonly 6–8 hours).

• With each cycle, more oil is extracted from the larvae into the hexanes.

Oil Extraction Process

7 Solvent recovery:

• After enough extraction cycles, the hexanes in the flask now contains dissolved BSF oil.

• This ethanol-oil mixture is then separated using distillation:

• Hexanes is evaporated and collected for reuse.

• Remaining material is pure BSFL oil.

Hexanes and Oil Separation Process

During the separation of the solvent and oil, the temperatures of both the liquid and vapor phases were measured. The temperature of the liquid was recorded at 65°C, while the temperature of the vapor was slightly higher at 66°C.

16/06/2025

BSFL Oil Extraction Using Hexanes and Iso Propyl Alcohol process:

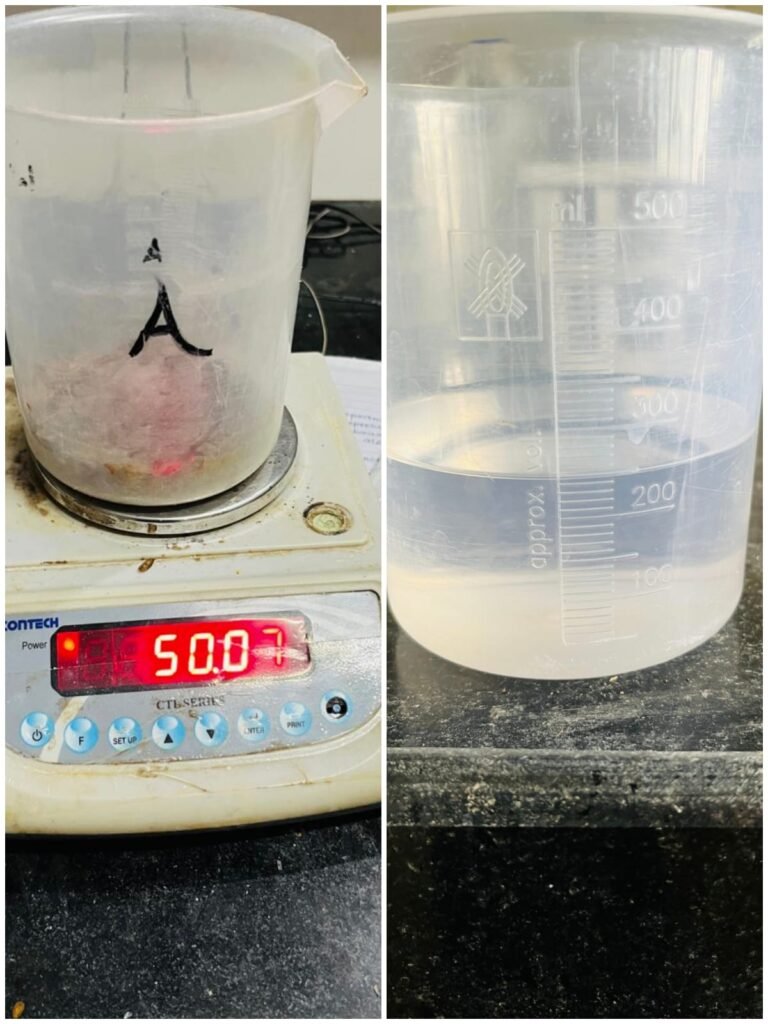

1 Loading the sample:

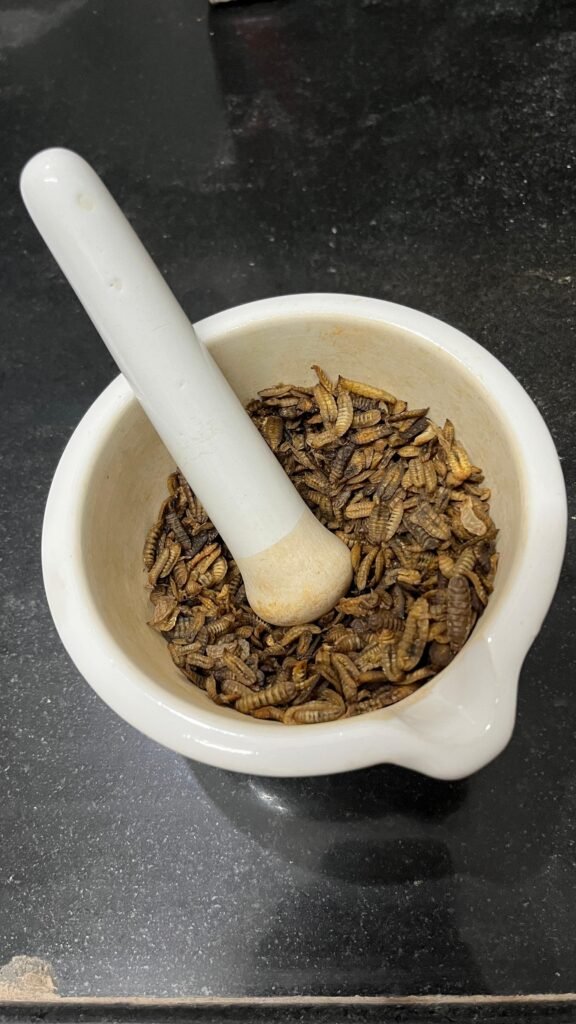

-50 grams of Black Soldier Fly (BSF) larvae are ground into a coarse mash using a grinder. Grinding increases the surface area and improves the efficiency of oil extraction.

-The mashed larvae are then loaded into the Soxhlet extractor chamber.

Before Mash of Larvae

After Mash of Larvae

2 Solvent Mixture Preparation:

-A mixture of 40 mL of isopropyl alcohol (IPA) and 210 mL of hexane is prepared, making a total volume of 250 mL solvent.

-This solvent mixture is poured into the round-bottom flask attached below the Soxhlet extractor

40mL of IPA

210mL of Hexane

50gm of Larvae

3 Heating:

-The flask is gently heated using a heating mantle.

-As the mixture heats up (around 60–70°C), the solvents begin to boil and vaporize.

-Since hexane has a lower boiling point (~69°C), it vaporizes first and carries some IPA vapors with it.

4 Condensation:

-The solvent vapors travel up into the reflux condenser at the top of the Soxhlet setup.

-Cold water is circulated through rubber tubes connected to the condenser, cooling the vapors.

-The vapors condense into liquid form and drip back down into the Soxhlet chamber.

5 Extraction Cycle:

-The condensed hexane + IPA mixture begins to soak the mashed larvae inside the Soxhlet chamber.

-As the solvent contacts the sample, it dissolves the oils, fats, and some bioactive compounds from the larvae.

-Once the chamber reaches a certain fill level, the built-in siphon tube automatically drains the solvent (now carrying dissolved oil) back into the round-bottom flask.

-This ensures a continuous circulation of fresh solvent over the sample.

6 Repeating the Cycle:

-The steps of evaporation → condensation → soaking → siphoning repeat automatically for 6 to 8 hours.

-With each cycle, more oil is extracted from the larvae into the solvent mixture.

-Over time, the concentration of BSF oil in the solvent in the flask increases.

Oil Extraction Process

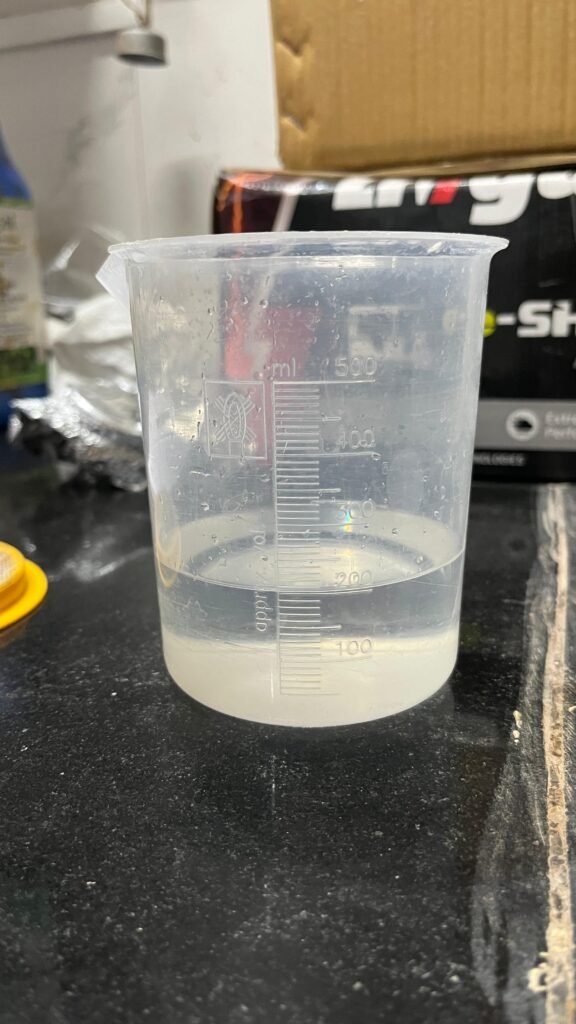

7 Solvent Recovery:

-After sufficient extraction, the round-bottom flask contains a hexane-IPA-oil mixture.

-This mixture is then subjected to distillation to separate the solvents from the oil.

-Hexane and IPA are evaporated off and can be collected for reuse.

-The remaining residue in the flask is the pure BSF larvae oil, ready for further processing or analysis.

Oil and Solvent Separation Process

During the separation of the solvent and oil, the temperatures of both the liquid and vapor phases were measured. The temperature of the liquid was recorded at 75°C, while the temperature of the vapor was slightly higher at 78°C.

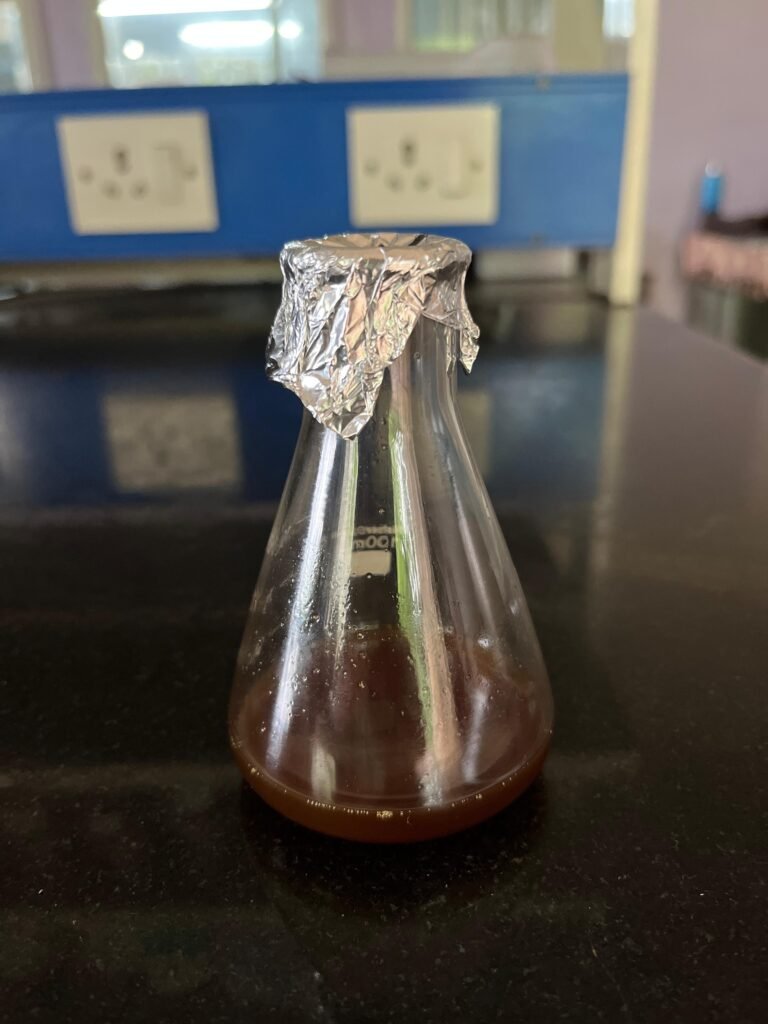

Final Product

Conclusion:

In this experiment, 50 grams of mashed Black Soldier Fly (BSF) larvae were used to extract oil using a mixture of two solvents: 40 mL of isopropyl alcohol (IPA) and 210 mL of hexane. First, IPA was added to help break the cell walls of the larvae and release the oil. Then, hexane was used because it is effective at dissolving and extracting oil. Mashing the larvae increased the surface area, which made it easier for the solvent mixture to reach and extract the oil. In the end, about 19.62 mL of oil was collected. This shows that BSF larvae are a good source of oil and that the combined use of IPA and hexane is an effective method for oil extraction.