DATE: 12 june 2023

The day start in a vigyan ashram lot of projects vitalities and real time experience with a different kind of technology’s aspects introduce by Dr.Arun Dixit sir.

TOPICS

- heat pump

- alternator

- sand batteries

Tasks

- Incinerator

- Pawar dryer

- Cad modelling of dryers

Detail about topic

1} HEAT PUMP

Basically, heat pump is an device design to transfer the heat . Conceptually its an arrangement of heat transferring mechanism for transferring heat from low tempreture to high tempreture.

2} ALTERNATOR

Its an new system demanded in vigyan ashram to shift solar power generation in direct utilizations in place of transferring it to M.S.C.B ; The way alternator is needed is an proxy where all there direct contact of electricity load should bear or utilize at good efficiency without losses.

3} SAND BATTERIES

s There are various types of batteries use in this era but in place of using lithium and liquids batteries the concept sand batteries are introduce the storage of heat without using electric mean to maintain the temperature even in cold environment or where the warmness is needed.

Details about Tasks

1} Inseminator

Its and pad disposal /pad burning machine designed . this burner helps to burn the pads without spreading much pollution.

The tasks is to modify the positions and install new mechanism for more efficient result .

2} Pawar dryer

This dryer is been order by resident its function is to dry the 50kg vegetable in one set of drying .

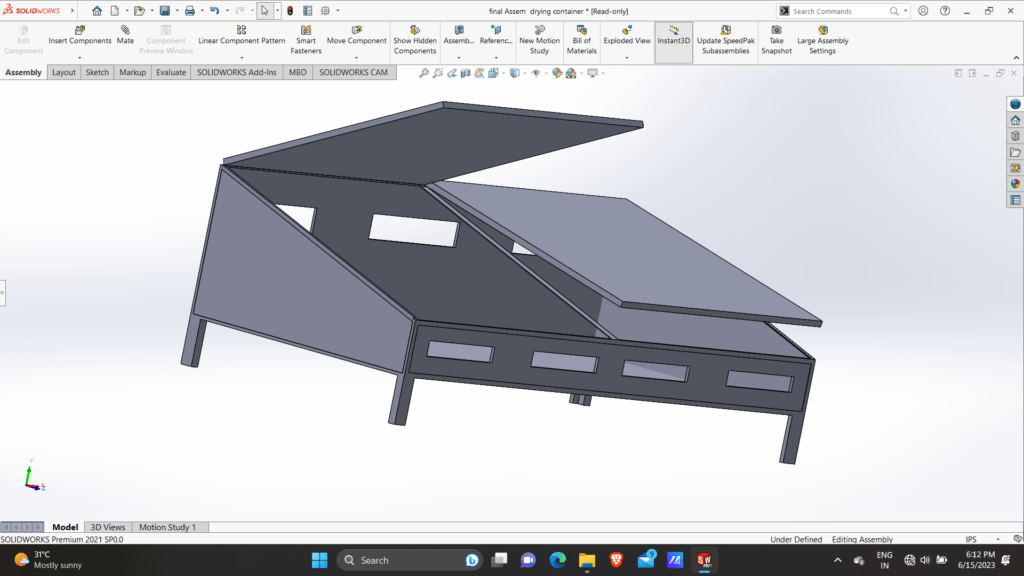

3} Cad modelling

This is an assignment provided by prasad patil sir to design a all drying models present in vigyan ashram like: dome dryer ,inclined container ,etc .

heat pump drying in vigyan ashram

DATE: 13 june 2023

CAD MODELLING OF FLAT DRYER

flow

- Observation

- Parts

- Dimensions

- Part drawings

- Assembly submission .

This is a type of dryer made of metal frame support body with plywood and the upper casing with poly carbonate material. This device use to dry up the vegetables and fruits by using sun rays and air supply for evaporation of water.

DATE: 14 june 2023

Ananlize the heat pump dryer in vigyan ashram

What’s the problem?

HEAT PUMP DRYING SYSTEM USE TO REMOVE MOISTURE FROM VEGETABLE

Accordingly the issue is this dryer don’t circulate the heat in cycle for drying up and required heater for tempering the container .

MODIFICATION / DEMAND

1} heat use should be same and cyclic .

2} no external supplies for heating .

3} evaporator and chambers to store heat .

4} new mechanism .

DATE:15 june 2023

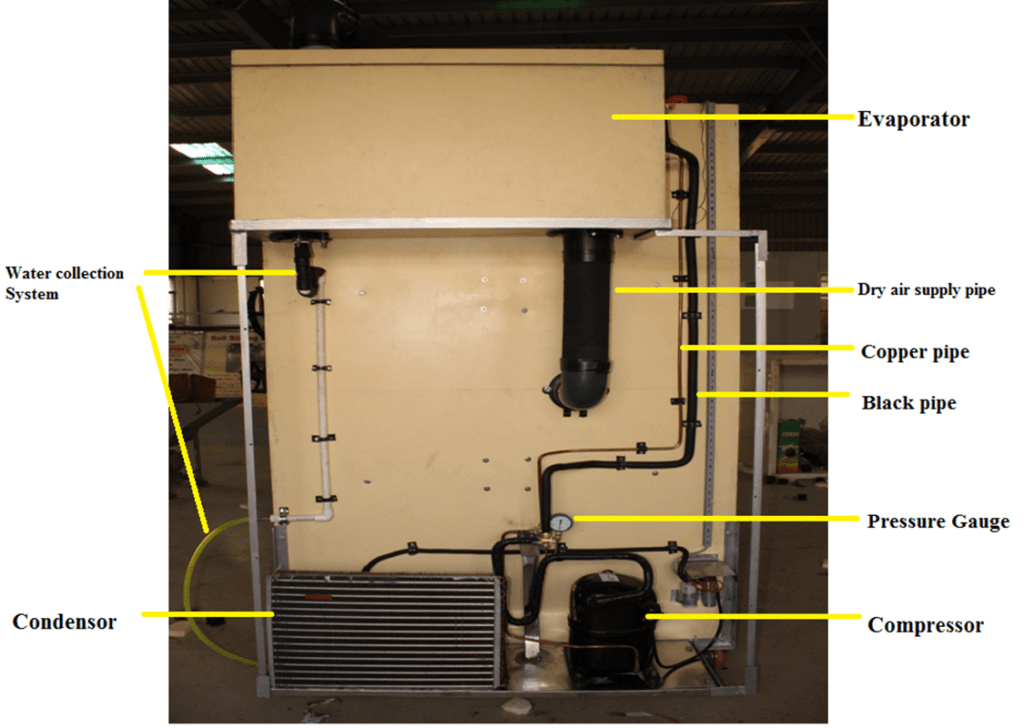

COMPONENTS LIST OF HEAT PUMP DRYING SYSTEM AND ITS WORKING :

MAIN COMPONENT

1] RADIATOR : Radiators are heat exchangers used to transfer thermal energy from one medium to another for the purpose of cooling and heating.

2] COMPRESSOR:A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

3] SUCTION PIPE /RELEASING PIPE: This are the pipes generally use to transfer the air from radiator to chamber or suck the air from chamber to outside .

4] CONTROLLERS : is a hardware device or a software program that manages or directs the flow of data between two entities.

5] CHAMBER : It’s a container which use to store the materials or a space where although mechanism will be used. its made up of insulating material’s ore simply its a mechanical body.

DATE:16 June 2023

discussion with senior come to visit about modification.

Shubham and Rishabh sir are the ex member of vigyan asharm who started the concept of dryer its a glad meet to them and discus all the concepts and contents about heat pump present in vigyan ashram .We concluded the circuit requirement of our upcoming smart heat pump dryer.

DATE:17 June 2023

The whole we are on travelling for loading and unloading of E-Rikshaw.

DATE:18 June 2023

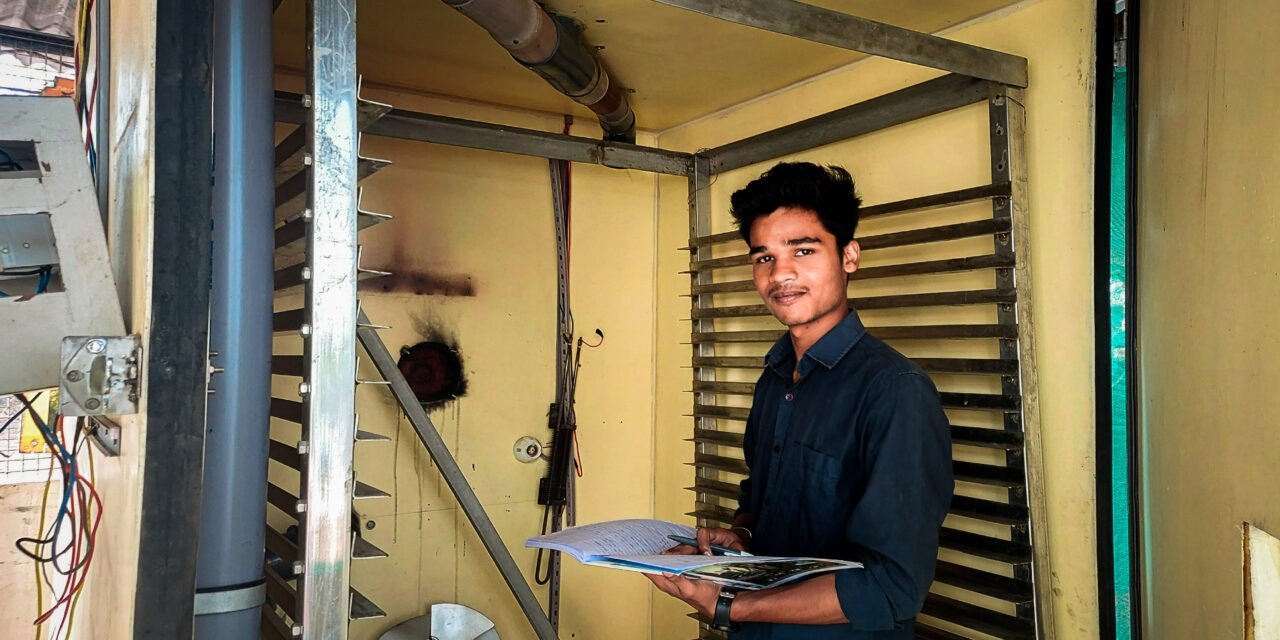

Disassembly of heat pump for deep analyzation of it.

We had disassembly all the parts of heat pump for proper view and deep understanding of present dryer

and then detail discussion about each part with senior facuilty.

DATE:19 June 2023

Bill of material.{task}

i have submitted my assignment given by prasad patil sir of cad model of flat bed dryer with its all specification and define properties’ call as bill of material.

DATE:20 June 2023

Discussion about the efficiency’s of various dryers .

>CALCULATIOS

>ALL BASIC INFORMATION AND IT NEED

>EFFECTIVENESS AND REQUIRMENTS.

DATE:21 June 2023

Cad modelling of water wheel electrification

This was is appeal from a guy name MICKEL ECHART came from Germany to complete hi project of water wheel electrification with coordination of vigyan ashram so as a mechanical i worked as a model making .

DATE:22 June 2023

Detail discussion on heat pump’

We had Compared the present condition of dryer and the required changes:

- chamber : to use the heat of cooling system of compressor

- heat exchanger

- no need of external heater

- new connections.

DATE:23 June 2023

Searching for the material use for the component need in heat pump.

This day we just list out the materials we can use in new part that is going to install in heat pump .

configurations :

1] materials :expanded polystyrene , polystyrene foam ,fiber glass ,etc.

2] Heat capacity of that material {should bear heat up to 100 degree}

3] Availability

4] Costing/Effectiveness {comparisons}

DATE:24 June 2023

Building a box for heating chamber .

This is an first step toward heat pump new part which is to be installed.

There is an good idea to reuse the heat of compressor to heat the cold air and pass from radiator by converting the cooling system of compress into a heater of cold air by just providing a chamber to heat sink and removing the fan use for cooling .For the we have build a box where all this happen in a enclose container .

DATE:26 June 2023

we have taken temperature readings from a present heat pump dryer to get assumptions in designing the heat exchanger.

From this readings we get the inlet temperature for a required heat exchanger is about 10 degree Celsius and outlet needed is 30-35 degree Celsius accordingly we need to design heat exchanger

DATE:27 June 2023

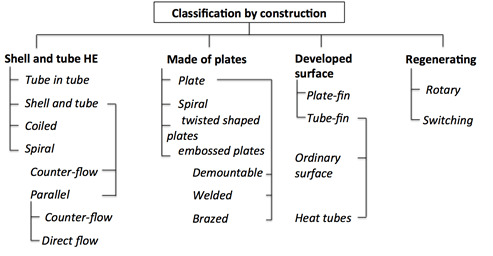

Detail study of heat exchanger for selection of suitable type which will acceptable for all requirements in dryer.

DATE:28 June 2023

Door lamination training and FRP insulation training.

this training is for IBT batch of teachers we join this training since we need to build one chamber of FRP insulation for the heat sink segment which will provide a heat to heat the air from normal to more after coming from heat exchaner.

DATE:29 June-10july 2023

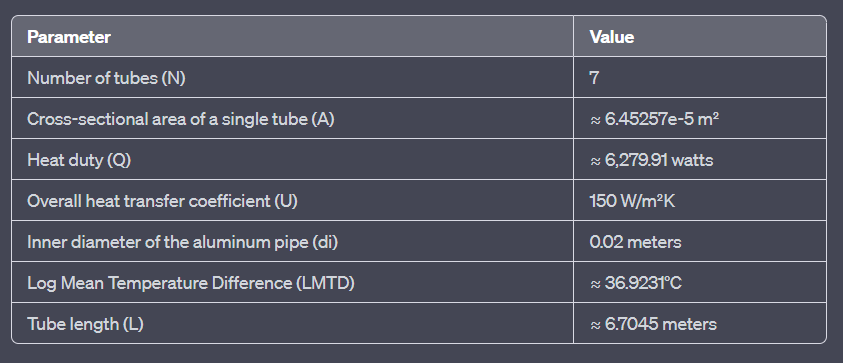

From date 29 June to 10 July all days are invested in calculations and methodology for getting design of shell tube heat exchanger .

CALCULATION PARTS :

- DESIGN AND TYPE OF HEAT EXCHANGER

- COMPATIBILITY

- DURABILITY

- HEAT DUTY

- MASS FLOW RATE

- DENSITIES

- VELOCITIES

- MATERIALS

- LENGTH OF TUBE AND SHELL

- DIAMETER OF TUBE

- THICKNESS OF TUBE AND SHELL

- OVERALL HEAT TRANSFER COEFFICIENT

- LMTD

- TEMPERATURE DIFFERENCES

- SURFACE AREAS

- THERMAL CONDUCTIVITY

- CONVECTIVE HEAT TRANSFER COFFICIENTS

FOR THIS CALCULATIONS WE USE BASIC ASSUMPTIONS AND GENRAL VALUES USE IN INDUSTRIES FOR REFRENCE.

- FRICTION FACTOR

- HT MODULE 1.PDF

- MODDY CHART

- REYNOLDS NUMBER

- RELETIVE HUMIDITY CONCEPT

- RELEATIVE TOUGHNESS’

- CORELEATION OF HEAT TRANSFER

- LITERATURES

- psychometric calculator

CALCULATIONS:

The formula to calculate heat duty (Q) is:

Q = ṁ * Cp * ΔT

Using the calculated values, we can find the mass flow rate:

ṁ = ρ * V * A {area is calculated by assuming air is coming through pipe of 12cm dia and enters in pipe of ineer dia 5cm and outer dia 5.5 cm with

. velocity 15m/s}

ṁ ≈ 1.225 kg/m³ * 15 m/s * 0.001963 m²

ṁ ≈ 0.036 kg/s or approximately 36 g/s

Therefore, the mass flow rate of air through the tube is approximately ṁ ≈ 0.036 kg/s or 36 g/s.

Specific heat capacity of air (Cp) = 1005 J/kg·K (at approximately 25°C)

Substituting the values:

Q = 0.036 kg/s * 1005 J/kg·K * 20°C { temperature difference we need to covert a cold air of 5-10 deg to 30-35 deg }

Q ≈ 721.8 W or 721.8 j/s

ΔT = T_hot_water_inlet – T_cold_air_outlet

ΔT = 55 -30 { here we know we need to covert a cold air of 5-10 deg to 30-35 deg by hot water of 55 deg in shell which is heated by solar heater}

ΔT = 25 degree Celsius

Given Parameters:

Heat Duty (Q): 721.8 W/k

Overall Heat Transfer Coefficient (U): 150 W/m² K Overall Heat Transfer Coefficient (U): 150 W/m² K we take direct value from by considering moderate factors

. this value is use typically in industrial applications.

Temperature Difference (ΔT): 25°C

Tube Inside Diameter: 5 cm (0.05 m)

Tube Outside Diameter: 5.5 cm (0.055 m) {we assume the tube dimensions by own no reason }

Shell Length: 1 m

Calculate the effective heat transfer area (A):

The effective heat transfer area represents the surface area available for heat transfer. It can be determined using the formula:

A = Q / (U * ΔT)

Given:

Q = 721.8 W

U = 150 W/m² K

ΔT = 25 °C

A = 721.8 W / (150 W/m² K * 25 °C)

= 1.93 m²

Calculate the total inside surface area of the tubes (A_tube):

The total inside surface area of the tubes can be determined using the tube diameter and the shell length. Assuming a triangular pitch arrangement, we can use the following formula:

A_tube = π * (do – di) * L * Nt

Given:

Tube inside diameter (di) = 0.05 m

Tube outside diameter (do) = 0.055 m

Shell length (L) = 1 m

Let’s assume a typical number of tubes (Nt) for a 1-meter shell length, such as 100 tubes:

A_tube = π * (0.055 – 0.05) * 1 * 100

= 0.07854 m²

Calculate the tube length (L):

The tube length can be estimated by dividing the effective heat transfer area (A) by the total inside surface area of the tubes (A_tube):

L = A / A_tube

L = 1.93 m² / 0.07854 m²

≈ 24.59 meters

DATE:10-16 july2023

Poster and ppt prepration for exibition {dryers}

DATE:17 july2023

This brainstorming session was held where all DIC members is present to discuss the heat pump.

The topic was HEAT EXCHANGER

We started with calculating values in which we analyzed the required value to design the heat pump.

1} heat duty

2} overall heat transfer rate

3} temperature difference

The heat duty is calculated with the help of mass flow rate depending on the velocity of the air and the temperature difference is known according to the output we required. The main problem was in calculating the overall heat transfer rate because to calculate the overall heat transfer rate we need the materials of shell and tube.

So, we decided.

Shell: Mild Steel

Pipe: Aluminum

Based on the flow of air {laminar/turbulent} there are ranges of convective heat transfer coefficient so here we get stuck to designing the heat exchanger.

Since assuming all the values it’s not the appropriate way to go for performance so the conclusion of the meeting was, we first we will try on a prototype of a 2m aluminum pipe then we will go for the original length according to requirements.

DATE:18 july2023

On this day there is a distribution of extra project activities

So, I got asked for 2 more projects.

1} Dome dryer

2}automatic gate system for Vigyan Ashram

First, I analyze the dome dryer, what is it and what work is pending and make a note of it. I got a partner for this project Rahul Bhanje.

DATE: 20 july2023

We started work on the dome dryer. The dome dryer works on sunlight heating which was used to remove the moisture from the product. The dome dryer is covered with a black sheet, there were gaps on the land side so to cover that we made hooks on each 1 meter on the sheet and tied all that with broad thread.

After doing this we result in only 60 % there are gaps so for that we decided to dig the dome 2-3 inch for this we dig the hole at every joint down the dome and at the outer circumference with small hole linings and this resulted in good results the dome dryer get totally pack only left was the door side.

DATE:21 july2023

Dome dryer air circulation:

We build the duct system inside the top of the dome dryer for the circulation of air with flexible pipe and fan.

And assemble the door cover with a black sheet and fix the nuts. And the plywood of the door was painted black Japanese.

DATE:2 Aug2023

1st trail for heat exchanger .

We used aluminium pipe of one meter coverd with plastic pipe.

We had made setup such as the aluminium pipe is connected with the cold air coming from heat pump inlet with the help of reducer which reduce the dia of 12cm to 2cm aluminium pipe since we use only single pipe for getting some assumption and the hollow plastic pipe is filled with hot water of 50 degree tempreture .

The results:

The inlet air is of 10 degree which now passing through setup now its tempreture is 30 degree and one but htere is a reduction in velocity due to reducer. After we close the heat pump we find that now tempreture inside the heat pump is normal as atmosphere means its not cold as before.

DATE:3 Aug 2023

Discussion on the resulted readings in which we decide the flow should not be steady . In this experiment we arrange the setup in which air is flowing but hot water is maintain at steady state and acoordingkt we had take a readings of outlet and inlet system.So not in we change the setup and build new one by installing water pump for water circulation which is of 18 WATT and its work.

DATE:4 Aug2023

As pr new setup we take a readings and we got new readings and so more good results just one we miss ,that we dont maintain water tempreture constantly since its an manual process and in next experiment we did it.

DATE:5 Aug2023

Now by doing all changes we take final readings on 3rd trail. For cross checking of calculation made by me before a month we use present values of the data from this experiment on 1 m aluminium pipe. Not excatly but ita approximately same as the calculated values before . Now question is overall heat transfer cofficient considerstion for exact values of shell tube type heat exchanger.

CALCULATIONS:

CONCLUSION:

In conclusion, The calculations I previously conducted, based on certain assumptions, closely align with the experimental readings obtained from a 1-meter aluminum pipe immersed in hot water. This implies that a 1-meter aluminum pipe is an effective heat transfer medium when exposed to high temperatures.

To extend this concept further, by utilizing seven one-meter aluminum pipes encased within a hot water shell maintained at 60 degrees Celsius, it becomes feasible to convert air starting at 15 degrees Celsius to a more elevated temperature of 35 degrees Celsius. This first stage of the heat exchanger design demonstrates the potential of enhancing air temperature.

Subsequently, by channeling this 35-degree air through a dedicated chamber designed for the compressor’s heat sink, the air’s temperature can be elevated further to a range of 70-80 degrees Celsius. This preheated air is then directed into the cabinet, optimizing the efficiency of the drying process beyond that achievable with regular compressed air.

The entire system is optimizing the drying capacity of the air. This is achieved by initially reducing the air’s temperature, causing it to release moisture. Subsequently, the air’s temperature is elevated again, effectively lowering its humidity level. This process enhances the overall efficiency of the drying operation, surpassing the capabilities of conventional compressed air.

This how the heat pump will be work .

Concluding Note