All you need to know about Laminar Air Flow!

Laminar Air Flow (LAF) chambers are indispensable tools in microbiology laboratories, providing a controlled environment to protect cultures from contamination. Ensuring the proper maintenance of these chambers is crucial for the accuracy and reliability of research. This blog post will delve into the importance of LAF maintenance, the key components that require regular attention, and essential maintenance procedures to keep your LAF chamber operating at peak performance. By understanding and implementing these guidelines, you can contribute to a safe and productive laboratory environment.

Filtration

- Sedimentation: Larger particles settle due to gravity.

- Electrostatic Attraction: Charged particles are attracted to oppositely charged filter fibers.

- Interception: Particles larger than the filter pores are physically trapped.

- Inertial Impaction: Larger particles have more momentum and are unable to change direction as quickly as smaller particles, impacting the filter fibers.

- Diffusion: Brownian motion causes smaller particles to collide with filter fibers.

Key Components:

A Laminar Air Flow (LAF) chamber is composed of several essential components that work together to provide a clean, contaminant-free environment. These components include:

- Housing: The main structure of the chamber, typically made of stainless steel or other durable materials.

- HEPA Filter: A High-Efficiency Particulate Air filter that removes 99.97% of airborne particles, including bacteria, fungi, and dust.

- Prefilter: The Prefilter is a Polyethylene Matrix Air filter which removes 90% of airborne particles.

- Blower: A fan that draws air through the HEPA filter and pushes it into the chamber at a high velocity.

- Work Surface: A flat, sterile surface where laboratory procedures are conducted.

- UV Light: A ultraviolet light source that can be used to disinfect the chamber between uses.

- Controls: A panel of buttons or switches that allow the operator to control the chamber’s functions, such as airflow rate and UV light activation.

September 23, 2024

Problems in the LAF Chamber

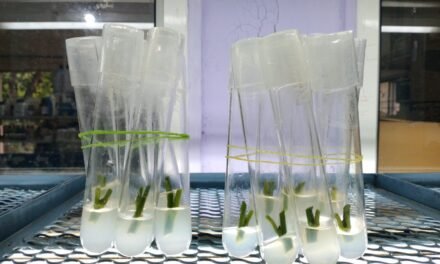

To ensure optimal performance and prevent contamination in your LAF chamber, it’s essential to conduct regular checkups. There has been various cases of Biological Contamination in the LAF Chamber. The LAF Chamber in the Microbiology Lab in Vigyan Ashram has been regularly failing in delivering filtered air in the chamber resulting in Contamination.

Here’s a list of routine steps that we followed for checking the LAF Chamber:

- Switch “OFF” the UV light.

- Clean the equipment with clean lint-free cloth duster and spray 70% IPA solution to LAF unit and entire Area of LAF room.

- Switch “ON” the “AIR” and Visible Light switch situated on the control panel on the right-hand side of the instrument.

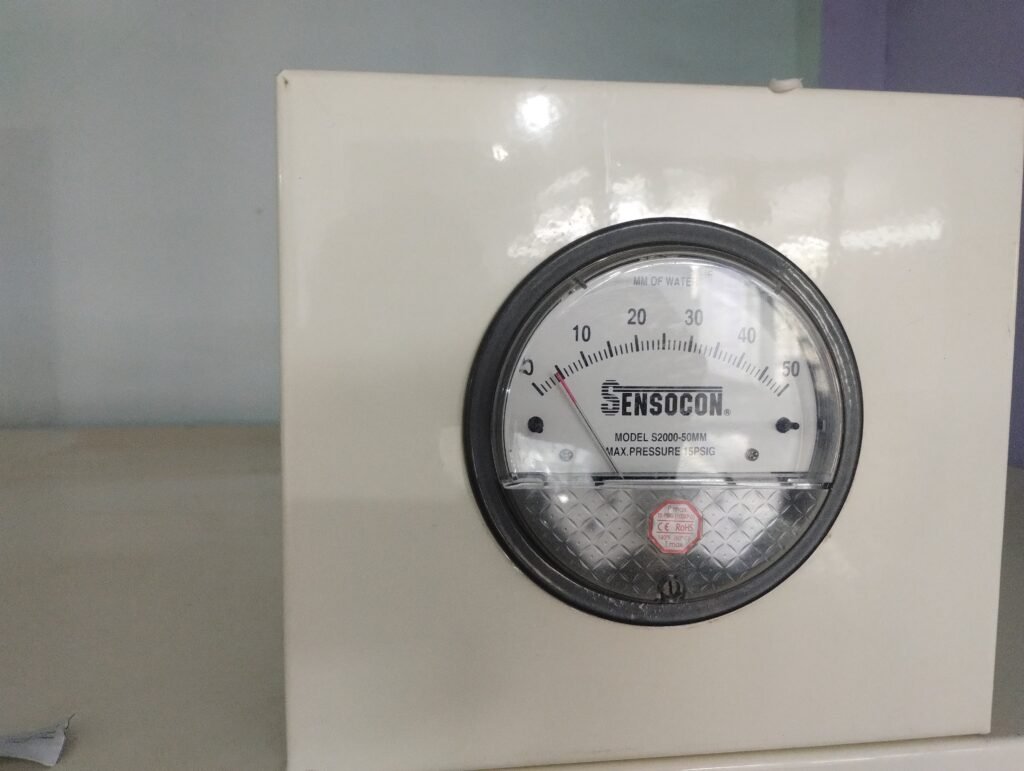

- Now check the LAF Manometer pressure, it should be within 10 – 20 mm of Water Gauge.

- Check the log record for burning hour of UV light, it should not exceed more than 2000 hours. UV tube should be replaced after a specified burning period.

- Start the gas burner with the help of gas lighter and carry out the routine works.

- After completion of work, switch OFF the Airflow and gas burner.

- Clean any remaining water or waste liquid material spilled on the laminar airflow platform properly with a dry cloth.

- Clean properly the working chamber from the ceiling, followed by side glass and then the platform of the chamber with sterile 70% IPA.

- Spray sterile 70% IPA and switch OFF the Visible light and then Switch ON the UV light till to start the next operation.

- If the LAF is used for Aseptic filtration, clean the receiver pipe tank with hot WFI.

- Open the outlet of Solution Collection Tank and collect the solution in a plastic crate. Close the valve and transfer the crate for solution disposal.

Read more at: https://www.pharmaguideline.com/2009/01/sop-for-operation-of-laminar-air-flow.html

We realized that the Filters may not be working properly as the pressure gauge showed reading lower than the rated LAF Manometer Pressure. Hence we proceeded to visually inspect the Filters.

September 29, 2024

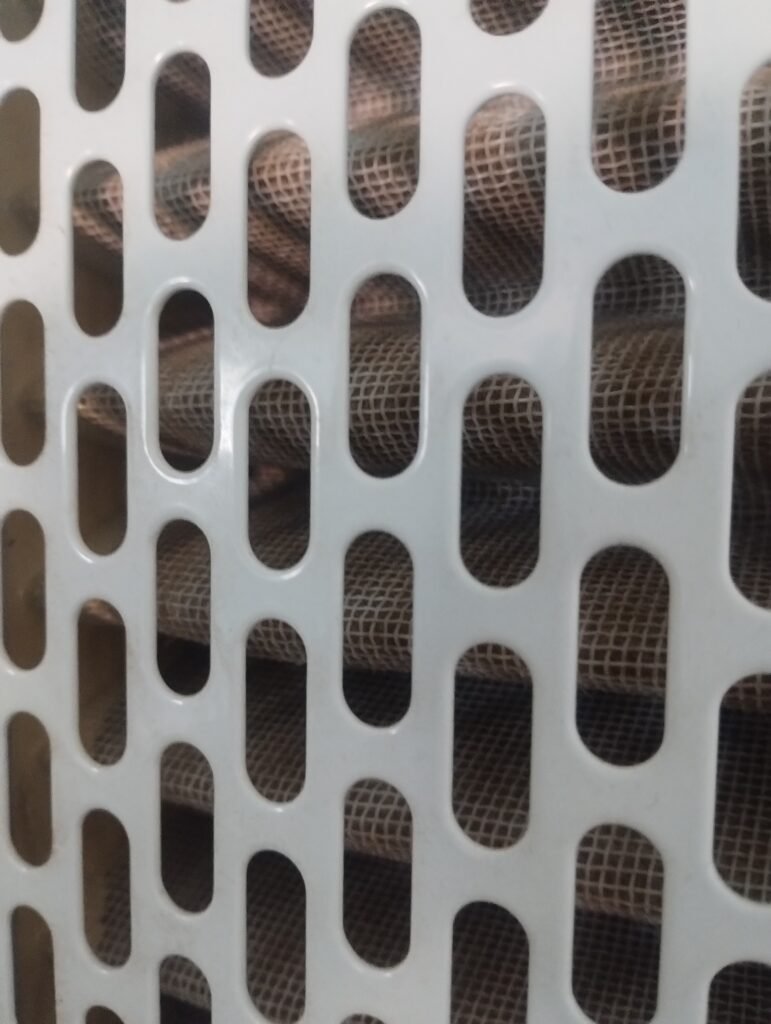

Cleaning of Prefilters

The prefilters were then cleaned as per the Standard Operating Procedure (SOP) for maintenance of Prefilters:

- First of all, Switch ‘OFF’ the mains of LAF, loosen the bolts properly and take out the Prefilter slowly, without any jerks from the LAF.

- Then Shift the filter to wash area outside microbiology analysis room where cleaning is to be done. Ensure the left out opening of the Prefilter on the LAF unit shall covered with butter paper in order to prevent dust as well as the outside air moving inside the LAF unit.

- First de-dust the filter properly with the help of dry, oil free compressed air. The compressed air shall be forced properly to prefilter of LAF otherwise it will damage the filter.

- After dedusting, clean the prefilter properly 2-3 times with Purified water. Allow all the water to drain completely after water cleaning.

- Then dry the prefilter after proper draining in a clean dry environment free from the dust; otherwise the chances of contamination in the sterile environment may arise or it may decrease the efficiency of the prefilter. Do not dry the prefilter in an open environment.

- Spray 70% IPA solution filtered through 0.45 m filter and mop SS attachment of the prefilter properly before transferring inside the microbiology analysis area.

- Affix the cleaned prefilter properly in appropriate place by removing the butter paper cover and tighten the bolts properly.