Study of Permanent Hardness in Fogger Systems

Introduction:

In polyhouses and greenhouses, fogger systems are mainly used to maintain humidity by spraying fine mist. However, after continuous use, foggers often get blocked because of salt deposits when hard water is used.

In this study, I focused on understanding permanent hardness by preparing hard water artificially. For this, I added calcium sulfate (CaSO₄) to RO water to create conditions similar to those found in real field situations where borewell water is used.

What is Permanent Hardness?

Permanent hardness occurs due to the presence of calcium and magnesium salts that cannot be removed by boiling. These salts include:

- Calcium sulfate (CaSO₄) – low solubility

- Magnesium sulfate (MgSO₄) – very high solubility

- Calcium chloride (CaCl₂) – high solubility

- Magnesium chloride (MgCl₂) – very high solubility

Why Study Permanent Hardness?

- To Simulate Real Field Water Conditions

Farmers generally use borewell or untreated water which contains calcium and magnesium salts. These salts accumulate in fogger nozzles and form hard layers over time. - To Understand the Cause of Fogger Choking

When water evaporates, salts such as calcium sulfate remain and form solid white deposits. These block the fogger nozzles and reduce misting efficiency and cooling performance. - To Develop Cleaning Methods

By intentionally clogging foggers using hard water, we can check which cleaning chemical or process works best and how often foggers need maintenance.

Fogger Clogging Experiment Using CaSO₄ (Calcium Sulfate)

Foggers mainly get choked due to salts like calcium, magnesium, sulfates, chlorides, and bicarbonates present in water. In this experiment, we tried to observe the choking behavior of foggers in practical conditions by using calcium sulfate solution, which represents permanent hardness.

Experimental Setup:

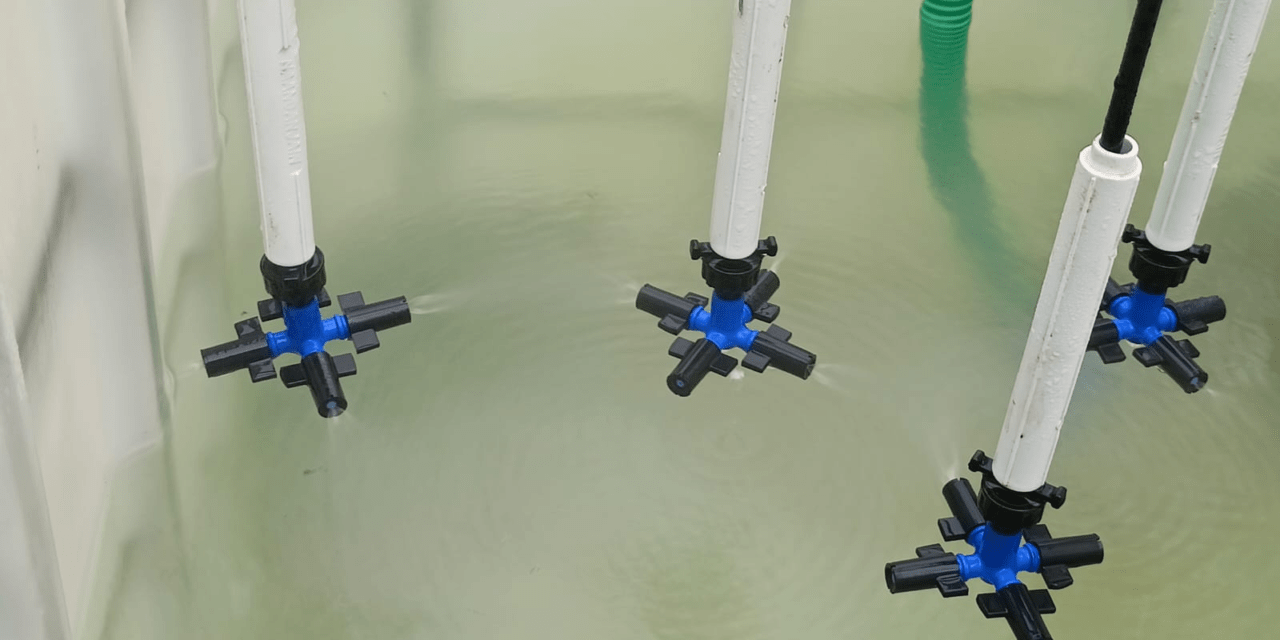

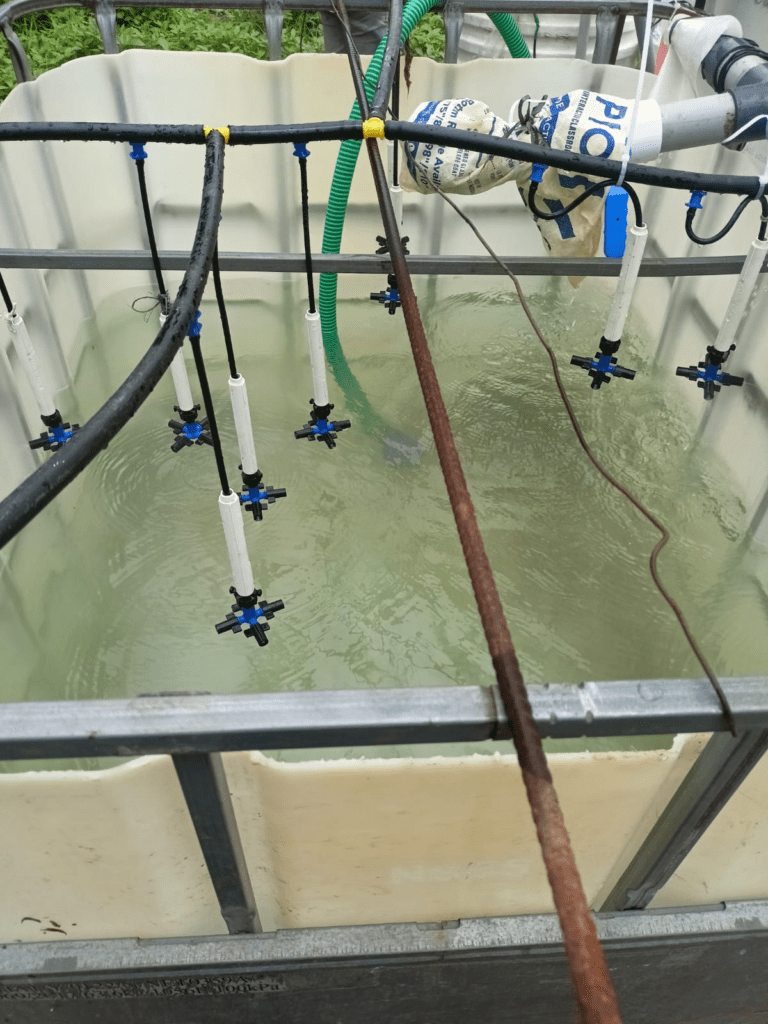

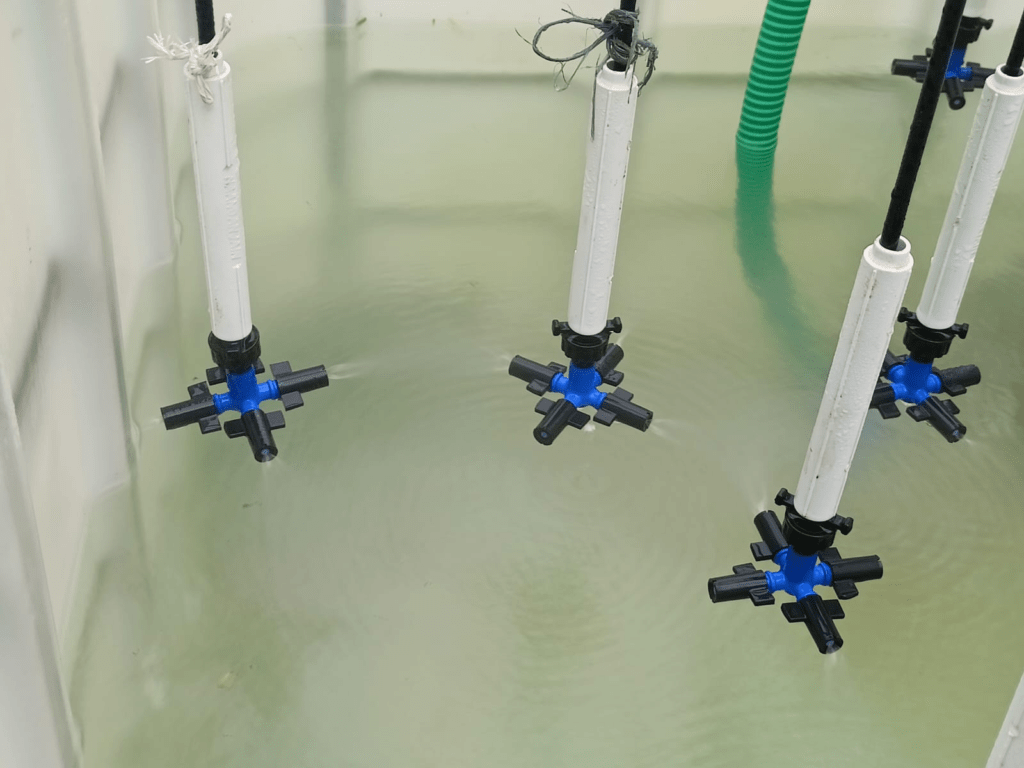

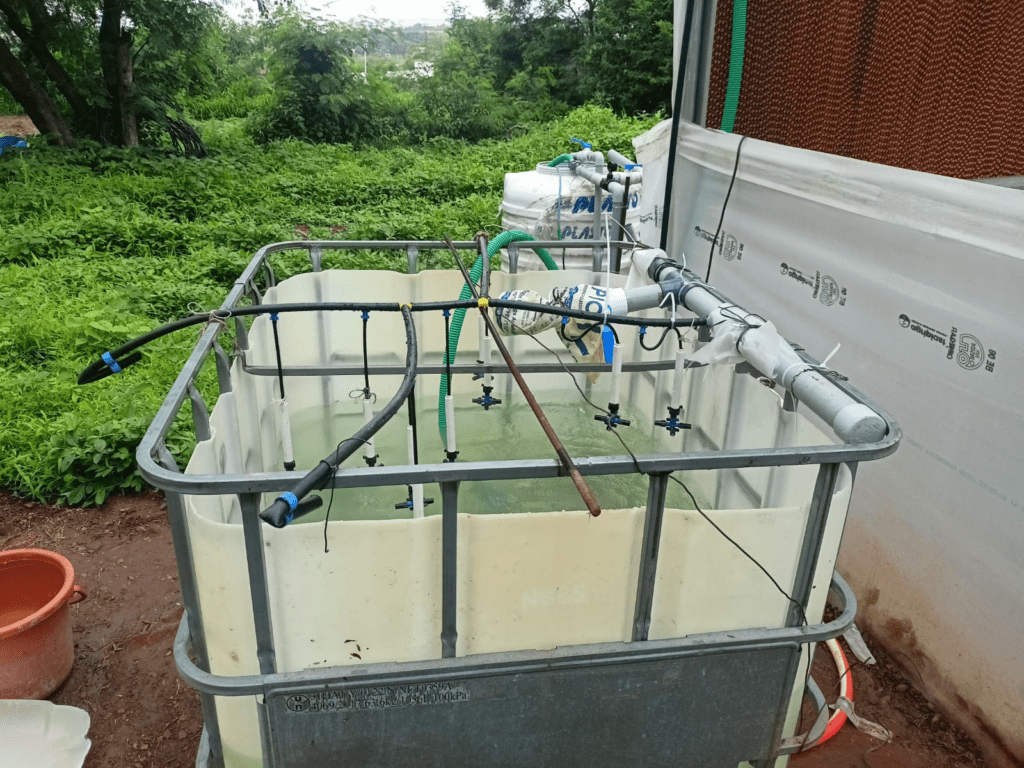

- A 1000-liter IBC tank was used for the experiment.

- The top of the tank was cut open and filled with around 700 liters of RO water.

- 1.47 kg of calcium sulfate (CaSO₄) was added to the tank water.

- A cross-shaped lateral pipe setup was made and fixed at the top of the tank to mount foggers.

- 9 foggers were installed on this lateral setup.

- A 1 HP motor was connected to pump the solution through PVC pipes to the foggers.

After setting up the system, the foggers were operated continuously to observe clogging.

Result:

The foggers were run for around 8 hours daily. After 2–3 days, the mist output started reducing gradually. By the eighth day, most foggers were completely blocked, and white salt deposits were clearly visible. This confirmed that calcium sulfate caused choking due to permanent hardness.

08/10/2025 to 10/10/2025

Turbo Fogger Setup in Polyhouse

Introduction:

Currently, in the polyhouse, we are working on testing and comparing three different types of foggers to determine which one performs best for our trials. The main purpose of this setup is to study the efficiency of each fogger in terms of mist quality and uniformity inside the polyhouse.

Setup Preparation:

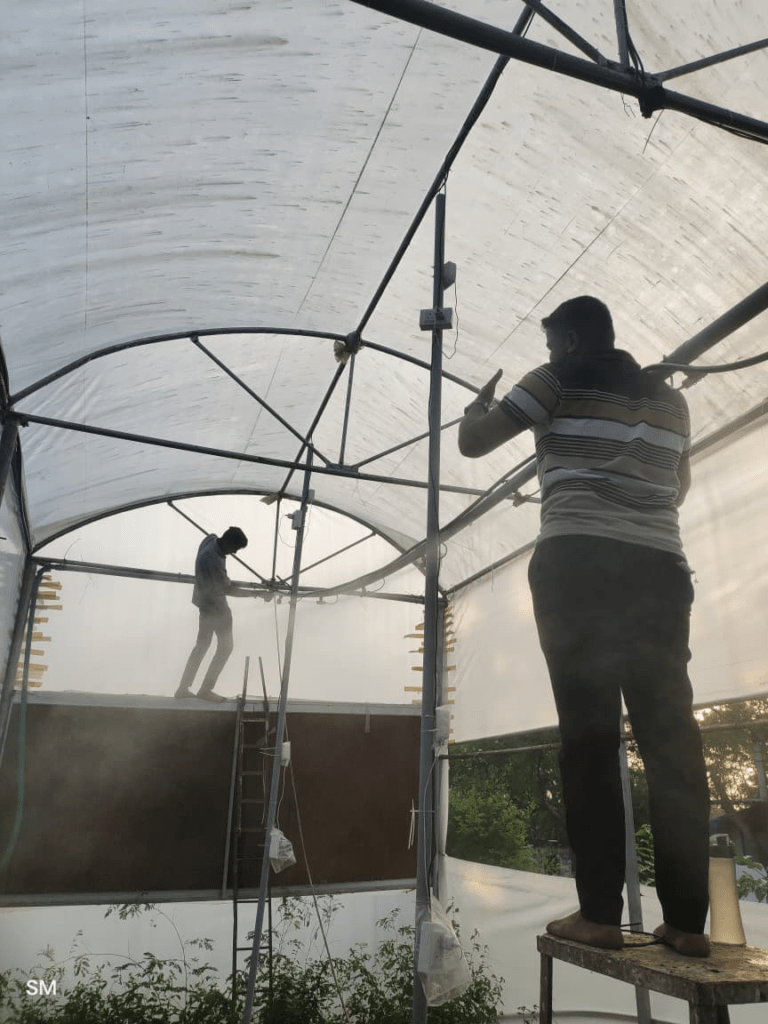

Before starting the trials, some basic arrangements were required inside the polyhouse. The first fogger to be tested was the turbo fogger, which operates with both water and air pressure.

For the turbo fogger system:

- Required water pressure: 4 kg/cm²

- Required air pressure: 2 kg/cm²

To achieve the required air pressure, an air compressor with an 8 kg/cm² capacity was connected to the system. The water and air lines were properly attached to supply pressure to the fogger units.

Testing and Observation:

During the initial trial, we tried to operate the system, but both the required water and air pressures could not be achieved due to minor leakages in the pipe connections. This affected the overall pressure buildup and performance of the fogger.

The next step is to identify and fix all leakage points to ensure the system runs smoothly and the foggers receive proper operating pressure. After solving this issue, the performance of turbo foggers will be tested again to record their efficiency and mist formation.

11/10/2025 to 12/10/2025

Observation and Issues Found:

During the first trial, the system failed to build up the required pressure because of leakages in the pipe connections. On checking carefully, we found that:

- The water flow pipe used was 50 mm

- The air transfer pipe was only 20 mm

Due to this uneven pipe size, proper air pressure could not be created, which affected the fogger performance.

System Modification and Redesign:

After discussion with Abhijeet Sir, we decided to reinstall the entire setup. The main changes made were:

- Replaced the air transfer pipe from 20 mm to 50 mm to balance pressure flow.

- Checked all fogger fittings and removed leakages.

- Reassembled and rechecked the full setup for any pressure loss.

During this process, I also studied how turbo foggers work and their principle of mixing air and water to create a fine mist.

Successful Operation and Visit:

After completing the modifications, we successfully operated the turbo foggers with the required pressures. The foggers produced a fine, uniform mist inside the polyhouse. Later, Dixit Sir and Ranjeet Sir also visited the site to observe the working of the turbo fogger system.

13/10/2025

First Trial – 13/10/2025

On 13th October 2025, I decided to take the first readings from the turbo fogger setup.

Before starting the trials, I discussed the trial plan with Abhijeet Sir to finalize the procedure.

The purpose of the first trial was to observe how much time is required for the temperature to drop using the turbo foggers and to record the corresponding changes in humidity and temperature inside the polyhouse.

For accuracy, I conducted two separate trials and recorded all readings. The data was then arranged in tabular form for further analysis.

- Procedure for Taking Readings in Polyhouse

Procedure for Taking Readings in Polyhouse

- Start the Water Motor:

- Turn on the water motor and allow the system to stabilize.

- Set the water pressure at:

- 3.5 bar at the water tank

- 4 bar on the fogger water line inside the polyhouse

- Start the Air Compressor:

- Switch on the air compressor and set the air pressure on the fogger line as required. (2 Bar)

- Begin the Trial:

- Once both pressures are properly set, start the actual trial.

- Close all polyhouse openings to minimize air and humidity losses.

- Before starting the trial note down the temperature and humidity at outside the polyhouse

- Record Observations:

- Continuously observe the temperature and humidity data using the datalogger.

- Note the time and changes in readings as the foggers operate.

- When Temperature Becomes Constant:

- After noticing a stable temperature drop, start the big fan to allow air circulation inside the polyhouse.

- Record the new temperature and humidity readings along with the time.

- During Fan Operation:

- Observe that temperature drops faster and humidity increases when the fan is ON.

- Continue noting readings until humidity reaches 100% and remains constant for 2–3 readings.

- End of Trial:

- Once the readings are stable, stop all equipment — motor, compressor, and fan.

- Open the polyhouse curtains to release the accumulated humidity and reset the environment for the next trial.

14/10/2025

Datalogger Maintenance and Polyhouse Modifications

Morning Session:

On 14th October 2025, I worked on repairing and updating two dataloggers by changing their Wi-Fi settings and passwords, preparing them for installation in the polyhouse.

After this, Abhijeet Sir and I discussed improvements in the polyhouse setup. Currently, the fanpad system is covered with a polythene sheet, which limits its flexibility. We planned to modify the setup so that the fanpads can be opened or closed as needed to improve ventilation control.

To implement this, I visited the market to purchase curtain angles and collected UPVC pipes for fitting and installation.

Afternoon Session:

In the afternoon, I resumed taking trials similar to the previous day to record temperature and humidity changes using the turbo foggers.

During the trial, however, there was an electrical short circuit in the main supply and board, which forced me to stop the trial early.

Despite this, the work done in repairing the dataloggers and preparing the polyhouse setup was completed successfully, and the system is ready for further trials after fixing the electrical issue.

15/10/2025 and 16/10/2025 – Electrical Setup Repair

After the short circuit issue faced during the previous trial, I spent 15th and 16th October 2025 repairing and restoring the damaged electrical setup in the polyhouse.

The main tasks completed during these two days were:

- Replacing the damaged MCB and electrical board.

- Changing the connection line of the current supply to ensure proper load distribution and safety.

- Checking all wire joints and tightening connections to prevent further short circuits.

After completing these repairs, the electrical system was tested successfully, and the polyhouse setup is now ready for the next fogger trials without any power interruption.

29/10/2025

28/10/2025 – Turbo Fogger Discharge Calculation

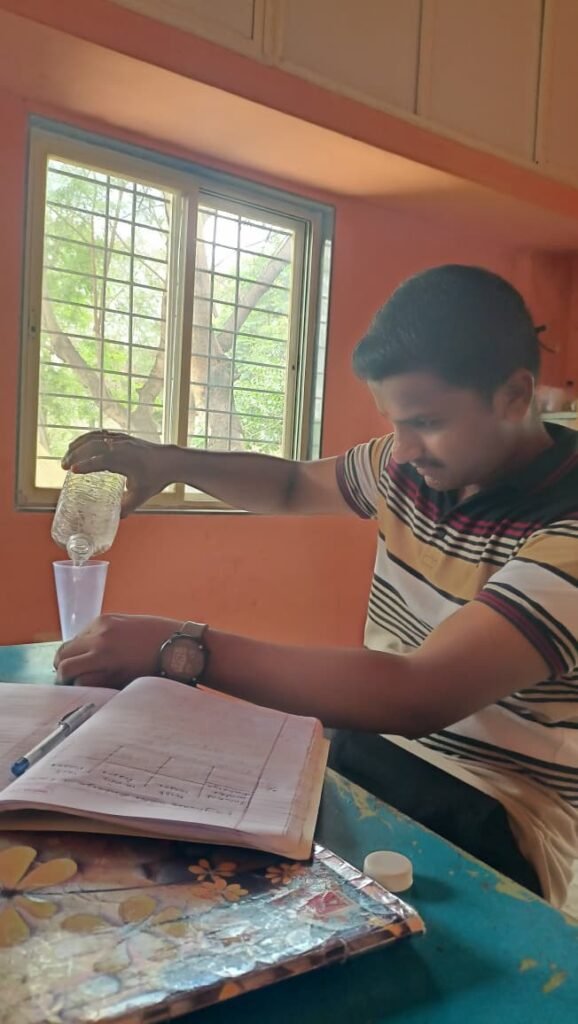

On 28th October 2025, I conducted an experiment to calculate the water discharge rate of turbo foggers inside the polyhouse.

For this experiment, I used empty plastic water bottles, which were cut from the top and fixed firmly on the fogger tips to collect the sprayed water.

Before starting the measurement, the system was operated for a short time to collect the initial water, ensuring that both air and water pressures were properly set and stable.

To get accurate readings, I attached three collection bottles at different points:

- First bottle: at the starting fogger

- Second bottle: at the middle fogger

- Third bottle: at the last fogger in the line

The foggers were operated for 5 minutes, and the amount of water collected in each bottle was measured.

From the 5-minute readings,

I calculated:

- The discharge per minute for each fogger

- And then the discharge per hour based on the 1-minute discharge value

This experiment helped in understanding the uniformity and efficiency of water output from turbo foggers under controlled pressure conditions.

Turbo Fogger Discharge in 5 min

| SR.NO | INITIAL WATER DISCHARGE | FIRST FOGGER | SECOND FOGGER | THIRD FOGGER |

| 1 | 90 ML | 330-90 = 240 ML | 310-90= 220 ML | 340-90= 250 ML |

THESE DATA IS FOR 5 MIN SO FOR 1 MIN

240 /5 = 48

220/5= 44

250/5 = 50

AVG OF THESE ABOVE NUMBERS = 48+44+50 / 3 = 47.33 APRROX 48 ML FOR 1 MIN = 0.048 L /MIN

FOR 1 HOUR = 0.048 X 60 = 2.88 L / HOUR FROM 1 FOGGER

FOR 8 FOGGER = 2.88 X 8 = 23.04 LIT / HOUR

29/10/2025

29/10/2025 – Temperature and Humidity Readings

On 29th October 2025, I conducted another set of temperature and humidity readings in the polyhouse using the turbo fogger setup, similar to the earlier trials.

The main objective of this trial was to observe changes in temperature and humidity after operating the turbo foggers for a specific duration. The readings were taken at regular time intervals to study how effectively the fogger system helps in cooling and maintaining humidity inside the polyhouse.

All recorded data was arranged systematically in tabular form for further comparison with previous trials, which will help in analyzing the overall performance and consistency of the turbo fogger system.

| TIME | INITIAL TEMPERATURE | WATER PRESSURE | AIR PRESSURE | TEME DROP | HUMIDITY | TIME | AIRCIRCULATION FAN START | TEMP DROP | HUMIDITY | TIME |

| 3.30 PM | 46.34 | 4 | 2 | 46.08 | 46.82 | 3.44 PM | 3.44 PM | 35.22 | 100 | 3.53 PM |