Introduction: A Small Step with a Climate Impact

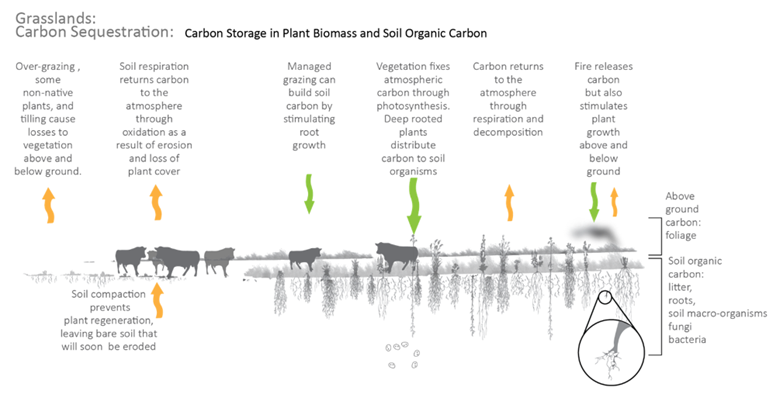

Grass and herbs are often seen as low-value biomass. However, when managed scientifically, they play a critical role in carbon sequestration and climate mitigation. Understanding biomass on a dry-matter basis is essential in plantation planning because carbon sequestration, productivity, and ecosystem modeling depend on stable biomass estimates rather than moisture-influenced fresh weight. Drying data helps identify plant species with higher structural carbon retention, optimize planting density, and forecast long-term carbon stocks. This approach reduces uncertainty in carbon budgeting, supports land restoration strategies, and aligns plantation design with emerging carbon credit and MRV (Measurement, Reporting, and Verification) frameworks.

1. Why Moisture is the Hidden Problem in Carbon Calculations

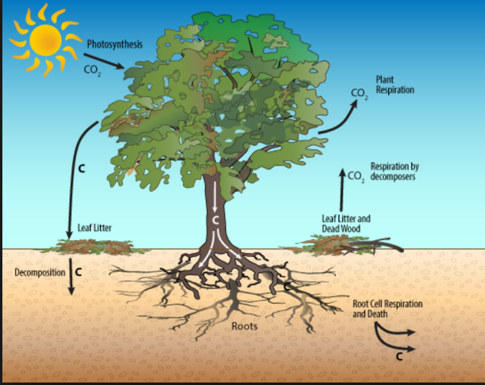

Fresh grass and herbs contain 70–85% moisture. While this water increases weight, it contributes no carbon. More importantly, moisture keeps the biomass biologically active, allowing respiration and microbial decomposition to continue.

As long as moisture remains:

- CO₂ is continuously released

- O₂ is consumed

- Carbon storage values remain unstable

For carbon accounting, this creates a serious error: wet biomass behaves like a carbon source, not a carbon sink.

2. Drying as a Carbon-Stabilization Process

Drying removes free moisture and converts biomass from a living system into a chemically stable material.

After drying:

- Respiration nearly stops

- Microbial activity is suppressed

- Carbon remains locked in plant polymers such as cellulose and lignin

This stabilization is crucial because carbon credit systems require fixed, measurable, and verifiable carbon stocks.

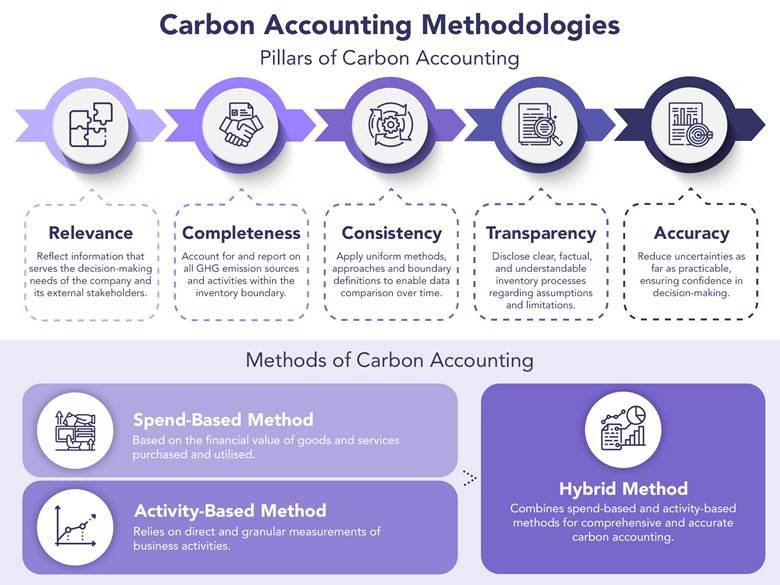

3. Linking Dry Biomass to Carbon Credits

Carbon credits are issued based on:

- Measurable carbon sequestration

- Permanence of carbon storage

- Verifiable data

Dry biomass fulfills these requirements because:

- Carbon content is calculated on a dry weight basis

- Results are repeatable across seasons

- Data aligns with MRV (Measurement, Reporting, Verification) frameworks

In grassland and agro-ecosystems, drying allows seasonal biomass to be quantified, preserved, and counted rather than lost to rapid decomposition.

4. Methodological Instructions for the Project.

The drying methodology follows a simple but powerful logic:

- Measure fresh biomass

- Dry to constant weight

- Determine dry matter content

- Estimate carbon fraction (≈45–50%)

- Convert to CO₂ equivalents

This approach transforms a local drying experiment into climate-relevant data.

5. Observations from Drying Grass and Herbs

- Faster drying reduces CO₂ loss from decomposition

- Uniform drying improves data consistency

- Controlled solar drying balances energy efficiency and biomass quality

- Dry biomass provides stable reference values for carbon estimation

6. Challenges and Limitations

Despite its potential, several obstacles remain:

- High humidity slows drying

- Lack of low-cost CO₂ sensors limits direct gas measurement

- Carbon credit frameworks still focus more on forests than grasslands

These gaps represent opportunities for innovation, especially in community-scale carbon projects.

7. Future Perspective: Scaling Drying into Climate Action

With standardized drying protocols, grass and herb biomass can:

- Support grassland carbon credits

- Strengthen climate-smart agriculture

- Enable rural participation in carbon markets

- Reduce biomass waste while improving soil carbon.

20th September

I started taking LOD (Loss on Drying) readings for the 14 Trees Foundations supplied samples. From 26 total samples (13 grasses and 13 herbs), I finished the readings for 16 samples.

21st September

I made the rest of the 10 LOD readings of the given by 14 trees Foundation.

26th September

I began my dome dryer experiment using the materials sent by the 14 Trees Foundation. Following consultations with Prasad Sir, I filled the dryer gently in order to start the operation.

29th September

I also began measuring the dome dryer trials in progress as an additional parameter, Solar Illuminance, following consultation with Prasad Sir.

30th September

I finished measuring the dome dryer pilot test outcomes and, at the same time, researched parameters concerning potential chemical treatments for onion storage.

1st October

I informed the trials updates to Yogita Ma’am of the 14 Trees Organization about the ongoing trials.

3rd October

In the evening, I measured the final weight of the samples provided by the 14 Trees Foundation. The results showed an overall drying of 70%, with the weight reducing from 8.595 kg to 2.515 kg.

The final report in the Excel is given below-

https://docs.google.com/spreadsheets/d/11jxKdvepP5IyXq9wdFWpSPLmL9xyeP72Lr8SrVv8PyE/edit?usp=sharing

8th October

Calculated the final moisture loss and drying efficiency of the 14 Trees Foundation samples based on previous measurements.

9th October

Discussed the results and drying observations with Yogita Ma’am from 14 Trees Foundation to ensure data accuracy and to plan the next phase of testing.

Trial of Subabul in the Inclined Dryer

17th October

In the discussion, Yogita ma’am told me about their tentative date for the next sample for the second trial.

But due to the holiday of Diwali, there is no availability for manpower to load and measure the data daily. It took nearly 1 and a half hours to measure daily and to load more than 3 hours with 5 people, except the LOD calculations for 70 samples nearly 1-2 days.

So the trial will be after the Diwali festival. However, we don’t have the data for the inclined dryer. For that, I prepared the subabul trial on it with 160g in each tray; likewise, it has 39 trays, so it contains 6240g of subabul leaves. i place the sample tray on tree trays of each section. It has 4 sections means 12 trays total. One is on the upside, downside, and one is in the middle holding 30g on each sample of 1 square foot.

The placement of the date logger is in the middle of the drying zone on trays 1(DIC-5) and 4. (dryer 3)

The losses of the subabul leaves are as follows –