01/04/2025 – 02/04/2025

INTRODUCTION:

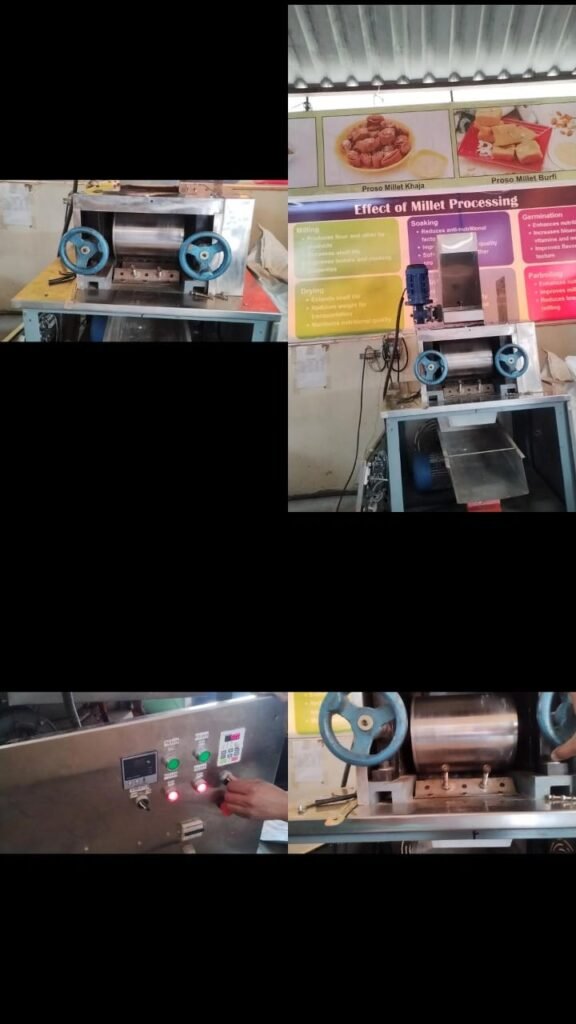

Agrozee Organics Pvt. Ltd. is engaged in the processing of multi-grain flakes, with a focus on producing nutritious food products such as sorghum flakes. However, during recent trials and machine inspections, it was observed that the multi-grain flakes machine installed at the facility is not functioning optimally. The machine is unable to produce consistent flakes from sorghum, which affects the quality and uniformity of the final product.

To address this issue, a field visit was conducted to assess the condition and working of the machine. During the visit, a test trial was carried out in which sorghum was steamed for 45 minutes to soften the grains, followed by drying in a heat pump to remove excess moisture. Despite this controlled preparation process, the machine still failed to deliver consistent flaking results. This indicates that the root cause of the problem is likely mechanical in nature.

The inconsistency in flake production not only leads to product wastage but also affects overall process efficiency, productivity, and product quality. Therefore, there is a clear need to analyse and resolve the mechanical problems in the machine to ensure smooth and effective operation.

The objective of this project is to:

Investigate the operational limitations of the current multi-grain flakes machine.

Identify and diagnose the mechanical faults affecting flake consistency.

Propose practical solutions or design improvements for achieving better flaking performance, particularly for sorghum.

Help Agrozee Organics improve their product quality, production output, and reduce material wastage.

Here i visit to the Agrozee Organics

I use the process as follow:

Flow chart:-

First i soak the swarghum (jawari) in to the water for 18hrs to soften the jawari

↓

after that i give steam to the jawari for 45 min

↓

placed at heat pump for remove moisture after steaming

↓

after that swarghum feed into feeder

↓

and the jawari are flaked

Here is the my observations:

- Some Jawari goes out of the roller and damaged.

- Some are passed through roller and flaked.

- After flaked the some jawari gets proper shaped some get over flaked and some get not flaked properly.

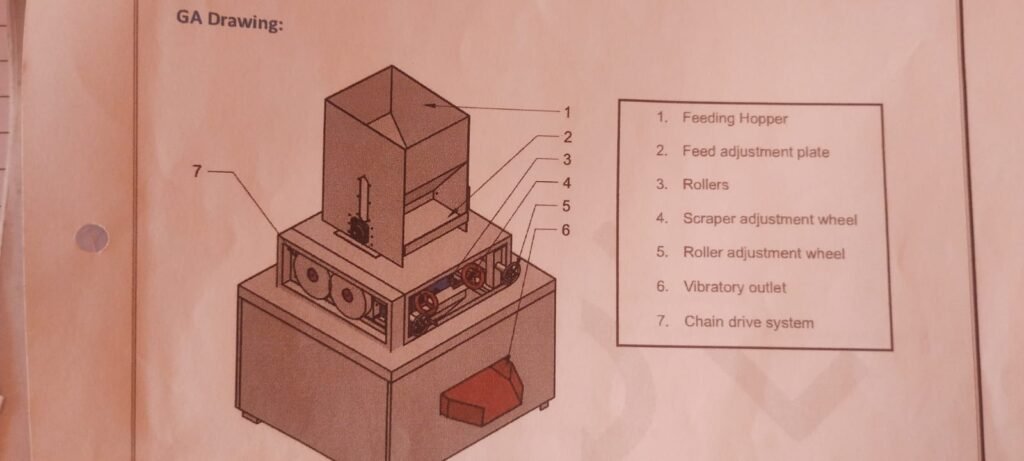

- And have a technical problems of roller, scrapper, and the feeding adjustment and damage control

Visit Report:- VISIT_REPORT_Uralikanchan[1].docx

Conclusion:

We have send this visit report to the Agrozee Organics pvt ltd. but we don’t have any respond from them.

“I discuss it with Dixit Sir and Prasad Patil Sir. If Agrozee is able to pass on the necessary information to us, we will proceed accordingly.”

The discussion is done with the Agrozee Organics pvt ltd. they are able to deliver the Multi Grain Machine to Vigyan Ashram.

25/04/2025

Today, the multigrain flake machine arrived at Vigyan Ashram. Agrozee Organics sent this machine.

The further trials are taken by myself in upcoming days were i use this method

26/04/2025

First i soak 1kg the swarghum (Jalgaon) in to the water for 3hrs to soften the jawari

↓

after that i give steam to the jawari for 45 min

↓

placed at heat pump for remove moisture after steaming (for 40min, at 50°C )

↓

But due to 3 phase machine the connection was not taken on that day first i connect the machine with the help of K.V.Jadhav Sir on 27/04/2025

27/04/2025

I take a trial on swarghum (Jalgaon)

↓

500gm soaked in 700ml water (3hrs)

↓

Final wt. after soaking is 543gm

↓

Steamed for 1hr in steamer

↓

Dried for 1 hr at 50°C (576gm)

↓

Take a trial on swarghum with guidance of Abhijeet sir

The result was quite well

| Good Flack | 30% |

| Sticked Flack | 15% |

| Over Flack | 20% |

| Semi Flack | 25% |

| Not Flack | 10% |

28/04/2025

Multi grain Machine

I take a trial on swarghum (Jalgaon variety)

↓

500gm soaked in 700ml water (18hrs)

↓

Final wt. after soaking is 566gm

↓

Steamed for 1hr in steamer

↓

after steam wt.786gm

↓

Dried for 1 hr at 50°C (546gm)

↓

Take a trial on swarghum with guidance of Abhijeet sir

LOD = (WET WT. – DRY WT.)

= 786gm – 546gm

LOD = 240gm

LOD% = (LOSS / WET WT.) *100

LOD% = 240/786*100

LOD% = 30.53%

Result:

| Good Flack | 126gm | 23.08% |

| Sticked Flack | 40gm | 7.33% |

| Over Flack | 146gm | 26.76% |

| Semi Flack | 35gm | 6.41% |

| Not Flack | 108gm | 19.78% |

| Damaged Flack | 91gm | 16.67% |

30/04/2025

I take a trial

Flow Chart:-

Soak a 500gm of swarghum for 1hr (515gm)

↓

Boil it with 1000gm water for 35min(888gm)

↓

Placed into dryer for 70min at 55°C (570gm)

↓

After that feed into feeder for flack

Result:-

| Good Flack | 33% |

| Sticked Flack | 12% |

| Over Flack | 20% |

| Semi Flack | 23% |

| Not Flack | 12% |

Discussion with Dixit sir on the thickness of market flack and the gap between the roller.

04/05/2025

Make a full factorial design on

1)Soaking

2)Cooking

3)Drying

03/05/2025

I take a trial

Flow Chart:-

Soak a 500gm of swarghum for 24hr (596gm)

↓

Steamed it with for 45min(895.8gm)

↓

Placed into dryer for 120min at 55°C (681.4gm)

↓

After that feed into feeder for flack

But their are Not steamed well ,I have to upgrade the container to steaming

09/05/2025

Multi grain readings of the market flack-

| Sample No | Thickness in (mm) | Weight (gm) | Length (mm) | Width (mm) |

| 1 | 0.95 | 0.032 | 7.74 | 6.17 |

| 2 | 0.85 | 0.036 | 7.99 | 5.90 |

| 3 | 0.69 | 0.033 | 9.08 | 6.18 |

| 4 | 0.81 | 0.036 | 7.99 | 7.13 |

| 5 | 0.63 | 0.034 | 8.02 | 7.20 |

| 6 | 1.07 | 0.028 | 6.50 | 5.78 |

| 7 | 0.78 | 0.035 | 7.10 | 5.55 |

| 8 | 1.32 | 0.038 | 6.73 | 6.32 |

| 9 | 0.36 | 0.021 | 10.93 | 7.99 |

| 10 | 0.89 | 0.031 | 6.88 | 6.00 |

| ∑ = 8.41 | ∑ =0.032 | ∑ =78.96 | ∑ =64.2 | |

| Average=0.84 | Average=0.032 | Average=7.89 | Average=6.42 |

To measure the distance between roller

I took Paper 0.74mm for that paper goes throw the Roller

| Length of stationery roller 24 groows | |

| Left | Right |

| 0.74mm paper Didn’t goes if groows ’20’ | 0.74mm paper Didn’t goes if groows ’20’ |

| 0.74mm paper goes if groows ’21’ | 0.74mm paper goes if groows ’21’ |

10/05/2025

Multi grain readings of our flack-

| Sample No | Thickness in (mm) | Weight (gm) | Length (mm) | Width (mm) |

| 1 | 0.22 | 0.040 | 20.79 | 9.16 |

| 2 | 0.34 | 0.029 | 9.48 | 6.68 |

| 3 | 0.28 | 0.035 | 16.20 | 7.40 |

| 4 | 1.03 | 0.028 | 6.18 | 5.17 |

| 5 | 0.69 | 0.030 | 8.24 | 5.32 |

| 6 | 1.05 | 0.047 | 7.20 | 6.44 |

| 7 | 0.36 | 0.032 | 13.70 | 7.40 |

| 8 | 0.82 | 0.033 | 8.90 | 6.40 |

| 9 | 0.61 | 0.014 | 9.46 | 6.58 |

| 10 | 0.09 | 0.032 | 27.16 | 5.04 |

| ∑ = 6.31 | ∑ =0.358 | ∑ =136.76 | ∑ =71.93 | |

| Average=0.57 | Average=0.032 | Average=12.43 | Average=6.53 |

Soak grain for the preparation or calculation of the LOD.

Soak 500 grams of sorghum in 600 ml of water for 4 hours (final weight: 696 grams).

↓

boiled it with for 40min(1002gm)

↓

Placed for dry for 24hrs at room temperature (626.7gm)

↓

After that feed into feeder for flack

11/05/2025

I make a calculation

Soaking time = 4hrs

Given-

Initial wt.=500gm

Final Wt. = 676gm

- Water present After Soaking = Final Wt. – Initial Wt.

Water present After Soaking = 676gm-500gm

Water present After Soaking = 176gm

2. % Moisture content After Soaking = Water present wt./ Initial wt.×100

% Moisture content After Soaking = 176/500×100

% Moisture content After Soaking =35.2%

3. % wt. of water after boiling

Given,

Initial wt. =500gm

wt. gained after boiling = 502gm + Initial wt.

% wt. of water after boiling = Wt. gained /wt. of sample × 100

% wt. of water after boiling = 502/500×100

% wt. of water after boiling =100.4%

4. LOD % = Wt. loss/ Wt. of sample×100

Given-

Wt. loss = 377gm

Wt. of sample = 500gm

LOD % = Wt. loss/ Wt. of sample×100

LOD % = 377/500×100

LOD % = 75.4%

Conclusion –

At 25% moisture, the flakes are well-formed, just as we want them

Also we have to take a trial to adjust the moisture content.

Observation-

Some of the grain are not steamed well in the core

| Sample no. | Thickness (mm) | Weight (gm) | Length (mm) | Width (mm) |

| 1 | 0.53 | 0.033 | 10.39 | 7.08 |

| 2 | 0.50 | 0.022 | 10.94 | 5.97 |

| 3 | 1.25 | 0.036 | 6.38 | 6.31 |

| 4 | 0.92 | 0.029 | 7.01 | 4.76 |

| 5 | 0.96 | 0.031 | 6.81 | 5.61 |

| ∑= 4.16 | ∑= 0.151 | ∑= 41.53 | ∑= 29.73 | |

| Avg = 0.832 | Avg = 0.030 | Avg = 8.306 | Avg =5.946 |

After that we have to check the water holding capacity

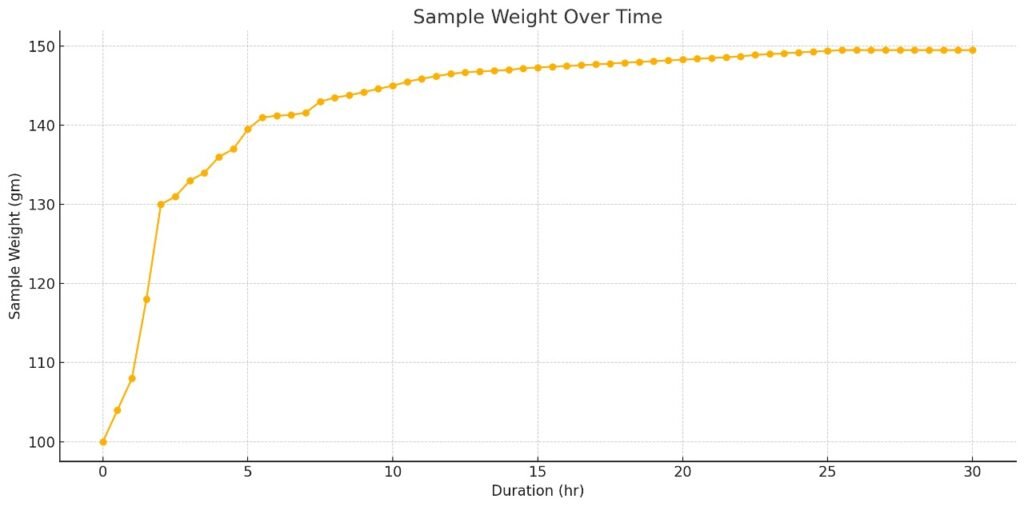

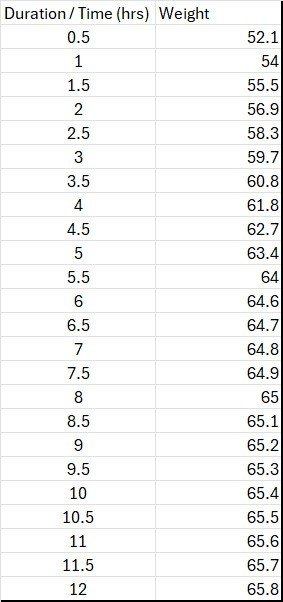

12/05/2025 – 13/05/2025

Sample wt.=100gm

Water = 200gm

I recorded water soaking measurements every 30 minutes for a total duration of 30 hours.

Soak 100 grams of sorghum for 30hrs (final weight:149.5grams).

↓

Steamed it with for 40min(189gm)

↓

Placed for dry for 4hrs at room temperature (125gm)

↓

After that feed into feeder for flack

Observation –

Some of the grain are nor steamed well in the core

| Sample no. | Thickness (mm) | Weight (gm) | Length (mm) | Width (mm) |

| 1 | 0.52 | 0.033 | 12.08 | 6.68 |

| 2 | 0.84 | 0.022 | 7.19 | 6.13 |

| 3 | 0.88 | 0.036 | 8.65 | 6.80 |

| 4 | 0.94 | 0.029 | 9.71 | 7.23 |

| 5 | 1.07 | 0.031 | 8.18 | 7.60 |

| ∑= 4.25 | ∑= 0.151 | ∑= 45.81 | ∑= 34.44 | |

| Avg = 0.85 | Avg = 0.030 | Avg = 9.162 | Avg =6.88 |

Conclusion – From this graph we have decide the soaking period is 6hrs respectively.

Some of the grain are not steamed well in the core

16/05/2025

I make a Graphical representation

Also discuss with Dixit sir About steaming process

soak the grains of swarghum (100gm)

Where we have a conclusion, use the the steel mesh or make a design of

17/05/2025

Today i work on the Steaming protocol

were i, Soak 100 grams of sorghum for 6hrs (final weight:145grams).

↓

Steamed it with for 45min(214.7gm)

↓

Placed into Flat bed dryer for 5hrs at 48°C (118.5gm)

↓

After that feed into feeder for flack

Observation-

Some are not flacked

Due to low moisture content (18.5%) the sorghum Flacked but they stretched back.

We only check the distance between roller rod and wheel rod is 41:42, Left and Right respectively.

Conclusion –

We have to maintain only 25% Moisture Content.

Below 25% MC flacks are not flacked well.

19/05/2025

I made notes on the multigrain flake machine based on past trials and discussed them with Agrozee Organics Pvt. Ltd.

20/05/2025

Make a trial for another perfect and best trial for Moisture Content (25%)

Soaked for the 6hrs (100gm—— 146gm)

↓

Steamed for 46min (146gm——174.7gm)

↓

Room Temperature drying

↓

But due to some rainy season the they are not well dried at (Moisture Content 25%)

Observation :-

However, due to the rainy season, the flakes were not properly dried and retained a high moisture content of around 55%(155gm).

24/05/2025

Take a trial on the sorghum

Make a trial for another perfect and best trial for Moisture Content (25%) steamed in the container for 45min

Soaked for the 6hrs (100gm—— 136gm)

↓

Steamed for 45min (136gm——177gm)

↓

Dried for 30 min electric dryer at 50°C (20%Moisture content)

↓

But the grains are not steamed well that’s why they are powdered slightly

Observation:-

- The grains are flacked and in the core of grain gets powdered

- At moisture content 20% the grains are not flacked properly

Conclusion:-

- At moisture 20% the flacks are not in shape.

- Also measure the rollers that are aligned in parallel.

25/05/2025

Take a trial on the sorghum

Soaked for the 6hrs (100gm—— 146gm)

↓

Steamed for 1hr in container (146gm——178gm)

↓

Dried for 25 min electric dryer at 50°C (33.3%Moisture content)(178gm——133.3gm)

↓

take a trail on the steamed sorghum

Observation:-

- They are steamed well.

- Flacks are sticked to the roller at moisture content 33.3%

Conclusion:-

- The 33.3% moisture content was very high for trail of the sorghum flack.

26/05/2025

Take a trial on the sorghum

Soaked for the 6hrs (100gm—— 145gm)

↓

Steamed for 1hr in pressure cooker at 5 vessels (145gm——165gm)

↓

Dried on gas for 7min high flame (20.6%Moisture content)(165gm——120.6gm)

↓

take a trail on the steamed sorghum

Observation:-

- The sorghum was to hard because of the direct heat to the some part of the grain.

- They are stretched back.

Conclusion:-

- Dried after steaming into electric dryer for better trail.

27/05/2025

Take a trial on the sorghum

Soaked for the 6hrs (100gm—— 142.4gm)

↓

Steamed in pressure cooker at 5 vessels and place this 142.4gm of sorghum into the net have shape of rectangle (142.4gm——180gm)

↓

Dried for 30min at moisture content 30% (30%Moisture content)(180gm——130gm)

↓

take a trail on the steamed sorghum

Observation:-

- The scraper affect to the roller

- Material stick to the roller

Conclusion:-

- The moisture content was slightly high for flack

- we final the 25% Moisture Content and also take a trail on the 25%

28/05/2025

Take a trial on the sorghum

Soaked for the 6hrs (100gm—— 146gm)

↓

Steamed in pressure cooker at 5 vessels and place this 146gm of sorghum into the net have shape of rectangle

(146gm——173.7gm)

↓

Dried for 30min at moisture content 25% (25%Moisture content)(173.7gm——125gm)

↓

take a trail on the steamed sorghum

Observation / Conclusion:-

- The moisture content 25% is ideal for the trail on the sorghum for flack

- Sorghum was best in the form the distance was left-41.25mm & right-42.44mm

- The feed rate was consistent, if we feed more sorghum they are not flacked as we want

- In this we get the best result

- The grains are not over flacked

30/05/2025

Take a trial on the sorghum

Soaked for the 6hrs (100gm—— 143gm)

↓

Steamed in pressure cooker at 5 vessels and place this 143gm of sorghum into the net have shape of rectangle(45min)

(143gm——177gm)

↓

Dried for 40 min at 50°C

↓

take a trail on the steamed sorghum

Observation:-

- Over dried the sorghum grain.

- The grain gets hard.

- It’s not flack well.

Conclusion:-

Maintain the temperature and time properly for drying.

03/06/2025

Take trail,

Soaked for the 6hrs (100gm—— 141gm)

↓

Steamed in pressure cooker at 4vessels and place this 141gm of sorghum into the net have shape of rectangle(31min)

(141gm——153gm)

↓

Dried for 20 min at 50°C

↓

take a trail on the steamed sorghum

Observation:-

- The steam not going on the core of the sorghum.

- They are not steamed well.

Conclusion:-

Due to flacks are saturated in drying process, we have to dry the flacks instant/ quickly.

- Iron the flack direct drying.

- And dry in electric dryer quickly.

08/06/2025

Soaked for the 6hrs (100gm—— 139gm)

↓

Steamed in pressure cooker at 6vessels and place this 139gm of sorghum into the net have shape of rectangle(31min)

(139gm——172gm)

↓

Dried for 20 min at 50°C (136gm)

↓

take a trail on the steamed sorghum

Observation, Conclusion:-

- Flacks are well flacked

- Flacks are dried at 50°C for 2hrs

- Saturate the flack after drying for that

- ……….

09/06/2025

Soaked for the 6hrs (100gm—— 146gm)

↓

Steamed in pressure cooker at 6vessels and place this 146gm of sorghum into the net have shape of rectangle(28min)

(146gm——164.6gm)

↓

Dried for 25 min at 45°C (149gm)

↓

take a trail on the steamed sorghum

↓

And after Flacking i move the flacks into the dryer for drying at 55°C for 30min

Observation, Conclusion:-

In the dryer they get quick dried the outer surface of the sorghum that’s why they are not stick to the each other

- Well flacked – 70%

- Powder – 5%

- Over flack – 25%

10/06/2025

Soaked for the 6hrs (100gm—— 140.7gm)

↓

Steamed in pressure cooker at 6vessels and place this 140.7gm of sorghum into the net have shape of rectangle(30min)

(146gm——173.9gm)

↓

Dried for 25 min at 45°C (146gm)

↓

take a trail on the steamed sorghum

↓

And after Flacking i move the flacks into the dryer for drying at 55°C for 30min

Observation, Conclusion:-

In the dryer they get quick dried the outer surface of the sorghum that’s why they are not stick to the each other

- Well flacked – 75%

- Powder – 5%

- Over flack – 20%

11/06/2025

Soaked for the 6hrs (100gm—— 141.3gm)

↓

Steamed in pressure cooker at 6vessels and place this 141.3gm of sorghum into the net have shape of rectangle(30min)

(141.3gm—–170.6gm)

↓

Dried for 25 min at 45°C (152gm)

↓

take a trail on the steamed sorghum

↓

And after Flacking i move the flacks into the dryer for drying at 55°C for 30min

Observation, Conclusion:-

In the dryer they get quick dried the outer surface of the sorghum that’s why they are not stick to the each other

- Well flacked – 82%

- Powder – 5%

- Over flack – 13%

Wt. after the drying of the flacks was 98.7gm

14/06/2025

Soaked for the 6hrs (100gm—— 139.7gm)

↓

Steamed in pressure cooker at 6vessels and place this 139.7gm of sorghum into the net have shape of rectangle(30min)

(139.7gm—–160.6gm)

↓

Dried for 25 min at 45°C (144.2gm)

↓

take a trail on the steamed sorghum

↓

And after Flacking i move the flacks into the dryer for drying at 55°C for 28min

Observation, Conclusion:-

In the dryer they get quick dried the outer surface of the sorghum that’s why they are not stick to the each other

- Well flacked – 77%

- Powder – 5%

- Over flack – 13%

- Not flacked – 5%

Wt. after the drying of the flacks was 98.8gm

16/06/2025

Agrozee Organics owner send their sorghum for trial

Here is the result for Sorghum,

Soaking test –

soaked for 12hrs and take a reading.

17/06/2025

Take a trial on new sorghum,

Jowar (50gm)

↓

Soaked (65.5gm/6hr approx.)

↓

Steaming (88gm/5 vessels)

↓

Drying (73.6gm 45°C for20min)

Observation:-

Moisture was high for the trial to make a flacks.

Sticky – 35%

Well flack – 55%

Over Flack – 10%

20/06/2025

This is 2nd trial on sorghum,

In this i make a spacer to adjustment of the wheel (0.84mm)

Take a trial by adjusting wheel by spacer,

Jowar (50gm)

↓

Soaked (69.2gm/8hr approx.)

↓

Steaming (76.3gm/5 vessels)

↓

Drying (68gm 45°C for20min)

Observation:-

In the trial taken using a spacer, the grains did not even flake properly.

Conclusion:-

Make a spacer which have thickness of below (0.84mm)

21/06/2025

This is 1st trial on Bajra,

In this i make a spacer to adjustment of the wheel (0.84mm)

Take a trial by adjusting wheel by spacer,

Bajra (50gm)

↓

Soaked (72.2gm/8hr approx.)

↓

Steaming (82.3gm/5 vessels)

↓

Drying (68gm 45°C for20min)

Observation:-

The grains are over dried to flack.

Conclusion:-

Make a dried protocol.

23/06/2025

This is 3rd trial on sorghum,

In this i make a spacer to adjustment of the wheel (0.62mm)

Take a trial by adjusting wheel by spacer,

Jowar (50gm)

↓

Soaked (64gm/6hr approx.)

↓

Steaming (75.3gm/5 vessels)

↓

Drying (71gm 45°C for20min)

Observation:-

In the trial taken using a spacer, the grains flake properly.

The shell of the grains is very hard to flack properly its gets cut in process of flack

Make a spacer which have thickness of below (0.62mm)

25/06/2025

The founder of Agrozee Organics visited Vigyan Ashram for further discussions. A detailed conversation was held regarding the flaking machine. It was decided to prepare an SOP for various millet grains. The need to achieve thiker flakes and improve grain cooking was highlighted. Agrozee Organics will be sending polished jowar and bajra for further trials.

02/07/2025

The shipment of polished grains has reached Vigyan Ashram.

The further trial are taken on that,

Take a trial by adjusting wheel by spacer, on first old grain

Jowar (50gm)

↓

Soaked (63gm/6hr approx.)

↓

Steaming (69.3gm/8vessels)

↓

Drying (67.4gm 45°C for20min)

Observation :-

Nothing changed in this trial.

04/07/2025

1st trial on Polished grain was taken by Aditya Joshi Beacouse my personal leave,

Jowar (50gm)

↓

Soaked (97gm/6hr approx.)

↓

Steaming (105gm/31min)

↓

Drying (88gm 45°C for20min)

Observation :-

- The grain is very white in color, resulting in white-colored flakes.

- Due to excessive soaking, the moisture content in the flakes is high, causing them to stick to the rollers and become mushy.

05/07/2025

2nd trial on Polished grain,

Jowar (50gm)

↓

Soaked (97gm/6hr approx.)

↓

Steaming (101gm/31min)

↓

Drying (78gm 45°C for25min)

Observation :-

- He grains were properly steamed, resulting in a soft texture.

- However, the moisture content remained high, making it difficult to produce proper flakes.

07/07/2025

3rd trial on Polished grain,

Jowar (50gm)

↓

Soaked (72gm/6hr approx.)

↓

Steaming (102gm/31min)

↓

Drying (62gm 55°C for 40min)

Observation :-

- The grains are over-dried, making them too hard.

- Due to their hardness, the grains are difficult to flake properly.

09/07/2025

Take a 1st trial on the Polished Bajara,

Bajara (50gm)

↓

Soaked (69gm/6hr approx.)

↓

Steaming (93gm/31min)

↓

Drying

Observation :-

- The grains become mushy and stick together during steaming.

- This affects the flaking process and results in poor-quality flakes.

11/07/2025

Take a 4th trial on the Polished Jowar,

Jowar(50gm)

↓

Soaked (66.62gm/6hr approx.)

↓

Steaming (70.05gm/31min)

↓

Drying (63.7gm)

Observation :-

- The grains become good and unstick during steaming.

- Flaking process and results in quality flakes.

13/07/2025

Take a 2nd trial on the Polished Bajara,

Bajara (50gm)

↓

Soaked (72.21gm/6hr approx.)

↓

Steaming (70.1gm/31min)

↓

Drying (64.1gm)

Observation :-

- The grains become mushy and stick together during steaming.

- This affects the flaking process and results in poor-quality flakes.

14/07/2025

Take a 5th trial on the Polished Jowar,

Jowar(50gm)

↓

Soaked (68gm/6hr approx.)

↓

Steaming (84gm/31min)

↓

Drying (70gm)

Observation:-

- To check the Moisture content and And the change in the behaviour in the flake of the grain.

- From this trial i determine the efficiency of the Flake is arount (65%-75%)

16/07/2025

We had a call with Vidya Mam (Agrozee Organics) about further trial they want mass batch (sample) of the Jowar.

The want a mass sample of it.

I work on it with mass sample trial

18/07/2025

Take a 1st mass trial on the Polished Jowar,

Jowar(1000gm)

↓

Soaked (1362gm/6hr approx.)

↓

Steaming (1420gm/31min)

↓

Drying (1268gm)

↓

Flake(15min)

↓

Drying (45°C for 50 min)

Observation:-

- The grain is well steamed and well flaked.

- They dried after flaking at 45°C for 50min.

- The trial is taken with presence of Dr.Dixit Sir.

The sample were Packed and some flake are fried and remaining are dispatched and parceled to Agrozee Organics pvt.ltd

26/07/2025

The sample reached to them,

They say that there is no difference between they make the flake & we make the flake.

The trial were stoped.

Closed this project because the work was completed.