google form-

Email ID –

siddhantsaid@gmail.com

Title of project –

Lemongrass Oil Distillation.

Responsible Person –

Siddhant Vishwas Said.

Introduction/ Background/Need of Project-

Introduction-

The lemongrass distillation project focuses on extracting essential oil from Cymbopogon (flexuosus, citratus). This oil is widely used in aromatherapy, cosmetics, and traditional medicine.

Background-

It involves steam distillation, where steam passes through the plant material, carrying essential oil to a condensation tube, where they condense into liquid form.

Need-

- High demand in cosmetics, pharmaceuticals, and food industries.

- Known for its antifungal, antibacterial, and anti-inflammatory properties.

- Promotes sustainable agriculture with low-maintenance crops.

- Provides income opportunities for farmers in suitable regions.

Objectives (write point by point) / Idea/ Methodology –

Objectives-

- Design high efficient lemongrass distillation unit.

- Extract good quality essential oil.

- Promote environmentally friendly agricultural practices.

Idea-

Make high efficient distillation unit & produce good-quality essential oil meeting the growing

global demand for natural products.

Methodology-

- Design efficient distillation Unit.

- Purchase & Fabricate the whole distillation system.

- Test the system by taking Rigorous trials.

- Set up distillation units near cultivation sites.

- Extract lemongrass oil.

- Test oil for purity and compliance with standards.

- Research to improve techniques and processes.

Client & Funding details –

Dr. Arun Dixit, Ranajeet Shanbhag.

Possible end-users –

Tejas dharave, Amey Kulkarni.

Starting date & Ending date-

24 Jun 2024 to ————.

Lemongrass Oil Distillation Unit

Project Objectives

- Design a functional and efficient distillation unit for extracting lemongrass oil.

- Source and assemble materials for the distillation unit.

- Operate the unit safely and effectively to produce lemongrass oil.

- Analyze and store the distilled oil properly.

Step 1: Understanding the Distillation Process

Basics of Steam Distillation

- Steam distillation is the preferred method for extracting essential oils from plants.

- The process involves passing steam through plant material, evaporating the essential oils, and then condensing the vapor back into liquid.

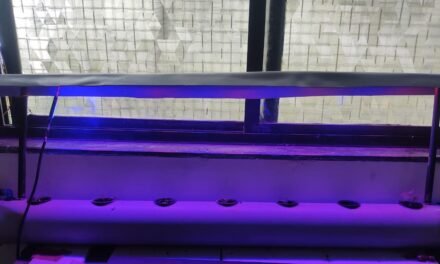

Step 2: Designing the Distillation Unit

Components of a Distillation Unit

- Boiler: Produces steam.

- Distillation Chamber: Holds the plant material.

- Condenser: Cools the steam back into liquid.

- Separator: Separates the essential oil from the condensed water.

Design Considerations

- Capacity: Determine the amount of plant material you want to process in each batch.

- Materials: Use stainless steel or glass for components in contact with the oil to avoid contamination.

- Safety: Ensure the design includes pressure release valves and sturdy construction to handle high temperatures and pressures.

Step 3: Sourcing Materials

Boiler

- Options: Stainless steel pressure cooker or commercial steam generator.

- Requirements: Must be able to produce consistent steam pressure.

Distillation Chamber

- Options: Stainless steel or glass container with a tight-fitting lid.

- Requirements: Large enough to hold the chopped lemongrass, with an inlet for steam and an outlet for vapor.

Condenser

- Options: Copper or stainless steel coil, or a commercial condenser.

- Requirements: Efficiently cools the vapor into liquid.

Separator

- Options: Glass or stainless steel separator funnel.

- Requirements: Allows easy separation of oil from water based on density differences.

Step 4: Assembling the Distillation Unit

Step-by-Step Assembly

- Boiler Setup:

- Connect the steam outlet of the boiler to the inlet of the distillation chamber using heat-resistant tubing.

- Distillation Chamber Setup:

- Securely fix the lid to the distillation chamber to prevent steam from escaping.

- Ensure there is an outlet at the top of the chamber connected to the condenser inlet.

- Condenser Setup:

- Position the condenser so that the steam outlet from the distillation chamber feeds into it.

- Ensure the condenser has adequate cooling, either through air circulation or water cooling.

- Separator Setup:

- Connect the outlet of the condenser to the separator.

- Position the separator to allow for easy collection of the distilled oil and water.

Step 5: Operating the Distillation Unit

Preparation

- Chop the Lemongrass: Cut the harvested lemongrass into small pieces.

- Load the Chamber: Fill the distillation chamber with the chopped lemongrass.

Distillation Process

- Heat the Boiler: Turn on the heat source to produce steam.

- Steam Flow: Allow the steam to pass through the distillation chamber, extracting the essential oil.

- Condensation: The steam carrying the oil vapor will pass through the condenser and cool into liquid.

- Separation: The liquid flows into the separator, where the oil and water separate based on density.

Safety Tips

- Always monitor the temperature and pressure to prevent accidents.

- Use heat-resistant gloves and safety goggles during operation.

- Ensure good ventilation in the workspace to avoid inhaling fumes.

Step 6: Post-Distillation Processing

Filtration

- Filter the collected oil to remove any impurities or plant residues.

Storage

- Store the lemongrass oil in dark glass bottles to protect it from light and degradation.

- Keep the bottles tightly sealed and store them in a cool, dry place.