Retort packaging is preservation technique mainly used for, Highly Perishable Food But it requires Highly Expensive Machineries. The Aim of Present Study is this technology Provide for Small scall Start up and home Appliances.

Introduction:

What is retort?

Retort Is Process method that use heat and Pressure to Sterilize food It is one of the most commonly use method of thermal food processing Popular with food producer across the world.

Shelf life of a food is integrally related to its packaging and the product conditions. The major driving forces for innovation in food packaging technology had increased due to the rise in consumer demands. Retort technology systems use steam or superheated water to cook food in its own package, thus extending shelf life and ensuring food safety.

One of the significant advantages of ready to eat food is the time it saves.

ready to eat pouches helpful for victims of disaster zone, Traveller Army, Air force and navy soldier which cannot be able to cook food.

retort pouch And its Function

1st layer- Polyester Provide good Strength And Toughness

2nd Layer-Aluminum Foil Aluminum Foil provide good barrier properties against oxygen, Light, moisture Vapor.

3rd Layer-Nylon Increases Durability of pouch

4th Layer-Polypropylene Good heat Sealing Properties

These are the Fore layer Of retort pouch

Retort Processing Extends the Shelf life of food product by eliminating microorganisms that can lead to spoilage. This allows for Longterm storage of item like canned goods and ready to eat meals.

Video is showing of Method and Process of retort food packaging and Use retort machinery in Food Industry.

Commercialization machinery for Retort food

Methodology:

This is a standard procedure and equipment’s used for Retort Packaging of food product but in Vigyan ashram these technologies are not available. We were doing it for small scale retort trial, it is not affordable to purchase these machineries for small scale trials or small-scale business.

After discussion with Dixit sir and some literature study I was decided that half cooked rice should be used for retort packaging.

I took the first trial on pressure cooker. But it got failed because the pouches which was used for packing was busted in cooker during sterilization.

After the discussion with Mr. Ranjit Shanbag sir, we decided that we will use small-scale Autoclave for sterilization of food product which is available in Ashram’s microbiology lab.

Autoclave

- Scale on Autoclave:

- psi- Pound-force per square inch A force of one pound-force is applied to a one-square-inch area

- kPS- Kilopascal unit of pressure used to measure internal pressure

- Degree Celsius – Temperature unit

01/09/2023

1st Trial

Jeera Rice

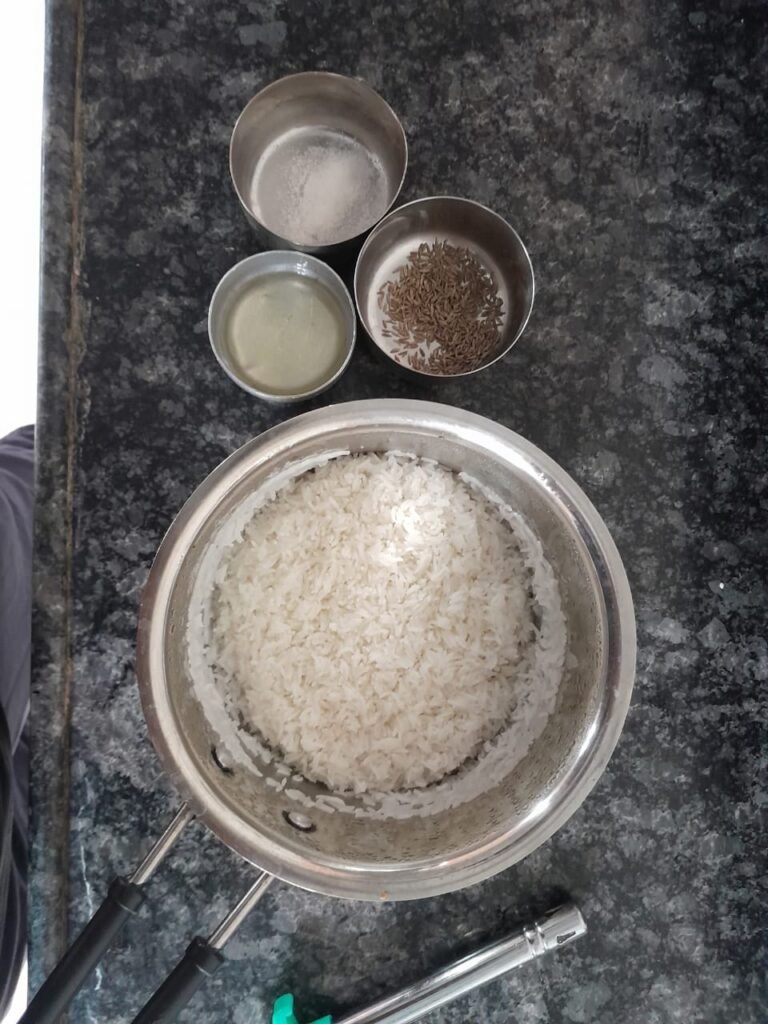

Ingredients

rice-100g

Water-200g

Oil-10g

Jira-3g

Salt- 2g

Procedure:

- 100g Rice washing

- 100g rice + 100g water Soaking for half an hour

- 8 min For cooking Rice+200g water (Salt used)

- Drain extra water

- After cooking rice weight-307g

- Frying in pan Frist oil then Jeera then Cooked rice

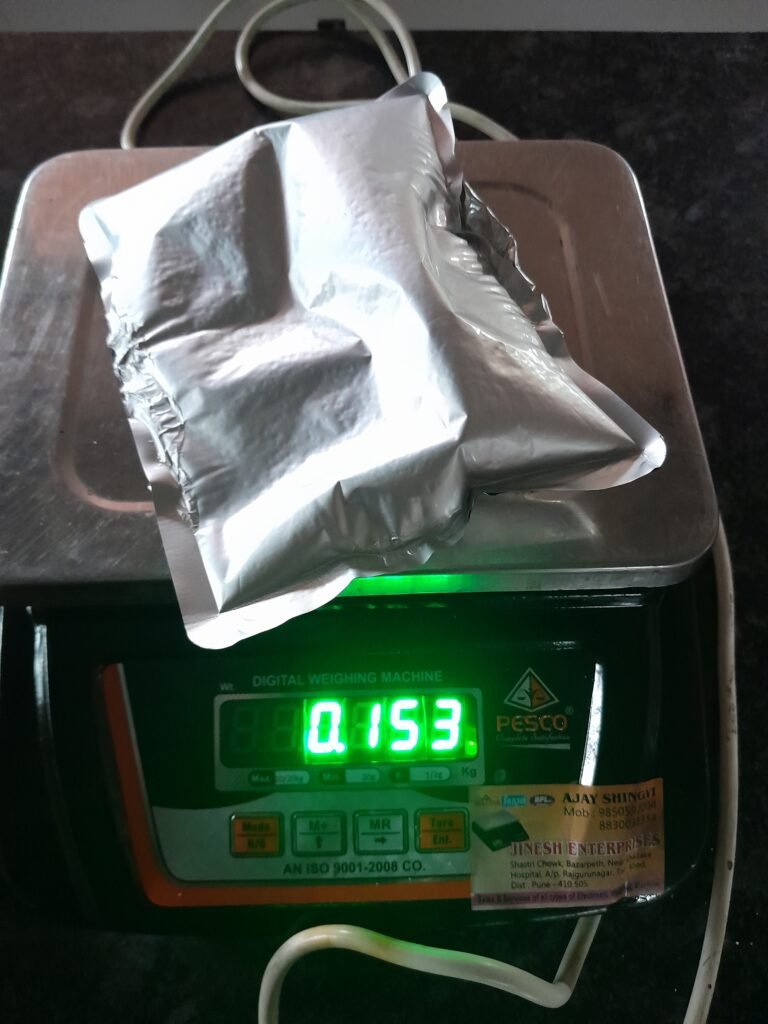

- Two pouches are made 1st 157g and 2nd 153g

- Sealing

- Both pouches put into the autoclave for 45 minutes.

Observation: Both pouches are leak because of improper sealing..

23/09/2023

Ingredients

rice-100g

Water-200g

Oil-10g

Jira-3g

Salt-2g

Procedure

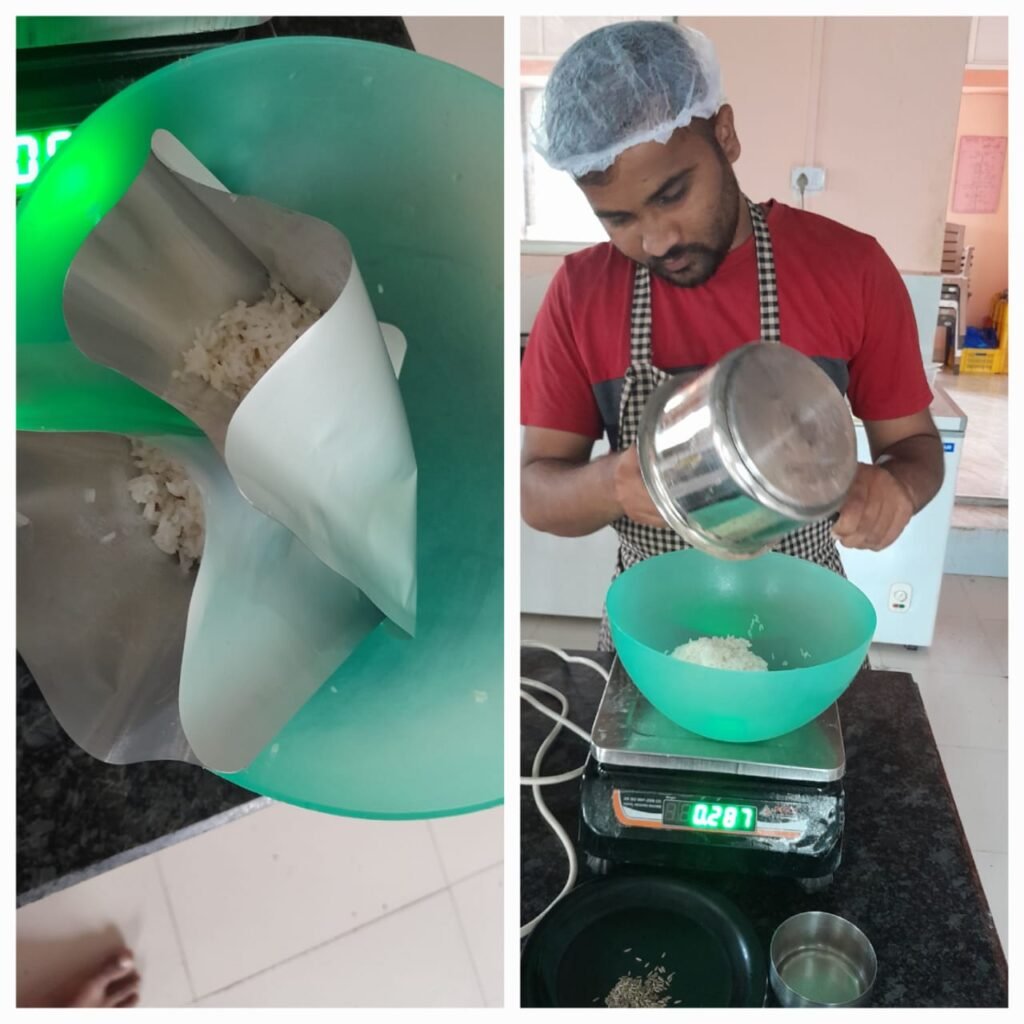

(My friend Shubham also helped me in preparing the recipe.)

Half hr. Soaking Time

Washing Rice(2 time)

5 to 8min Cooking (Water + Soaked Rice)

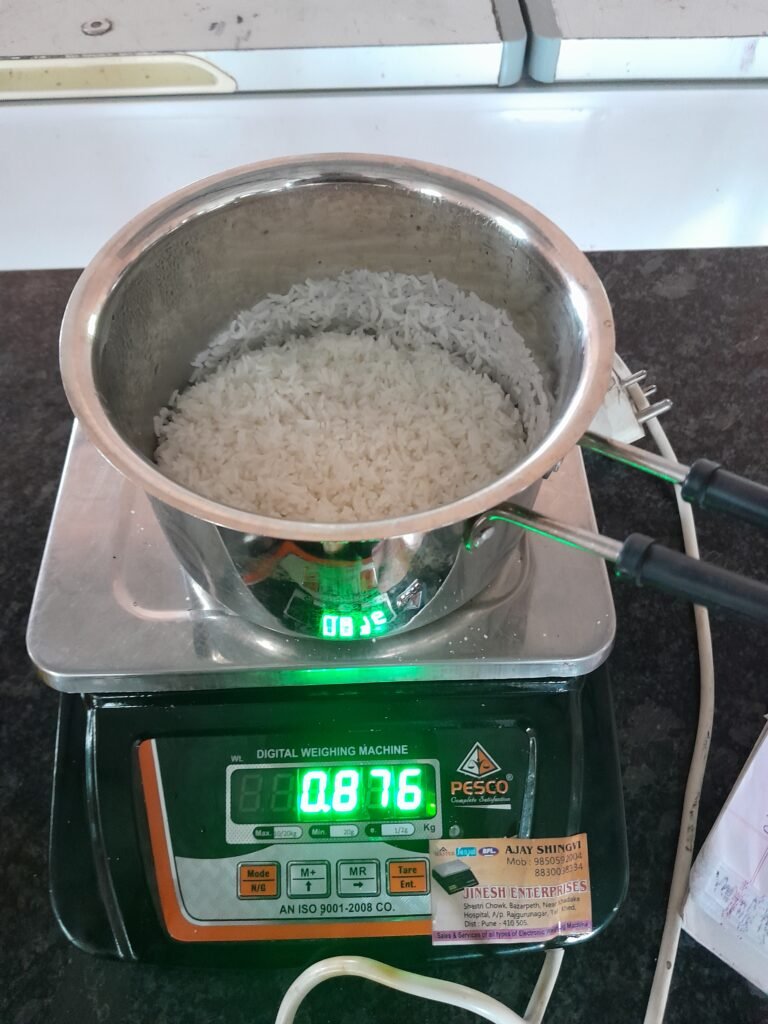

After cooking Weight of rice 311g

Made Half cooked (Sensory Analysis)

Heat Oil in the pan.

Add Cumin seeds and fry them.

Put half cooked rice in the pan and fry for 2 min.

After that, I prepared two packets, with one containing 151 grams and the other containing 155 grams of Jeera Rice

I placed the 1st(155g) Packet in the Autoclave.

&

2nd (151) packet into the Cooker

Time1:58 to 2:38 for 40min

Temperature=110 to 120 Degree Celsius

I immediately turned off the autoclave’s power supply and released the pressure. Within five minutes, the autoclave’s temperature dropped below 100 degrees.

2nd pouch placed into the cooker for 13 min Time 2:05pm to 2:18pm

Steam rice Other Ingredients

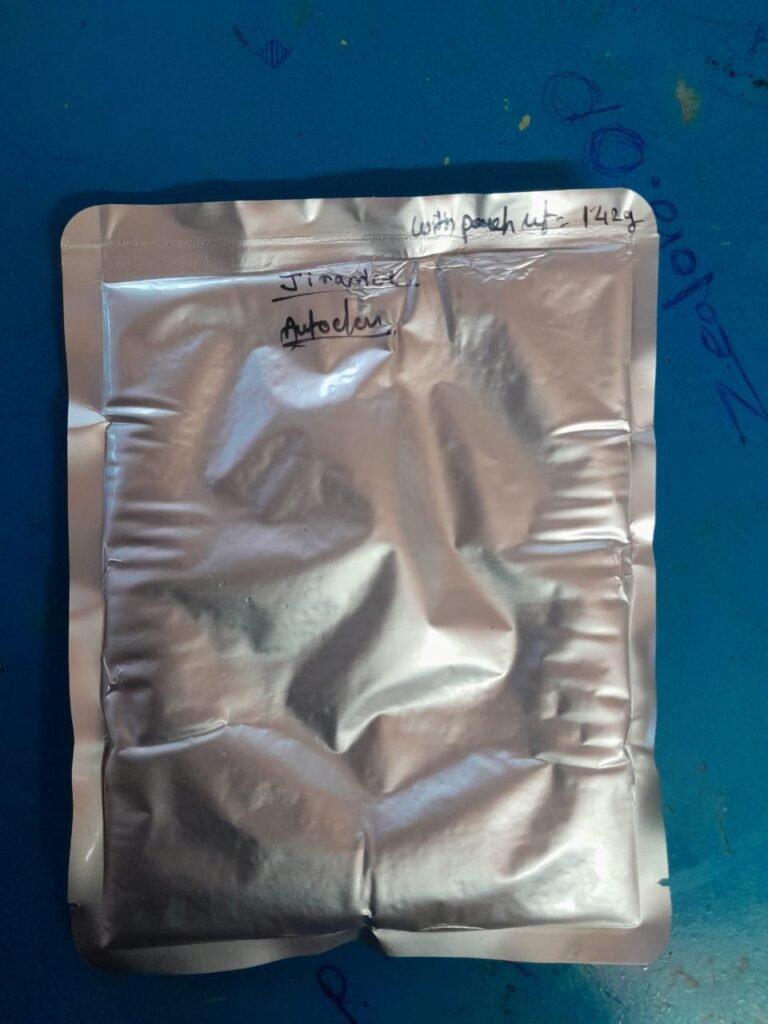

Fig; Leakage Pouch (Upper Lid and Side) and shrinkage of pouch

Observation: (both Pouches)

Pressure built up inside the pouch leading to a leak the pouch and shrink the material of pouch which affect on its look

Leakage Pouch (Upper Lid and Side)

After Discussion With Dixit Sir

The temperature should not be abruptly increased or decreased, and pressure release is not required when the power supply is turned off.

And main problem is sealing machine coil length is 1.6mm that’s why sealing is not suitable for this temperature.

In the next batch, I followed the same procedure and maintained the temperature of Autoclave at 120 degrees. I sealed the packets five to six times using a sealing machine.

In this procedure, I did not release the pressure until the timing of the autoclave was completed, and then I turned off the pressure.

Observation: the Result of 5-to-6-times sealing was Less leakage of pouch than first trial.

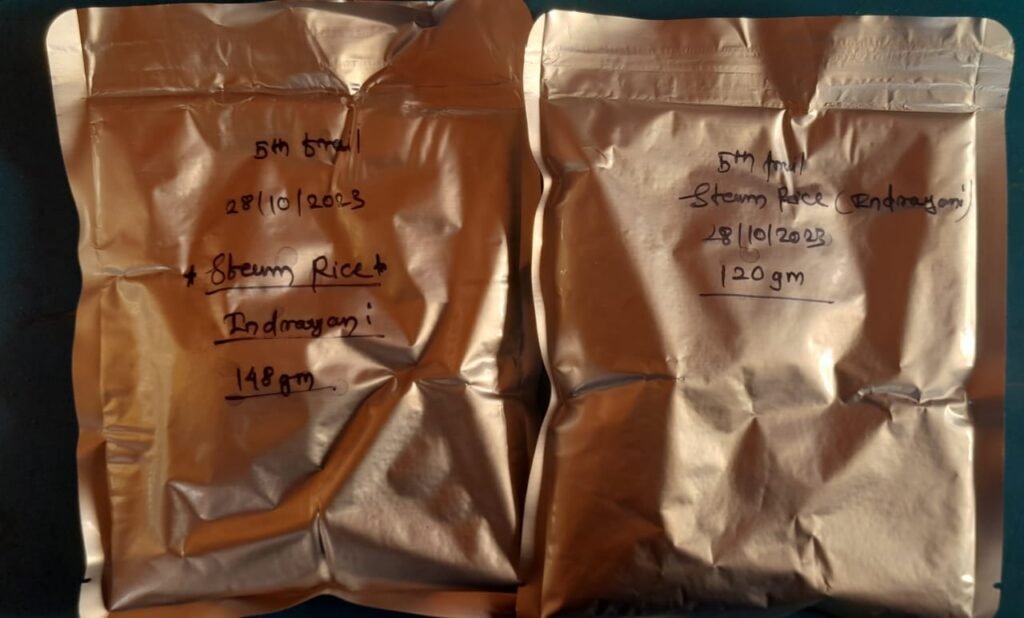

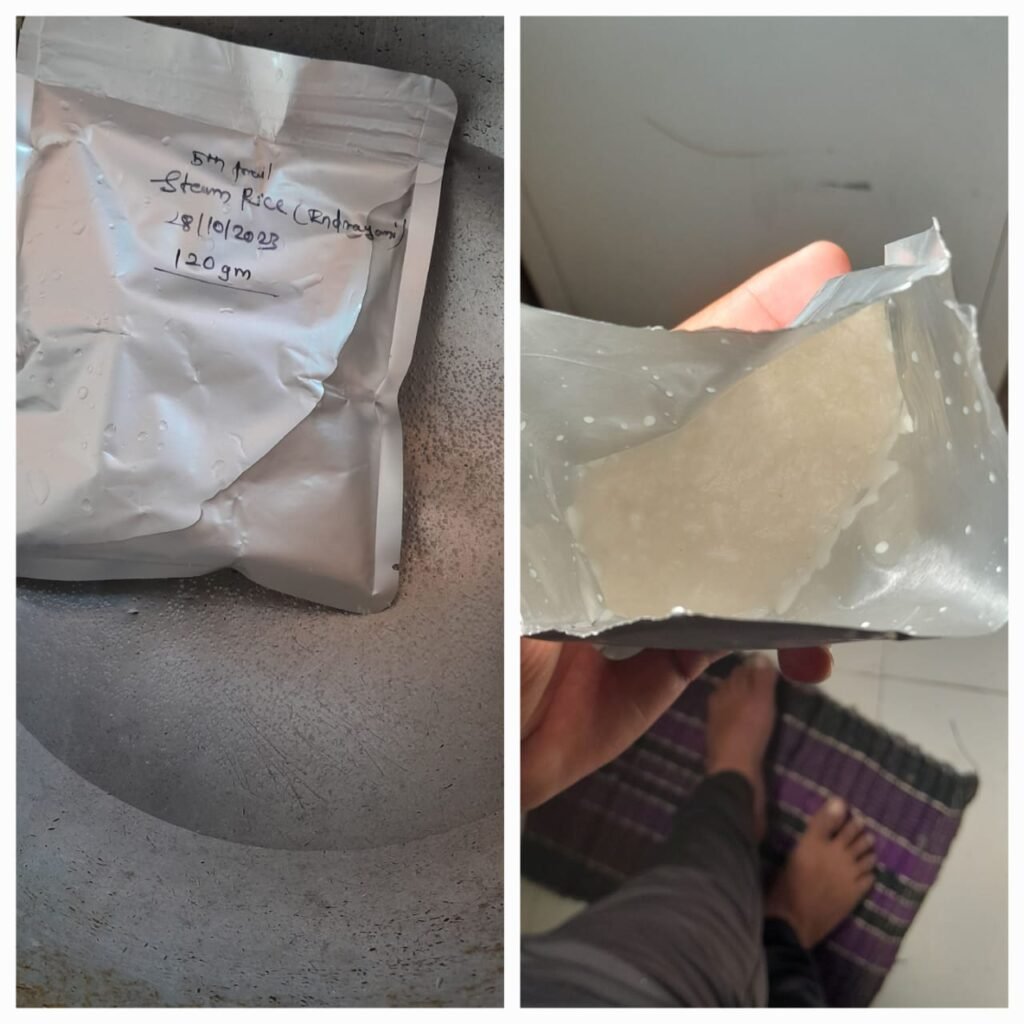

28/10/2023

Indrayani Steam rice

Rice-100g

Salt-2g

Oil-5g

I followed the same procedure like as Washing, Soaking, cooking, Frying, retorting but and maintained the temperature of Autoclave at 120 degrees. I sealed the packets 7 to 8 times using a sealing machine. But this procedure does not use jeera only steam rice.

After Pouch 6 to7 times sealing pouch Doesn’t look Attractive

03/12/2023

Observation:

On opening the pouch dated October 28 after one month and five days, sensory analysis showed no microbial growth but was overcooked and the water content had increased and the Steam Rice in pouch had become semi-solid.

I purchased New sealing machine for retort packaging With Permission of Ranjeet sir

Brand Name: Sepack This machine 1.5 cm Lenth of heating coil

Price:3328 With GST

POWER:180W

Model:200HH

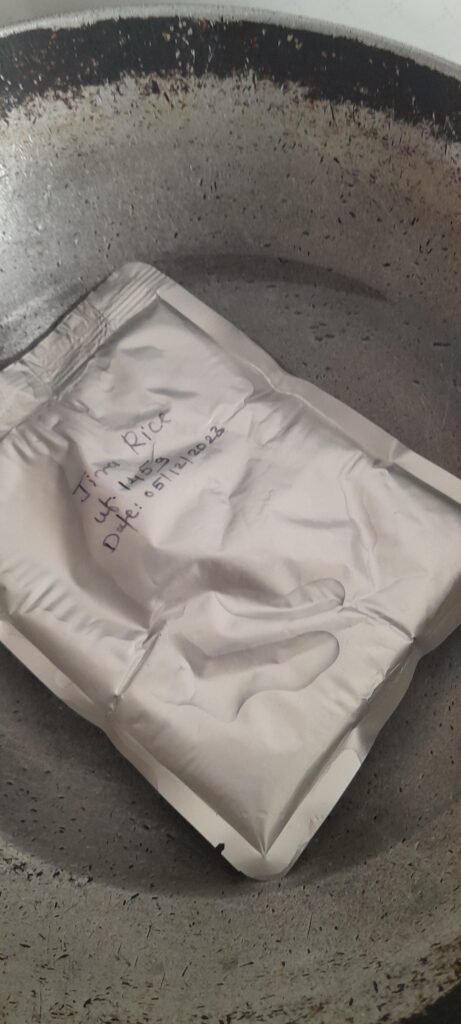

05/12/2023

Jeera rice

Ingredients:

Rice – 100g

Water – 200g

Oil- 7g

jeera-2g

Salt- 3g

Procedure

Take a Rice – 100g & Water – 200g Soaking For 1/2 hr.

Soaking is carried out for decreasing the cooking time. (Boiling time)

After Soaking

Boiling of soaked Rice up to half cook (Sensory Analysis) Cooking Time: 6min. This time add salt

Rice weight-261g

Take a Oil and frying jeera then put a half cooked Rice

Frying for 2 to 3 min.

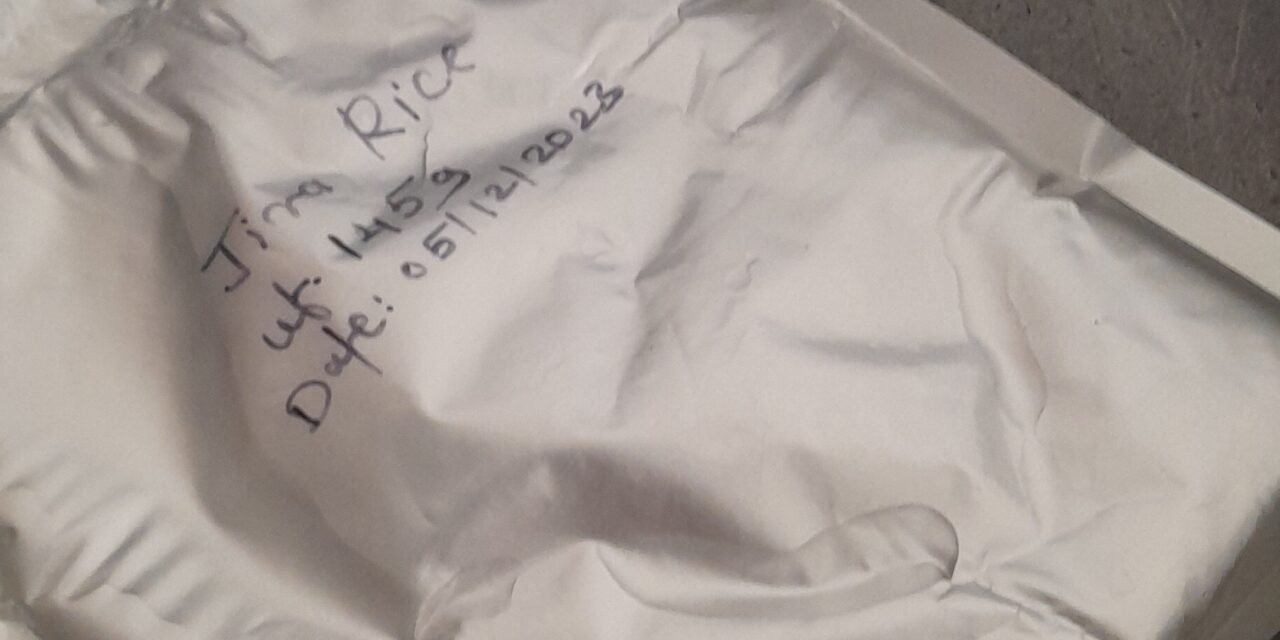

Two Pouch Filling 1Pouch Weight-145g

2nd Pouch Weight-110g

Final Weight of rice-241g

Autoclave 45min

Autoclave requires an half hr. to reach 100 degree and 15min Stable for 116 degree. pressure nob closed

Cooling 30 min After Removing Pouch.

Stable for 15 min Temperature at 116 degrees.

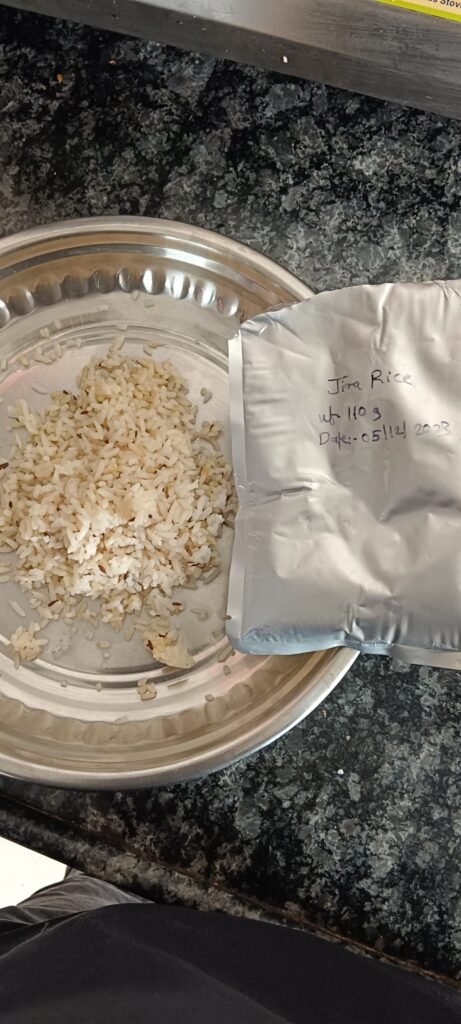

30/12/2023

145g pouch

When you want to test (sensory analysis) the retort pouch first put it in hot water for 5 to 10 minutes then open the pouch and serve it.

Observation:

On the sensory analysis of second pouch of retort jeera rice, It is observed that the retorted jeera rice which un-pouch almost 1-month ages had good in test good jeera flavor and no microbial spoilage.

30/01/2024

Sensory analysis

Observation:

On the sensory analysis of second pouch of retort jeera rice, It is observed that the retorted jeera rice which un-pouch 2 month ages had good in test good jeera flavor and no microbial spoilage.

Conclusion:

On 5th December I was Conducted last trial on Jeera Rice retort. I was took 100gm Rice for cooking, after cooking it was prepared 241gm, then I was packed it in 2 pouches. These two pouches were autoclave it in 2 pouches were autoclave for 45 min at 116 Degree Celsius & kept stable temperature for 15min.

I was Un pouch the first packet on 31st December & performed the sensory analysis.

The jeera rice in first pouch was good in test, and had good jeera flavor and no microbial spoilage. From sensory analysis it was acceptable and its overall acceptability was good.

Then i was used second pouch for sensory analysis on 30th Jan 2024.

On the sensory analysis of second pouch of retort jeera rice, It is observed that the retorted jeera rice which un-pouch 2 month ages had good in test good jeera flavor and no microbial spoilage.

From above trails and observation, it was conducted that, retort jeera rice having minimum almost 2 month shelf life with as it is taste, flavour, texture.