25/02/2023

sangola village ( solapur ) to Adv.B .P. Misal contacted Vigyan Ashram regarding the problem they were facing to dry Drumsticks leaves & vegetable leaves. He wanted Solar Dryer Multi-Purpose Solar Tunnel Dryer in which he could dry all types of leaves & vegetable leaves. For this he came to Vigyan Ashram and Mahesh Sir gave him complete information about the dryer. And he told his demand that what kind of dryer he wanted. After this I took the responsibility of doing this project. Dixit sir guided me.

customer Requirement is Per day drumstick leaves need to be dry up to quantity of 50KG. Customer arrays length 30 feet height 8 feet and width 15 feet= Total surface area 450 Square feet.

To Collect all information for Dryer.

What is Dryer?

A dryer is a machine or device that is used to remove moisture. Any type of material / object can be dried easily by using a dryer. It is of different types. We can use dryer according to the need.

What is drying

Drying is a process that uses heat to remove water (moisture) from a material. This can be done in a number of ways, when water is removed from a substance, its structure changes. This process makes the material harder and less prone to spoilage. This process eliminates the problem of growth of bacteria, yeast and other moisture-related microorganisms in food products. So that the material does not get spoiled for a long time.

The drying rate depends on the material, the humidity and temperature of the surrounding air. In general, the higher the temperature and the lower the humidity, the faster the drying process. Drying is the process of removing excess water keeping in mind the nutritive value, speed visibility and further use. Through this process, food products like pickles, chilies, amla, fish, fruits and spices can be used for a long time after drying.

different Types Of dryers

•

1. Integrated Solar Dryers: In this type, solar energy collection and drying takes place in a single unit. Some examples of this category include step type dryers, cabinet dryers, rack dryers, tunnel dryers, greenhouse dryers and multi-rack dryers.

2. Distributed Solar Dryers: In this type, solar energy collection and drying takes place in two separate units, namely a flat plate air-heater and a drying chamber. Flat plate heaters can be placed on the roof of a building or on the ground or in a place where the intensity of the sun is high. In flat plate heater the air is heated and with the help of blower the hot air is circulated to the drying chamber of the dryer.

3. Mixed Mode dryer: In this type, the solar energy collection takes place in both the flat plate air heater as well as the drying chamber and drying takes place only in the drying chamber. The exterior of the dryer will also receive solar power; It helps to remove moisture quickly.

Solar tunnel dryer:- Tunnel dryer is a semi-cylindrical tunnel shaped dryer. The frame of the dryer is made of galvanized iron and covered with a 200 micron size ultraviolet (UV) stabilized polyethylene sheet, which retains heat inside the dryer. While the inlets at the rear end of the dryer allow fresh air to enter the dryer, the exhaust fan on its front expels moist air from the product. This type of dryer is used for drying sago, coconut, chilli, amla, onion, vegetables, fruits and other agricultural products.

1. According to Sabudana, the drying time in solar tunnel dryer is 5 hours, while the drying time in open sunlight is 11 hours. Thus, about 55% of the drying time is saved in solar tunnel dryers.

2. It takes 43-45 hours to dry one ton of chilli whereas 70 hours is required for drying in the open sun. Using this dryer for drying Byadgi chillies showed a saving of about 40-60 per cent in drying time

Merits Of Dryers

- Higher drying temperatures.

- Offers airflow and temperature control.

- Food is protected from elements.

- Any material can be dried in a short time with high temperature and air movement in the chamber.

- Time Saving |

- Dryers can be manufactured from locally available materials at relatively low cost.

- Solar dryers last longer. A typical dryer can last for 15-20 years and will require minimal maintenance.

- It needs a small area.

- The dryers are also waterproof, so there is no need to move food in rainy weather.

- There is less risk of damage to food products.

- Solar dryer keeps food products safe from dust, insects, birds and animals.

- Fast drying.

- The high temperature prevents insect infestation and the rapid drying rate reduces the risk of spoilage by microorganisms.

Demerits Of Dryers

• It can be used only during day time when solar energy is present in sufficient quantity.

• Must have skilled personnel for operation and maintenance.

• Takes longer than modern types of electric dryers.

Solar dryer can be used more during sunny days only.

• A backup heating system is essential for products requiring continuous drying.

• The cost of some dryers is high. Due to which small farmers and needy people cannot buy them.

• Requires large amount of initial investment.

• Requires collaboration cost

• Solar dryers can be slower to process than dryers that use conventional fuel.

• Generally, solar dryers can be used to dry materials at 40-50oC.

Drying methods

The natural drying process is usually done using direct sunlight, that is, the sun’s rays hit the product and remove its moisture through natural air circulation. This method is a slow process and has some disadvantages such as dust contamination, insect infestation, and spoilage due to unpredictable rains. These problems can be eliminated by using the mechanized method of drying.

Solar Dryer: – Solar dryer is good other way of drying and it is environment friendly. Any type of material can be dried quickly in a solar dryer. Solar dryers help to provide more heat than the atmospheric temperature. The air in the solar dryer enters the solar dryer through the process of a natural chamber or from an external source such as a fan and the air is heated to the temperature of the dryer along with the moisture and is expelled through the exhaust fan or chimney. This process continues due to which the material dries up. In operation, these dryers can produce temperatures of 54 to 82 °C, which is useful for most food ingredients drying and pasteurization.

Working Of Dryer

Solar dryer receives the energy from sun and it dry the crops vegetable fruit

Solar dryer consists with different main parts

Black material is coated on heating element inside the box to absorb more heat from solar radiation . outer frame of made up of heat insulating material to maintain the temperature .when direct or diffuse solar radiation will incident then it will not exit .

There are holes at upper and lower portion of the box for circulation of air .

First of all we keep the fooding material inside the box and close the roof glass

When solar radiation incident on black coating through transparent glass then heating aliment absorb the heat from solar radiation due to heat moisture of fooding material get vaporized and vapor droplets accumulates on the roof glass

As well as cold air enter from lower portion of the box and that air get heated

Due to hot air fooding material rapidly get dry and heated air exit thought upper hole

Vaporized water droplets also remove with hot air in the atmosphere and placed fooding material like vegetables get dry

27/02/2022

Dixit sir and Mahesh and all of us discussed how to build the dryer in this.

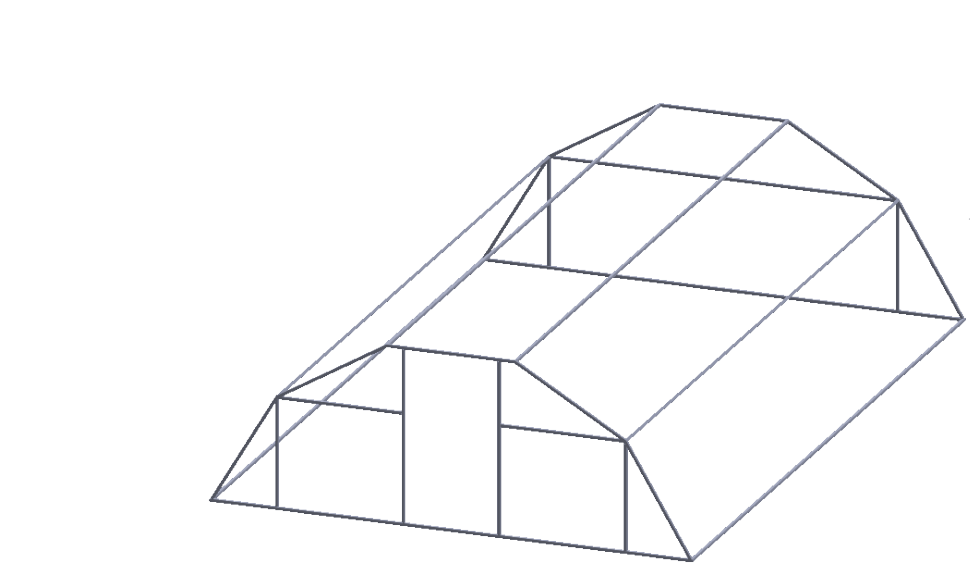

discussion we considered different shapes basically three shapes first half round tunnel dryer second dome dry and third pentagon tunnel dryer.

Basically three shapes are considered.

1).half round tunnel dryer

2). dome dryer

3).pentagonal Tunnel dryer.

At the same time we started this calculations ( Find outs Area, Working space, height, width & all parameters & BOM) we see how Air circulations can be done in it, we can see that two types of air circulations can be done,

- Natural Air circulations

- Forced Air circulation

- Natural air circulation- Air Passes through The naturally Input & Output port through

- Forced Air circulations – Installed Two different types of fan one is creation of vacuumed fans & anther is Exhaust fan

But first we thought of without fans i.e. natural convection air circulation as it was the client’s requirement then we started working on it.

28/02/2023

We did some experiments

- we calculate ho match area we require for drying 50kg leaves

First we calculated how much area is required to Dray 50 kg of leaves, for that we did an experiment, we took 100 grams of leaves, then spread it on a flat surface in a thin layer. Then when the ratio was taken as per our requirement, the area was 555 square feet for 50 kg.

how to, they as follows

100gm leaves to required area 1.11sqft

50kg leaves to required area 555 sq ft

so we get 1.11 sq ft so we get total we require is 555 sq ft for dyeing 50 kg of drum steak leaves

We Taking A Area.

Again we studied the shape one by one as we thought about the shape.

First we studied the half round tunnel dryer as per Misal's requirement, in which we need 555 square feet of space to dry the leaf, so we Assume that its height, width, length height 8.5 feet width 17 feet length 30 feet

calculations, i.e. bill of material surface area. As follows length thirty feet height eight feet various 17 feet and its total area is 510 square feet. As we start designing it, we see how many layers we have to do to dry that layer, then as the half circular tunnel dryer goes to the top layer, we get less area, if we decide to do five layers, then its calculations and area are as follows

calculate how many layer we build according our area

totaled 5 layer=area 567 sq ft

each layer width

1 layer=7.5 ft

2 layer=7 ft

3 layer=6.25 ft

4 layer=5.50 ft

5 layer=4.75 ft

We getting total operational area 567sq ft.

1/03/2023

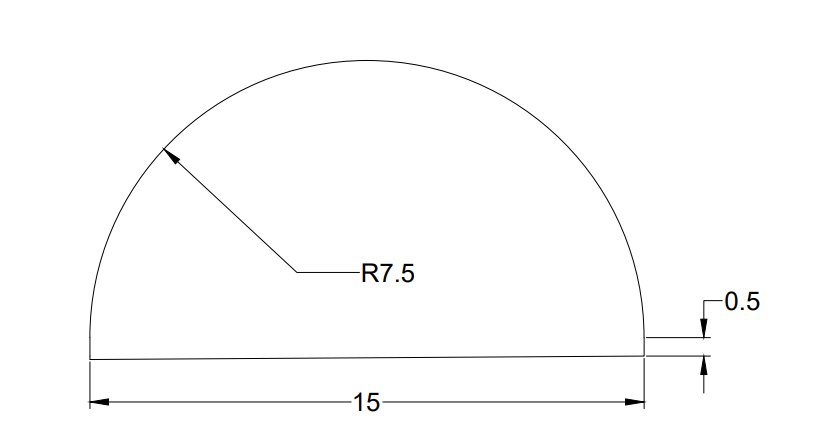

We had a discussion once again in that discussion we once again thought about size and shape and discussed about different dryers. What we had designed did not match Misal's measurements so we thought that we would try the calculation as per Misal's measurements and we noticed that if we keep the width as stated by Misal, we get less height, only we get half a foot less height. On that we thought that we should fix the tunnel dryer by taking the foundation half a foot from the base and placing this floor on it and started the next work accordingly.

we modify as follow

1)in we increase foundations Hight 0.5 ft

2) for doing customer satisfaction the given dimension

we redesign 1/2 round tunnel dryer in that we changed

1) ground clearance 0.5 ft foundation on that 7.5 ft radius tunnel dryer we fitted on that

The corresponding bill of material size is designed back as follows

Design Of Half Round Tunnel Dryer

02/03/2023

After that we have done some market survey and the market is as follows

Market Survey

On this market survey I gave a presentation in front of Dixit, Prasad & mahesh Sir and all DIC fellows.

In this market survey we found that. 1). The cost of all was going up to approximately one and a half to two lakhs 2). All the tunnel dryers available are half round tunnel dryers and main ones are polythene used dryers. After that we had a discussion again and in the discussion a new point was realized that polycarbonate sheet is more efficient than polythene sheet. We started thinking about polycarbonate sheets We noticed that the polycarbonate seat does not bend but cracks immediately under tension. So in our discussion it was thought to change the cross section of the tunnel dryer. We were also thinking about a similar Dom Dryer because his subject is the most exposed to sun exposure, his body is in an aerodynamic shape and we thought this is rate lower coast and we researched that as well. A study was made on the determined dryer and some calculations were made.

03/03/2023

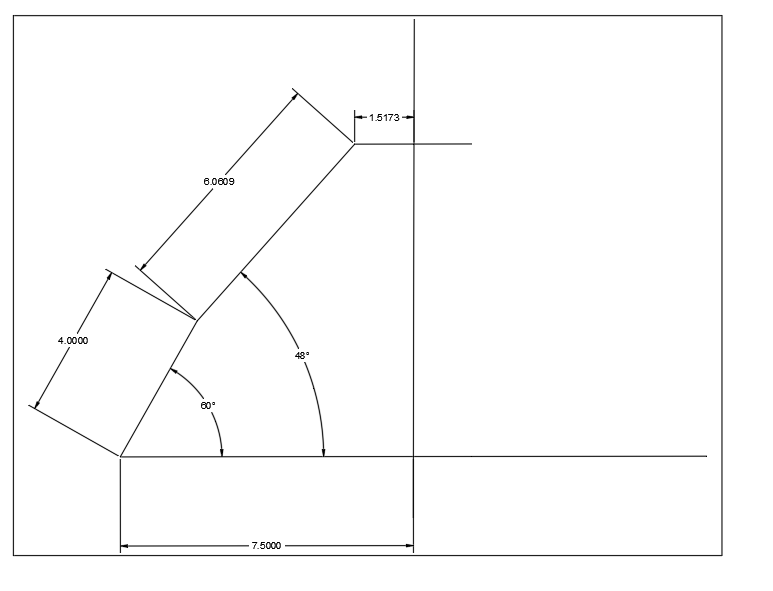

we Started studing pentagon tunnel dryer, Took out its bill of materials, Decided how much height how much height to keep, what width To keep top surface and its rough drawing is as below. and we will design

Design Of pentagon tunnel dryer.

then I explain this all terms of pentagon tunnel dryer

Upper layer 3 feet

side wall 7.2 feet

height 4 ft

width 15 ft

length 30 ft

in this we get more sun exposer more than the above design in this structure top side increase the flat surface according to that we design further so we get dimension as show in fig

.upper flat surface 3 ft ground width 15 ft side wall 4 ft angular surface 6 ft

Bill Of material

Once again we had a discussion, in that discussion, whatever wall was formed, the sun rays did not fall at all, that is, if the sun is in the east in the morning, it will cover the same area, and if it is high in the afternoon, it will cover only the upper area & evening, if it moves to the west, its will cover its site. if the part will cover

this is in a Discussion presents in a mahesh, prasad sir & dixit sir, We realized that we don’t get these sunrises continuously, so our turn quickly. then we thought about how to get the most sunrises.

We had a lot of trouble in these calculations because we were not getting the height as per sir’s requirement, something was getting reduced due to changing the angle or else the width of the upper layer was getting reduced so we made one constant which is the walls of the polycarbonate sheet we get. Keep the width the same. So we got two angles and keeping the height same and first we got two angles which were 36 degrees and 71 degrees

we check different different angle using

if we put this angle to our structure then two cases are happen fast reduction of height and another is the top surface width is 4ft

as follows

Angles Photos

we check reducing a height .

04/03/2023

Also, if we consider the polycarbonate sheets available in the market, there are two types of sheets available in the market,

- 4X39 feet

- 7X99 feet

We did not consider that in the calculations of the tunnel dryer. In this discussion, we looked at how the dryer can be made with minimum material i.e. without waste of material. It was decided that each wall should be four feet, so we started working on it

we selecting a sheet 4X39 feet sheet.

We had a lot of trouble in these calculations because we were not getting the height as per Sir’s requirement, something was getting reduced due to changing the angle or else the width of the upper layer was getting reduced so we kept one should constant.

1). The width of the polycarbonate is kept the constant

2). The angles of walls are also constant

we decided to put angle 30-60-90

Again in this discussion, a new thing was considered that first we were going to take 6″ foundation from the bottom for the half round tunnel dryer that we were thinking about, then we decided that we would take the height and fix two angles and the width of the wall. decided

We decided to let the height come, let us take that height and decide to fix two angles and the width of the wall, we took two angles 30 60 90 and width four feet, we got the height five and a half feet. It was suggested to take a foot or two foot foundation from the bottom and we thought that the dryer can be installed on that too

So we got a height of 5.5 feet which was too small so we suggested them to get a 1or 2 foot foundation from below and we thought we can install the dryer on it too. The our design was temporarily finalized because

We had not given up thinking about Dom, we were still studying Dom

06/03/2023

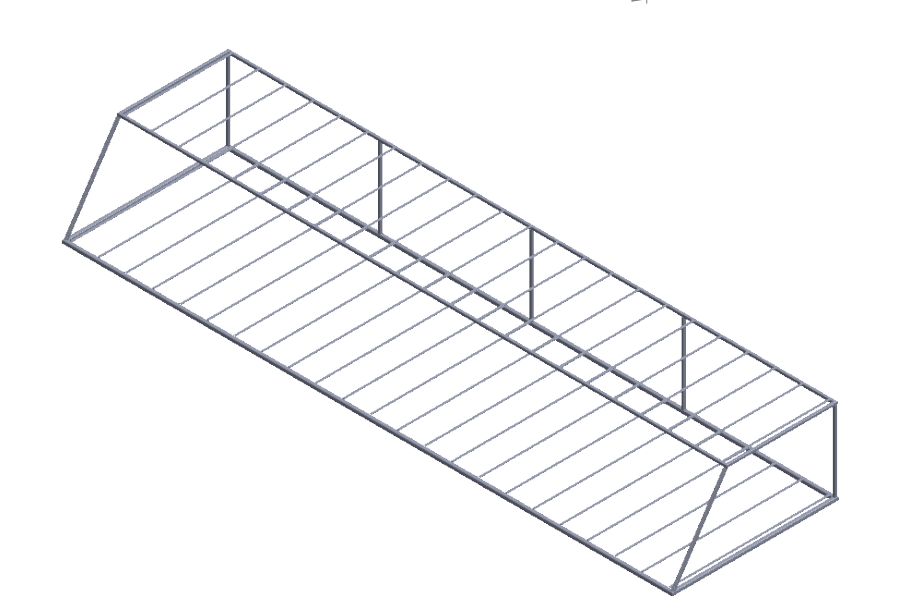

Then we started to draw its BOM, how will its trays be, how will it be used, its size working area, how will it be easy to handle and cost, we started the work

How much to leave the working area, how much to keep the size of the tread, how much to trek, how much to clear the tray structure.

results are as follows

first we decided to do layers because our Area is sufficient.

1. And we decided the height between those two layers to be three feet because even if a person is standing, we kept the height of the second layer to be three feet, and the height of the first layer was kept to the ground level, because the foundation would be two or one feet below. So we decided to make the first layer at the bottom and the second layer at a distance of three feet from the first layer as per the design of our tunnel dryer and the total is 15 feet. 2. The second point is why we left only three feet of working space because we decided to keep the maximum working space for the main reason that people should be able to walk easily and the trays that we are going to take out should come out easily. 3. The size of the tray rack is six feet wide, so the first layer is three by two and a half trays, and since the total width is six feet, two three-foot trays will fit together and it will not be a problem for you to take out the trays because you have a working space of three feet. Since we finalized the size of the tray as 3 by 2.5 and since the second layer is angled we did not get the total width of 6 feet, so we decided to tray 2.5 by 2.5.

Material also considered, two types of BOMs were drawn, one in MS and the other in GI, with Rough. quotations Quotation's Excel sheet

07/03/2024

At the same time, we were thinking of Dom dryers and we took the bill of materials. We decided that the cost would be reduced, but there is a lot of wastage of polycarbonate and its structure is a little hard, so the costing is high. The bill of materials is as follows.

13/03/2023

We have basically considered and studied these three shapes and prepared the Bill of Material by comparing different shapes and create BOM.

Another requirement to be added was that since they were our previous clients, they had previously purchased a Flat Flat Solar Dryer from us which cost ten thousand. So their requirement was tunnel dryers requirement for drying to 50kg leaves

But they were going to pay the same cost, they said that if the cost of tunnel Dryers increases, then we will buy ten such flat plate dryers.

14/03/2023

before talking to misal, we had a discussion, prasad sir, mahesh sir & dixit sir and Compared one again. Tunnel, dome & flat

all data fill here

So we discussed another new design

So we realized that it takes two days to dry five kg of leaves in a flat plate dryer, so misal needed ten flat plate dryers to dry 50kg leaves

When we calculated it, we realized that Misal would need 19 dryers instead of 10 dryers

I give the Presentation on Tunnel Dryer in front of Adv. Misal sir & dixit sir & mahesh Sir.

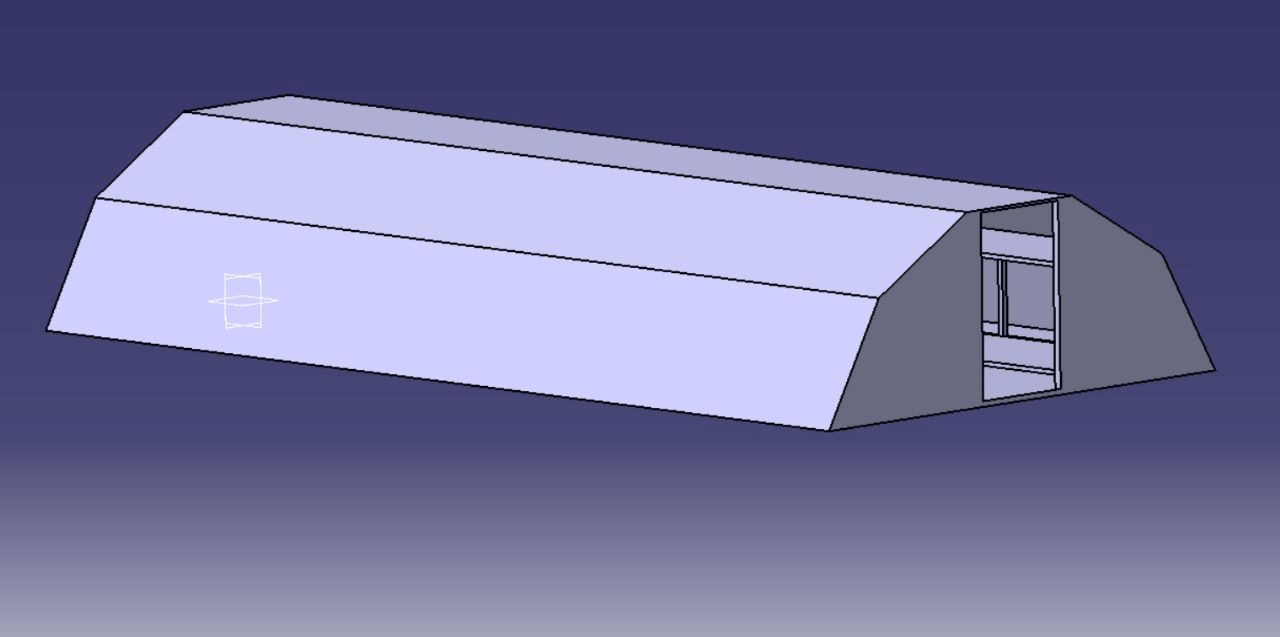

I create The Actual Design modeling of tunnel dryer with help of Solid works software.

we find out the all Dimensions of tunnel dryer & design it.

we fist Design.

all parts Drawings of tunnel dryer.

1 Tray

- Tray 1 Sizes 862mmX914mmX 25.00mm

- Tray 2 Sizes 550mmX911.39mm X25.00mm

2 Tray Structure

lenghth 6700mm

width 1840mm

height 914.40mm

3 Tunnel Structure

length = 6858.00mm

height = 1664.35mm

width = 4572mm

Final BOM

our project is stopped because the, Our clients is not Responding’s to me.