sangola village ( splapur ) to Adv.B .P. Misal contacted Vigyan Ashram regarding the problem they were facing to dry Drumsticks leaves & vegetable leaves. He wanted Solar Dryer Multi-Purpose Solar Tunnel Dryer in which he could dry all types of leaves & vegetable leaves. For this he came to Vigyan Ashram and Mahesh Sir gave him complete information about the dryer. And he told his demand that what kind of dryer he wanted. After this I took the responsibility of doing this project. Dixit sir guided me.

customer Requirement is Per day drumstick leaves need to be dry up to quantity of 50KG. Customer arrays length 30 feet height 8 feet and width 15 feet= Total surface area 450 Square feet.

What is Dryer?

A dryer is a machine or device that is used to remove moisture. Any type of material / object can be dried easily by using a dryer. It is of different types. We can use dryer according to the need.

What is drying

Drying is a process that uses heat to remove water (moisture) from a material. This can be done in a number of ways, when water is removed from a substance, its structure changes. This process makes the material harder and less prone to spoilage. This process eliminates the problem of growth of bacteria, yeast and other moisture-related microorganisms in food products. So that the material does not get spoiled for a long time.

The drying rate depends on the material, the humidity and temperature of the surrounding air. In general, the higher the temperature and the lower the humidity, the faster the drying process. Drying is the process of removing excess water keeping in mind the nutritive value, speed visibility and further use. Through this process, food products like pickles, chillies, amla, fish, fruits and spices can be used for a long time after drying.

different Types Of dryers

•

1. Integrated Solar Dryers: In this type, solar energy collection and drying takes place in a single unit. Some examples of this category include step type dryers, cabinet dryers, rack dryers, tunnel dryers, greenhouse dryers and multi-rack dryers.

2. Distributed Solar Dryers: In this type, solar energy collection and drying takes place in two separate units, namely a flat plate air-heater and a drying chamber. Flat plate heaters can be placed on the roof of a building or on the ground or in a place where the intensity of the sun is high. In flat plate heater the air is heated and with the help of blower the hot air is circulated to the drying chamber of the dryer.

3. Mixed Mode dryer: In this type, the solar energy collection takes place in both the flat plate air heater as well as the drying chamber and drying takes place only in the drying chamber. The exterior of the dryer will also receive solar power; It helps to remove moisture quickly.

Solar tunnel dryer:- Tunnel dryer is a semi-cylindrical tunnel shaped dryer. The frame of the dryer is made of galvanized iron and covered with a 200 micron size ultraviolet (UV) stabilized polyethylene sheet, which retains heat inside the dryer. While the inlets at the rear end of the dryer allow fresh air to enter the dryer, the exhaust fan on its front expels moist air from the product. This type of dryer is used for drying sago, coconut, chilli, amla, onion, vegetables, fruits and other agricultural products.

1. According to Sabudana, the drying time in solar tunnel dryer is 5 hours, while the drying time in open sunlight is 11 hours. Thus, about 55% of the drying time is saved in solar tunnel dryers.

2. It takes 43-45 hours to dry one ton of chilli whereas 70 hours is required for drying in the open sun. Using this dryer for drying Byadgi chillies showed a saving of about 40-60 per cent in drying time

Merits Of Dryers

- Higher drying temperatures.

- Offers airflow and temperature control.

- Food is protected from elements.

- Any material can be dried in a short time with high temperature and air movement in the chamber.

- Time Saving |

- Dryers can be manufactured from locally available materials at relatively low cost.

- Solar dryers last longer. A typical dryer can last for 15-20 years and will require minimal maintenance.

- It needs a small area.

- The dryers are also waterproof, so there is no need to move food in rainy weather.

- There is less risk of damage to food products.

- Solar dryer keeps food products safe from dust, insects, birds and animals.

- Fast drying.

- The high temperature prevents insect infestation and the rapid drying rate reduces the risk of spoilage by microorganisms.

Demerits Of Dryers

• It can be used only during day time when solar energy is present in sufficient quantity.

• Must have skilled personnel for operation and maintenance.

• Takes longer than modern types of electric dryers.

Solar dryer can be used more during sunny days only.

• A backup heating system is essential for products requiring continuous drying.

• The cost of some dryers is high. Due to which small farmers and needy people cannot buy them.

• Requires large amount of initial investment.

• Requires collaboration cost

• Solar dryers can be slower to process than dryers that use conventional fuel.

• Generally, solar dryers can be used to dry materials at 40-50oC.

Drying methods

The natural drying process is usually done using direct sunlight, that is, the sun’s rays hit the product and remove its moisture through natural air circulation. This method is a slow process and has some disadvantages such as dust contamination, insect infestation, and spoilage due to unpredictable rains. These problems can be eliminated by using the mechanized method of drying.

Solar Dryer: – Solar dryer is good other way of drying and it is environment friendly. Any type of material can be dried quickly in a solar dryer. Solar dryers help to provide more heat than the atmospheric temperature. The air in the solar dryer enters the solar dryer through the process of a natural chamber or from an external source such as a fan and the air is heated to the temperature of the dryer along with the moisture and is expelled through the exhaust fan or chimney. This process continues due to which the material dries up. In operation, these dryers can produce temperatures of 54 to 82 °C, which is useful for most food ingredients drying and pasteurization.

Working Of Dryer

Solar dryer receives the energy from sun and it dry the crops vegetable fruit

Solar dryer consists with different main parts

Black material is coated on heating element inside the box to absorb more heat from solar radiation . outer frame of made up of heat insulating material to maintain the temperature .when direct or diffuse solar radiation will incident then it will not exit .

There are holes at upper and lower portion of the box for circulation of air .

First of all we keep the fooding material inside the box and close the roof glass

When solar radiation incident on black coating through transparent glass then heating aliment absorb the heat from solar radiation due to heat moisture of fooding material get vaporized and vapor droplets accumulates on the roof glass

As well as cold air enter from lower portion of the box and that air get heated

Due to hot air fooding material rapidly get dry and heated air exit throught upper hole

Vaporized water droplets also remove with hot air in the atmosphere and placed fooding material like vegetables get dry

The Outcome Of Discussion

Discussed with Dixit Sir About Tunnel Dryer.

Problem

Customer Require is Per day drumstick leaves need to be dry up to quantity of 50KG.

Customer arrays length 30 feet height 8 feet and width 15 feet= Total surface area area 450 Square feet.

In this area, tunnel dryer need to be build

Solution

1> Discuss with Dixit Sir about area, Size and shape

2> So it is found that 100 grams 1.11 square feet of space is required, so we need an area of 55.55 square feet to dry the total area.

100gm = 1.1 square ft = 1 plate

1000gm = 11.1 square ft = 10 plate

50 kg = 555 square ft 500 plate

total plate or for leave areas for dry is 555 square ft require.

We get

Discuss with Dikshit Sir, and we get three conclusions in that Dome, Tunnel and hexagonal tunnel.

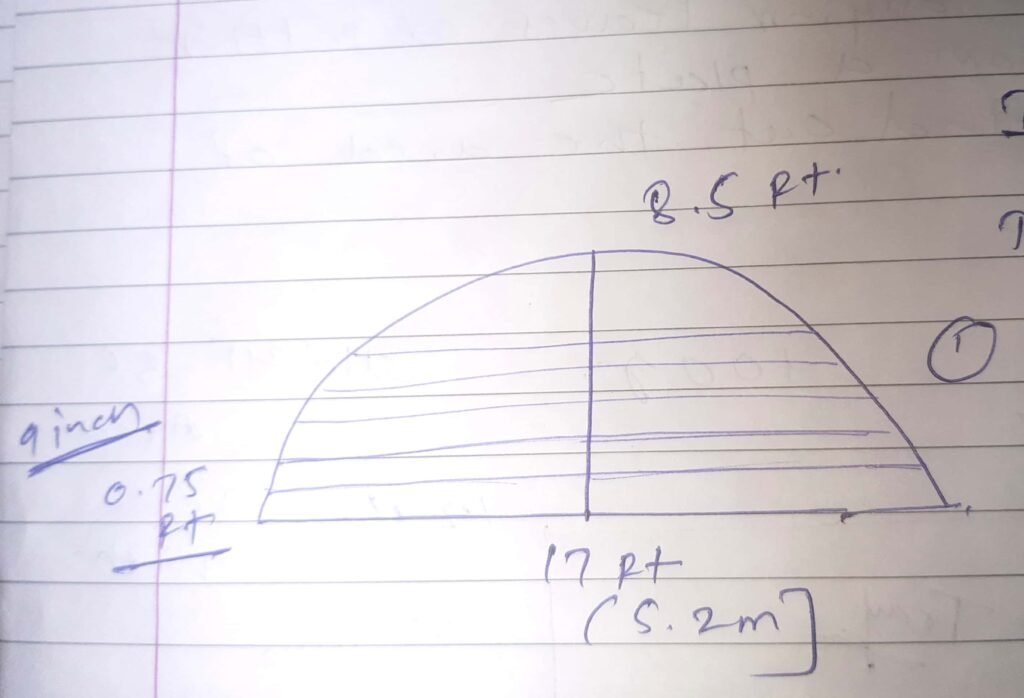

1>First, we calculate Dome design.

dome size h=8.5 ft, radius 8.7 ft.

in that total surface area=226.98 square ft.

in that 5 layer in between difference 0.75 ft distance

1 layer 7.75 radius we get area. 180

2>layer 7 radius we get area 154.

3>layer 6.25 radius we get area 123.

4>layer 5.50 radius we get area. 95

5>layer 4.75 radius we get area. 17

we gate total area=630 square ft

operation area 62.5 square ft

total area for drying porpes 567.5 square ft.

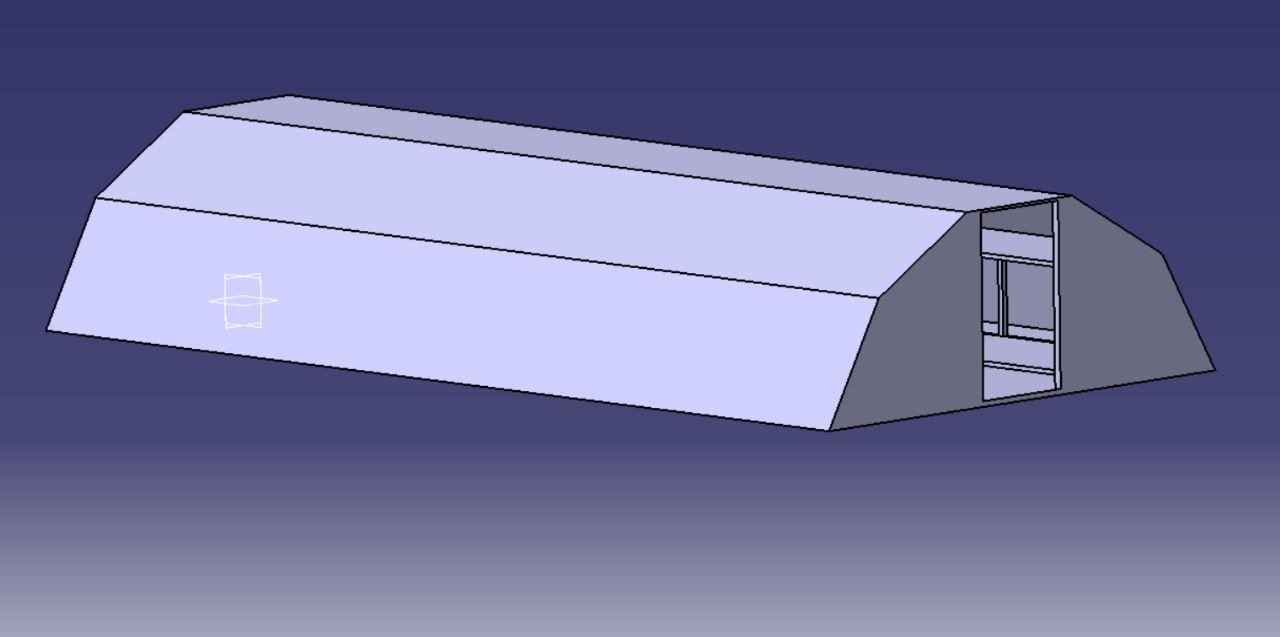

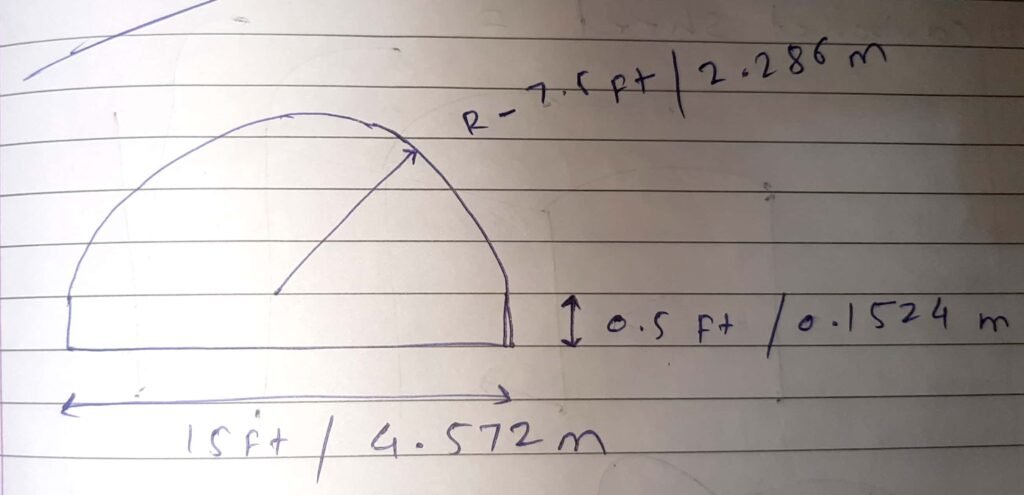

<2> Tunnel dryer circular shape.

Height 8 feet width 15 feet and length 30 feet.

And total area. 450 Square ft.

Tunnel dryer area calculation

Area 450 square ft

In topside polycarbonate sheet is require 731.1

Stop and backside area one. 190.8 square feet.

And we need total area 928.9 Approx 930 square ft Required.

Upper side bend pipes 24.57 feet x10 nos = 245.7 =12.2 pipes are required.

Berlin pipes = 30 feet. X 5 nos= 150ft=7.5 pipe.

Front and backside pipes= total. 74.2 ft= 3.7 pipes are required.

.

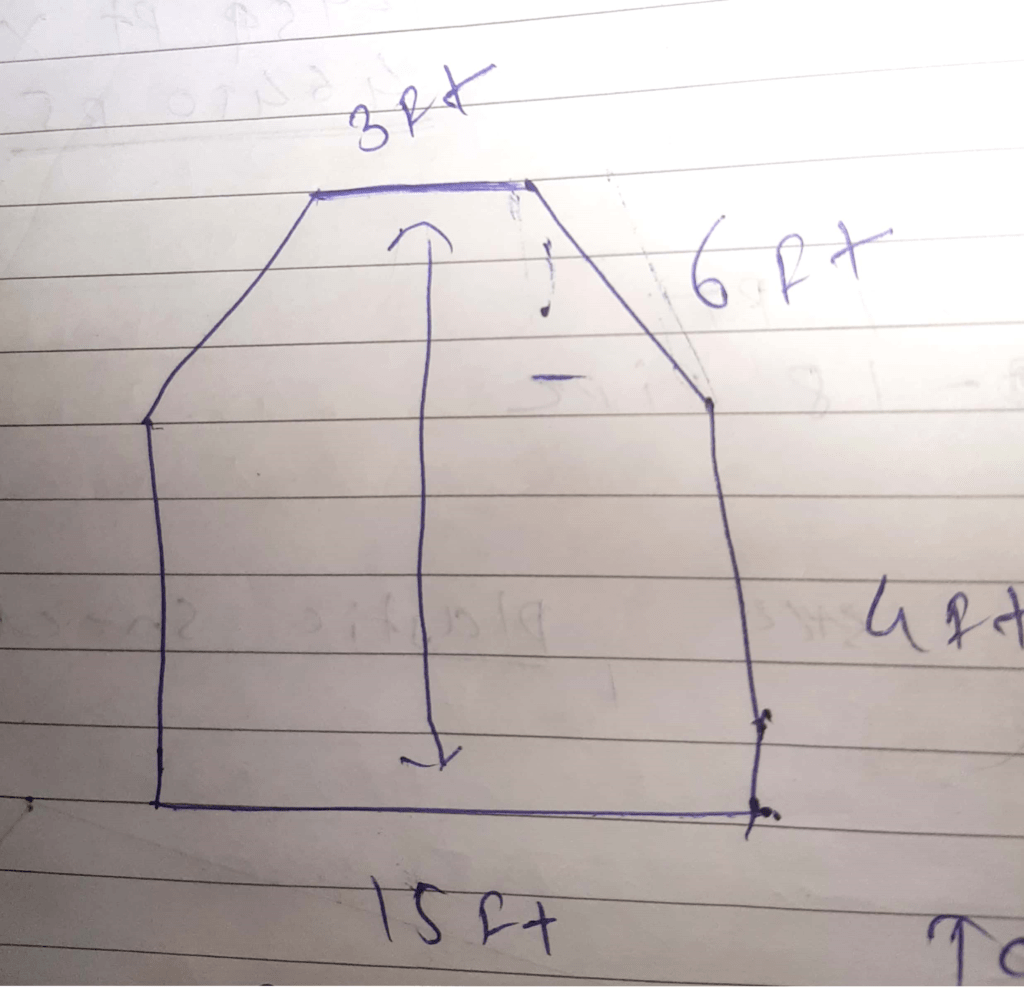

Pentagonal type tunnel dryer.

Pentagonal Tunnel dryer Specifications, Area & BOM

Size. Height 8 ft Width 15 ft & length 30 ft

bill of material 1>top sheet 762.7 square ft

2>front and back side …………..

3>structure

4>2-inch round pipe 64 ft =4 pipe

5> 1 inch pipe 222.8 ft= 12 pipe

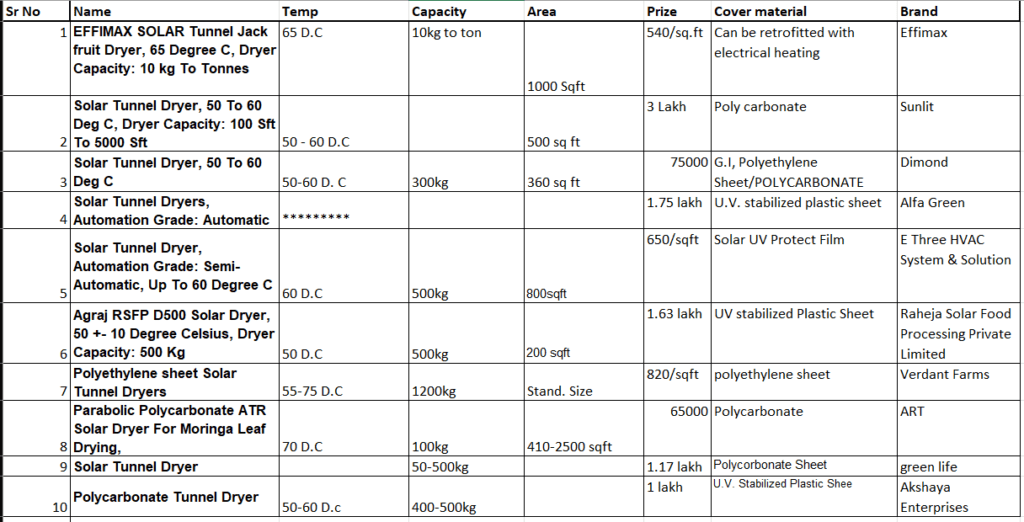

market survey

Pentagonal Tunnel Dryer.

TO finalize the pentagon Tunnel Dryer.

Pentagon Tunnel dryer Design finalize

Height 5.46 feet up to ground

Length 30 feet

width 15 feet

Angle each sheet 30 60 90 degree

BOM OF Tunnel Dryer ( GI Structure)

BOM Tunnel Dryer ( GI Structure)

Design of Tunnel Dryer