Introduction

Since I’m a fab lab intern, I’ve completed a variety of projects and activities there using fab lab tools like a laser cutter and 3D printer. For example, I’ve created a number of different types of mechanisms, including the Quick return mechanism, Single Slider Crank Mechanism, and Geneva Mechanism.

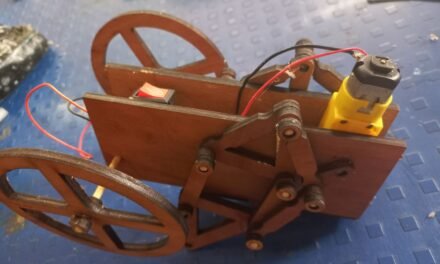

Firstly I designed a single slider crank mechanism in Solidworks first, and then I used a laser cutter to produce each component out of plywood one at a time. I then put all the pieces together to create the final mechanism.

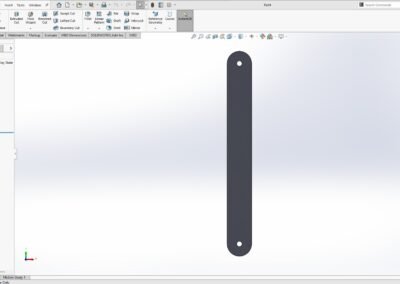

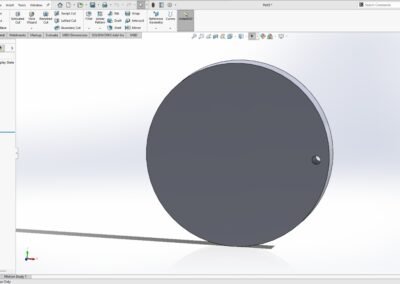

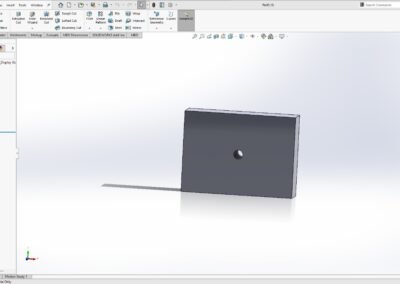

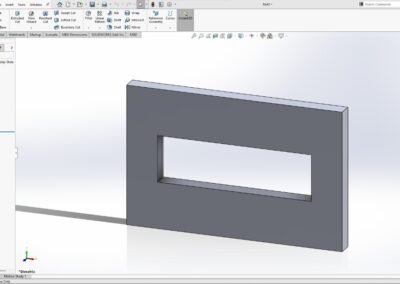

I created the cad models in this gallery.

I used a laser cutter to cut out each component of the mechanism shown in this photograph.

After using a laser cutter to cut each piece, I assembled the entire mechanism.

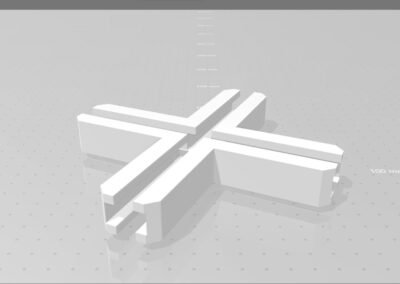

Later, I will develop and construct a Quick Return Mechanism. This mechanism was made using a 3D printer using the same procedure: first, I designed the mechanism in Solidworks; next, I created an STL file; next, I used a slicer to cut the file into separate components; and last, I assembled the printed parts.

I’ve included cad model stl files photos in this gallery.

Afterwards using a 3D printer to produce the parts.

I have gathered all the parts after 3D printing and put them together.

This mechanism is used in multiple locations, such as door lock systems and all security locks.

Thank You.