Problem Identification:

In market, there are many khowa making machine but all are working on external heating. Such as gas heating and motor for stirring the khowa is also operating on electricity, which is very costly. So the heating part is to be make on solar to reduce the cost of khowa.

Background:

Khowa is the premium byproduct of milk, used to make Gulabjamun, Different Mithai ( Sweets). During the making of khowa we need a continuous stirring the milk in container to avoid burning of milk. Different types of khowa making machines available in market but they are not economical. The heating operation requires maximum amount of energy, doing it on electricity and gas heating. Both the methods are very costly and makes pollution. So we decided to work on heating method of khowa making machine and decided the heat source as solar concentrator.

Types of user:

- Sweet marts

- Party caterers

- Backers

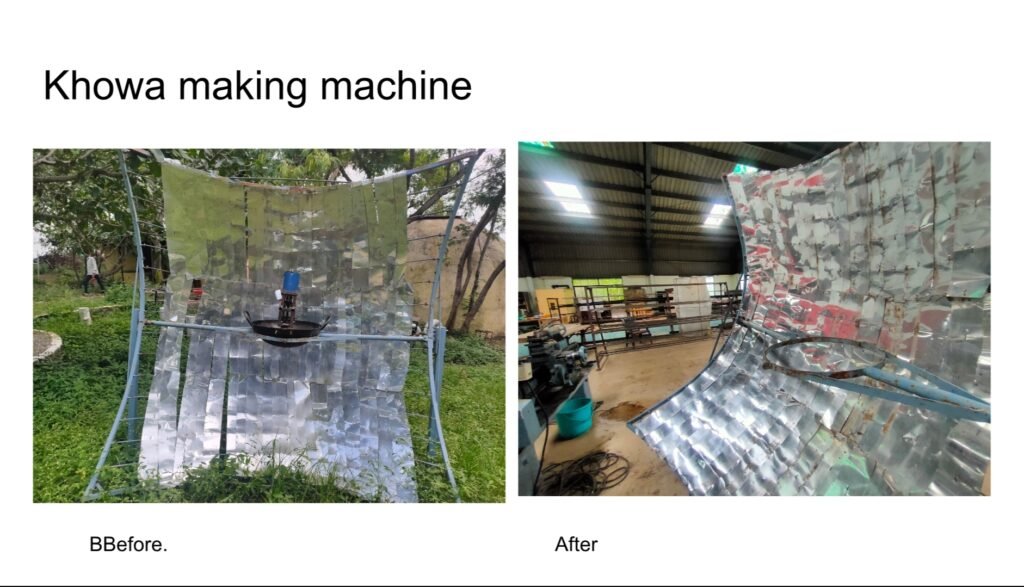

Design and development of Khowa making machine:

Earlier, this work done by Mr. Pratik Gajare, sharing the blog link of his work:

From above blog, the calculations for heat energy will require, stand and pan assembly, motor selection was done.

Now the task was to make the stirring blades mechanism to stir the milk in the pan, so started working on it accordingly.

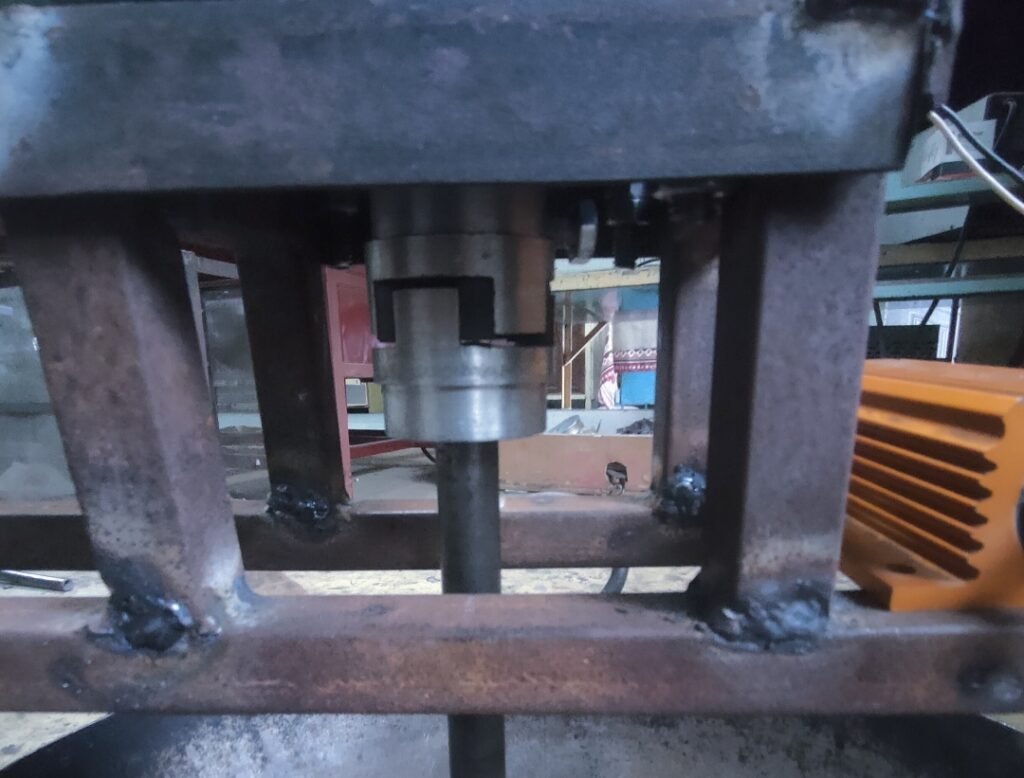

Selection of coupling for motor shaft and drive shaft for stirring:

For stirring operation in the pan, the coupling must be flexible so as to cover the most of the portion of pan. The love joy coupling has the same function, Flexible Jaw couplings are generally used to connect continuous-duty electric motors with driven machinery, pumps, and gearboxes. It allows the angular misalignment upto 1°.

after this coupling the driven shaft was being misaligned by 10° so, to bring it to 1° bearings mounted around the shaft to restrict the misalignment.

Now the shaft was rotating in alignment.

10 litres of water is now being covered with this blade, but need to increase the capacity for more output.

Further, trails taken on thick and densed floor batter, which was nearly same as of khowa.

The scrappers attached to the blade gave good results, all the matter from the bottom centre getting scraped well. So with this same design can go for actual trails on milk to make khowa.

Trail 1:

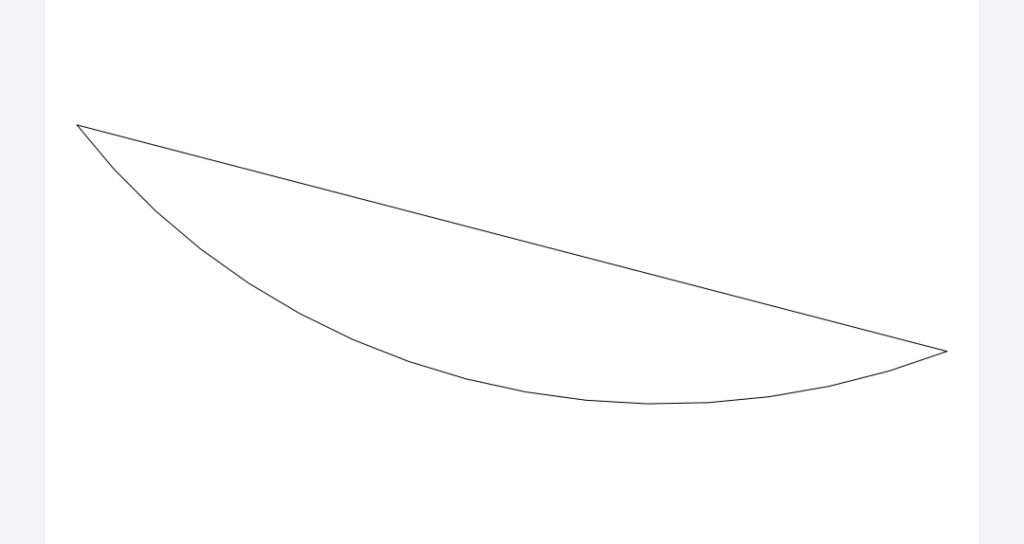

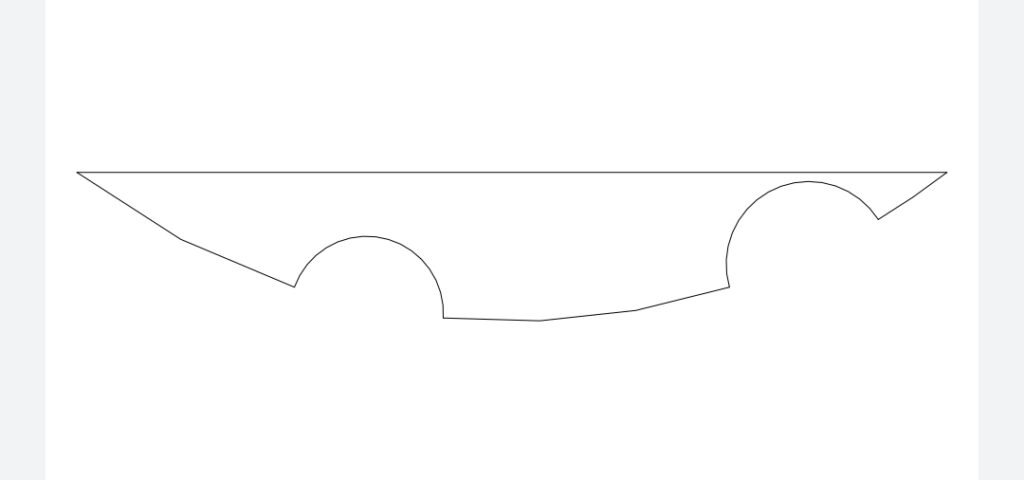

During this operation, one thing observed that, the upper side of the blade which is not in contact with the blade was remaining free after the evapration of milk. so we need to work on the design of blade again to keep all thre sides of blade should be in contact with the bottom of vessel to perform the operation in better way.

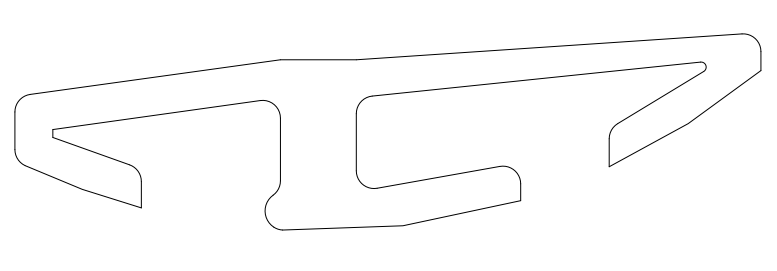

New Blade design:

The design consists of 3 scrapping arms and some gaps left between those arms to free flow of milk between them. 1st short arm will cover the gap between 2nd and 3rd arm, 2nd arm will all the centre portion of the vessel and 3rd arm will cover it’s space along with the gap between 1st and 2nd arm.

Likewise, all the arm are in operation and performing the movement of Khowa batter in vessel.

Trail 2:

During 2nd trials with new blade design optimization, the scrapping and mixing improved. During this trials, faced new challenge that need to overcome for the best performance of product.

The challenges was:

- The build quality of frame.

- Wiring, connection and control.

- Scrapper size.

- handling of Khowa making Machine

Now, to overcome these challanges, the Weldments should be as minimum as possible, the wiring should be neat and easy, the size of scrapper should be more than the gap between blade arm and vessel so as to perform the better scrapping and the last and important this is the machine should be easy to dismantle.

The design parameters need to be changed during 2nd iteration of this machine but the remaining part of wiring can be covered, so did some changes in wiring for connection of resistance and capacitor of motor.

After the successful 2nd trail now the main part of the project has take part of it. That is solar concentrator as heat source.

In trails taken on water, the highest temperature rise in 10 liter of water observed was 61°C. As the continuous stirring the temperature tend to decrease. In the prince 40 concentrator, the aluminium plates are very dusty and has scratches on it, so it’s reflectivity has dropped down. Therefore we couldn’t achieve the boiling point of water.

The results of 1st test taken are shown in document below:

https://docs.google.com/document/d/1vML4bdnY80DO3uKUph-8x9oqy9ModHexHD0EdAbIEFA/edit?usp=drivesdk

The concentrator has its foil overlapping on each other so the 4 meter square area is not covered by Al plates. Therefore the efficiency of that concentrator is low.

So the maintenance of concentrator was done.

in the maintenance, the arrangement of reflector Al plate made so as to cover all the surface area of concentrator to achieve its maximum performance.

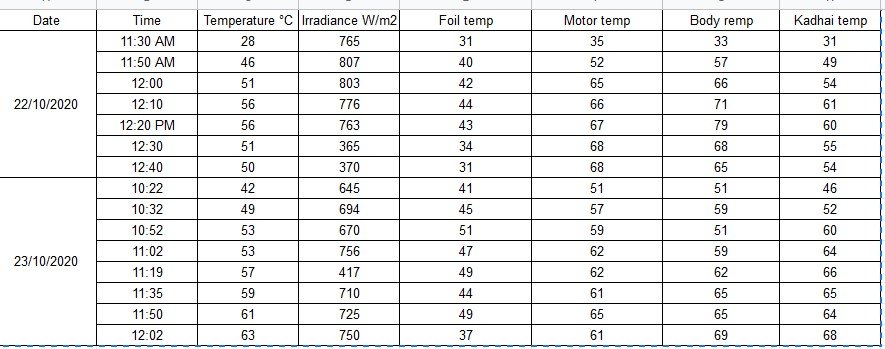

The performance results:

From the above data , the maximum temperature rise in water is 63 degree delicious. Due to variation in irradiance of sunlight the temperature of water varies. Another major observation is, the body temperature is higher than that of kadhai/ vessel temperature therefore it can be say that the concentrator can not concentrate the radiance on its focal point. If the concentrator concentrate the light accurately then we can achieve the highest temperature of water i.e. boiling point (100 degree delicious).

In the above trail, 2.7 liters of water got evaporated out of 5 liters in 4 hours, which are better results than the previous trails.

Energy calculation

Total energy consumed for 3 liter water evaporation from milk =

H1 – Energy required for heating milk

H2 – Energy required for evaporation of water from milk

H3 – Energy required for heating of kettle

H1= mass flow * specific heat capacity * temperature difference

H1= m * Cp * dT for milk

= 4*1.027 * 3.93 * (68-17)

= 823.36 KJ

H2 = m * dhvap at 68 degree celsius

= 3 * 2345

= 7035 KJ

H3 = m * Cp * dT for vessel

= 8.5 * 0.510*51

= 221.08

H1+H2+H3 = 823.36 + 7035 + 221.08

= 8079.44 KJ

Solar energy available = Time * Irradiance* area

= 4 * 3600 * 950 * 4

= 54720 KJ

Efficiency = (8079.44/ 54720)* 100

= 14.7% utilization

As our reflector is old and hence efficiency is 14. 7 % whereas the claimed efficiency is 45% i.e. 3.06 times higher.So, prince 40 can evaporate 3*3.06 = 9.18 liter of water every 4 hours from 11.00 Am to 3 PM.LPG required to evaporate 3.3 liter water is = 0.212 kg

Cost of LPG = Rs. 68/ kgTime: 2 HrsTherefore, to evaporate 3.3 kg water from milk to make khowa we spent 14.41 rupees of LPG.Wood required to evaporate same water from milk is = 2.12 kg

Cost of wood 8 rupees per kgTherefore 18.23 rupees of wood required to make 1 kg khowa

After using solar concentrator We will save heating cost thoroughly.

Suppose for 3 kg of khowa we will require 42 rupees of gas. This 1 batch of 3 kg khowa will require nealy 650 gram of gas.Therefore 42 rupees per day will become 8760 rupees per year.

Cost of our Solar concentrator based khoya making machine: 40000/-So the payback period : 40000/ 8760 = 4.5 years

| Parameters | Units | Wood | LPG | Concentrator | Remark Concentrator |

| Appearance | |||||

| Time required to evaporate 1 lt | hr/lt | 0.75 | 0.44 | 1.44 | Consumes more time compared to other technologies |

| Fuel Cost to evaporate | Rs/lt | 10.72 | 4.3 | 0 | Best |

| Electricity Cost | Rs/kg | 3.85 | 2.94 | 6.72 | It consumes more electricity because it take more time to evaporate the water out of milk, so the stirrng operation is continuous |

| Space required | Sq. mt | 2 | 1 | 4-6 | Comparatively more than other technologies |

| Set up cost | Rs/unit | 16200 | 17790 | 40000 | Comparatively cost is more than other technologies. |

| Khava production cost | Rs/kg | 14.57 | 7.24 | 6.72 | #VALUE! |

| Special operating conditions | Availability of firewood | Availability of LPG | Availability of sun irradiance | Very irregular or dependent | |

| Batch time | hr/batch | – | 1.75 | 4 | Consumes more time compared to other technologies |

| Advantages | 1.Easy availability of fuel 2.less space requirements, 3. | 1. No need to observe time to time, 2. Less space requirements, 3. no chance of dust contamination | 1. environment friendly, no CO2 emissions for heating source, 2. no costs for heating, 3. No hazards | ||

| Limitations | 1. chances of fire hazards, 2. adverse effects of smoke on human body, 3. high carbon emissions, pollution causing, 4. time to time observations required for wood consumption | 1. High amount CO2 emissions, no environment friendly, 2. Costly fuel, 3. limitations for vessel size | 1. time to time solar tracking required, 2.Dust Contamination 3. Space required 4. Heat irregularities based on weather conditions 5. Continuous requirement of operator to adjust the concentrator angle 6. Training required | ||

| Ease of use | 5 better to 1 worst | 2 | 4 | 3 | |

| Video links | https://photos.app.goo.gl/NYopCaXj9bmd3Ar9A | https://photos.app.goo.gl/2Pq4nF2LrViYNkmV8 | https://photos.app.goo.gl/8Lq8x8JhHCd72skQ8 |

From the above remarks, this project is not economical as the cost is very high and the labour cost is not getting minimised which is very important to think about. As we need the labour to track the sun rays in particular time interval, it is cost consuming thing.

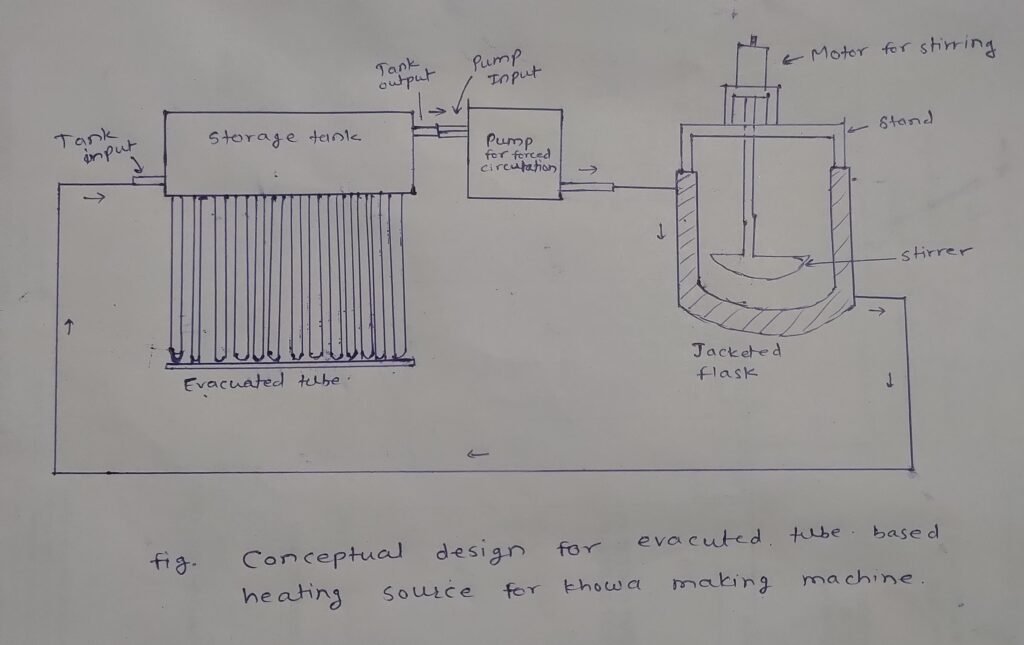

the alternative for the prince 40 concentrator is evaluated tubes based solar water heater, it has 3 times more efficiently, so it can be used as heating source.

Total energy consumed by solar water heater

Q = m * Cp * (T2-T1)

Q= energy absorbed by water to get heated

m= mass of water

Cp= Specific heat capacity

T= temperature

Q= 700* 4.18* (71-63) = 23408 KJ

By considering the 1 liter water evaporation Q will become around 26400 KJ.

Area covered by evacuated tubes= 5.72 m2

Area of empty space between those tubes = 2.47 m2

So the effective area of evacuated tubes = 5.72-2.47 = 3.25 m2

Therefore, in 3.25 m2 area total energy gain is 26400 KJ and that of the prince 40 concentrator was only 8079 KJ. which is more than 3 times.

Now, Solar energy available during the day= Time * Irradiance * Area

= 3600*6*822*3.25

= 57704.4 KJ

Therefore the efficiency will be = Output/Input =( 26400/57704)*100 =45.75%

Therefore the efficiency of evacuated tubes is 3 times greater than solar concentrator.

Document on Khowa making machine

https://docs.google.com/document/d/108Uyqanyop3zjpnpaAmQkPIrXnB2XdrlwSa6hddbArU/edit?usp=drivesdk