Water filter: Water purification, process by which undesired chemical compound, organic and inorganic materials, and biological contaminants are removed from water. One major purpose of water purification is to provide clean drinking water.The purification procedure reduces the concentration of contaminants such as suspended particles, parasites, bacteria etc. To avoid this contamination some people use RO filters, aqua-guards etc. to purify the water. RO filter remove most of the minerals from the water leaving it with an acidic pH. Also, during the purification process, up to 20 gal of water is flushed down the drain for every gallon of filtered water produced and requires electricity. TDS means total dissolved solids is the measure of dissolved minerals, salts, metals and impurities in water. As the TDS also includes the natural occurring minerals in the water like calcium, phosphorus, potassium. according to BIS (Bureau of Indian Standards) TDS under 500 is safe for human consumption. Since, RO reduces the hardness of water by 90% it will bring TDS down to non ideal state (Mineral water TDS range is in between 15-20). RO is phenomenal technology which was actually developed mainly for marines so that they can readily purify salt water and used for drinking purpose. So, we can said that, RO technology was developed for survival not for daily purpose. BARC ( Bhabha Atomic Research Center) filter is best option to remove bacterial contamination, turbidity and odour. This filter does not need electricity or addition of any chemical.

First check the TDS of the tap water in our house then decided which filter suitable for your house:

| TDS level | Type of water purifier |

| TDS < 300 | UF + UV |

| 900 > TDS >300 | NF + UV |

| TDS > 900 | RO |

Objective:

- To design cartridge to remove insoluble impurities

- To make affordable and replicable water filter system to get drinkable water. It will work on solar power if any electric power is required.

- To get drinkable water

- To remove bacterial contaminant from water

Project Description:

Today, 90% of villages in India depend on groundwater for drinking water. Clean water is essential for every human being, for drinking, cooking and other daily uses. As per the research contaminated water lead the diseases like- diarrhea, cholera, dysentery, typhoid and is estimated to cause 502000 diarrhea deaths each year.The regular tap water being supplied in your home might seem clear but possess various sorts of health-affecting bacteria and viruses such as fluorine compounds, chlorine, lead, pesticides and other types of waste particles. Clean and safe water is a fundamental human need. BARC filter is best option to purify water. This filter based on ultra filtration membrane can physically remove bacteria, suspended solids and high molecular weight organics without the use of electricity, at tap water pressure, mainly by size-exclusion mechanism.

Required material and specification:

i) Pre-filter

| Sr. No. | Material | Specification | Quantity |

| 1 | DC pump | Diaphragm pump B.N.Q.S. ( DP -125 -300 -1W) Volt: 24 VDC Amp: 2.5 A Open flow: 5 Lpm Throttle: 1900 cc Suction Height: 2 m Inlet pressure: 15 ~ 90 psi Working pressure: 82 ± 8 PSI Pressure setting: Bypass: 125 PSI | 1 |

| 2 | AC-DC Adapter | Model: 105 A Input: 110-300 V AC Output: 24 V DC – 2.5 A (Max.) | 1 |

| 3 | Solenoid valve | 3/4 inch AC 220 V, 50 Hz Solenoid Valve Electric Water Valve N/C Control Equipment | 1 |

| 4 | Pipe | 4 mm, 6 mm inner diameter, 1/4 Pipe Food Grade Material | 2 m each |

| 5 | L and T | 1/4″ & 3/4″ optional elbow, 1/4 thread connectors, double push connectors, membrane housing connectors, pump connectors, t-connectors | 6 piece each |

| 6 | Teflon Tape | Water seal, PTFE thread seal tape 12mm × 0.1mm × 10M | 10 |

| 7 | Frame with pre-filter’s candle | Dimensions: | 1 |

| 8 | Polypropylene filter (PS- 05) | 5 micron Sediment, dirt and rust removal | 2 |

| 9 | Sedimentation filter | 1 | |

| 10 | Carbon Filter Cartridge | Maximum flow- 120 LPM, Maximum pressure – 9 Bar Maximum temperature- 45°C Service life: 7500 liter | 1 |

| 12 | Connecting Wires | Polycab cables & wires, Type/code: single core- unsheathed/Y Grade: 1100 V, Size: 1 sq. mm | 3 m |

| 13 | Plug | 2 pin, 10 A, 220-240 V, socket compatible with plug type C | 2 |

| 14 | BARC filter | 2 | |

| 15 | UF membrane | pore sizes in the range of 0.1 to 0.001 micron Burton UF membrane is made of PAN alloy. | 2 |

| 16 | UV tubes | 11 W, 34 V, 4 pin single ended, 9.8 inches | 2 |

| 17 | Chokes | UV choke AC 220 V, Suitable for 11 W UV tube, 1/4 2 Connectors | 2 |

| 18 | UV chamber | UV Chamber Barrel for 9.8 inches UV tube | 2 |

| 19 | Flow valve | Inlet Valve Set 1/4″ Size, Made up of Brass Material | 2 |

| 20 | H2S bottle | H2S strip Bacteriological field test kit for drinking water | 10 |

| 21 | Storage tank | capacity 200 Liter | 1 |

| 22 | Frame for BARC filter | Length: 35 cm, Breadth: 1 cm Inner diameter: 9 cm, Outer diameter: 10cm | 1 |

Other material: multimeter, soldering gun, insulating tape, pipe and wire cutter, etc.

Assembly of filter:

Steps: a) To measure discharge rate in dream house filter:- Discharge rate: 42 min / lit to measure discharge rate in kitchen’s filter:- Discharge rate: 12 min / lit

b) Then check output of the previous filter in dream house and kitchen Result: i) Dream House: H2S test: Positive (black colour) ii) Kitchen: H2S test: Negative (Yellow colour)

c) The tank of the dream house does not have enough head so we need a pump. So measure the discharge of the BARC filter with pump (Standards: BARC filter requires: 30 PSI pressure, Discharge rate: 10 min / lit ). Specification of pump: Submersible pump Model THS 3000 Volt: 240-50 Hz Power: 35 watt max, Head: 3 Discharge: 1200 LPH max

| Sr. No. | Discharge rate (min) | Quantity of water |

| 1 | 12 | 1 lit |

| 2 | 14 | 1 lit |

| 3 | 10 | 1 lit |

| 4 | 12 | 1 lit |

| 5 | 10 | 1 lit |

| 6 | 16 | 1 lit |

- When two BARC connect in series:- discharge rate: 16 min / lit

- When two BARC connect in parallel:- discharge rate: 7 min / lit

d) Then the pump connected to the input of the BARC filter but the water was not drawn through that pump. So decided to use another 300 watt pump. Bypassed the output of the pump as the pressure of this pump was high.

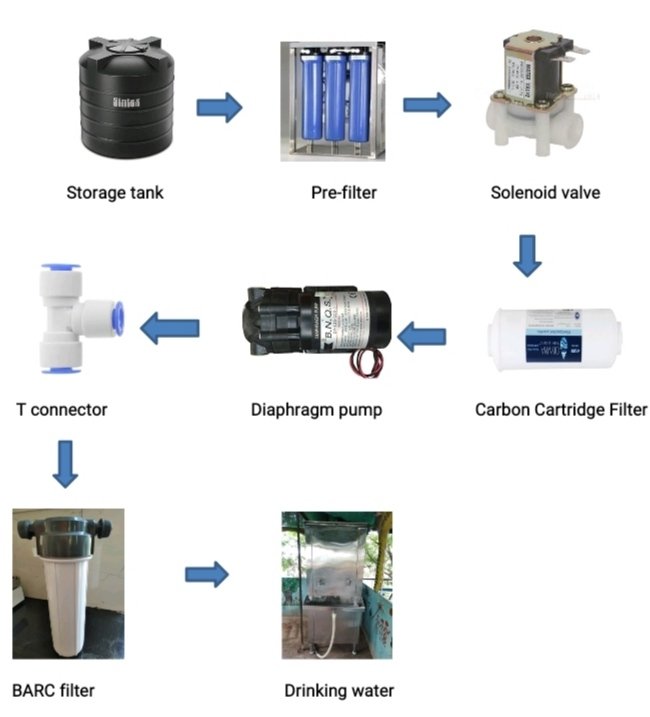

- Assemble the pre-filter 1. Open the pre-filter caps and insert the provided pre-filter candles like polypropylene, sedimentation and again with polypropylene. Firmly close the filter cap. Preferably use Teflon tape to achieve a complete seal. Now attach the elbow connectors on both sides of each filter. 2. After this assembly, connect output of pre filter connect to input of the solenoid valve.

- Assemble the BARC filter 1. Open the BARC-filter caps and insert the provided UF membrane candles. First wrap properly teflon tape to the thread of elbow connectors then attach this connector to the filter. 2. Connect two BARC filters in series. Take output from the second BARC filter. 3. Outlet of the second BARC filter is given to the UV tube.

- Bypass assembly of the motor 1. Take the motor (Volt: 24 VDC Amp: 2.5 A Working pressure: 82 ± 8 PSI) and input connected to the outlet of the output of the carbon cartridge filter with the help of a pipe(6 mm) which is attached to the outlet of the solenoid valve. 2. Take output from the pump and connect with the T connector (Bypassed the output of the pump as the pressure of this pump was high.). 3. The Adapter terminals connect to the motor terminals as per polarity.

Connection

- First connect the flow valve to the outlet of the tank. Take input from the flow valve to the pre filter assembly.

- Inlet of solenoid valve connected to the pre filter output.

- The output of solenoid valve connect inlet of carbon cartridge filter and output of this is connected to the pump.

- Take one output of the pump to the BARC filter assembly and another to the water tank.

- Install the whole assembly and then take output from UV tubes and give to the storage tank.

- Take an H2S test of the output of the filter. If it is negative then it is drinkable.

d) Connect pre-filter before BARC filter and then check the output of filter

i) pre filter :- Discharge rate: 17 sec / lit H2S test:- Positive (black colour)

ii) BARC filter (6) :- Discharge rate: 5 min / lit H2S test:- Positive (black colour)

iii) BARC filter (3) :- Discharge rate: 2 min / lit H2S test:- Positive (black colour)

iv) BARC filter (0) :- Discharge rate : 10 min / lit H2S test :- Positive (black colour)

e) from the above result, decided to install UV tubes after BARC filter and then check the output of filter. Discharge rate from pre-filter: 28 sec / lit i) BARC filter :- Discharge rate : 12 min / lit H2S test :- Positive (black colour) ii) UV filter :- Discharge rate : 9 min / lit H2S test :- Positive (black colour)

f) But the H2S test result of the dream house filter is positive. So take the H2S test without a motor and with a motor. a) without motor :- Discharge rate : 1 hour / lit H2S test :- Negative (Yellow colour) b) with motor :- Discharge rate : 12 min / lit H2S test :- positive (Black colour)

g) Change the UF membrane inside the BARC filter. Then check the output of filter. i) Discharge rate from BARC filter: 15 min / lit H2S test :- Negative (yellow colour) ii) Discharge rate from UV: 15 min / lit H2S test :- Negative (yellow colour)

h) Installed storage tank in Dream house.

Kitchen filter a) As the flow of the filter in the kitchen was very slow, so checked the filter and then take test but result of H2S test is positive.

b) Then check all parts of the filter and change some parts of it. and then check the output of filter. a) When flow valve is half open. Discharge rate : 6 min / lit H2S test :- Negative (Yellow colour) b) When flow valve is fully open Discharge rate : 3 min / lit H2S test :- positive (Black colour)

In BARC system, when candle changes pressure and flow rate of water also change. so now in our filter BARC candles are not used.

Now I design sand filter cartridge to remove insoluble impurities from water before the filter. In this filter, we used fine sand, gravels, charcoal and sandstones.

Sand Filter: Sand filters are used as a step in the water treatment process of water purification. There are three main types; rapid(gravity) sand filter, upward flow sand filters and slow sand filter. All three methods are used extensively in the water industry throughout the world. The first two require the use of flocculant chemical to work effectively while slow sand filters can produce very high quality water with pathogen removal from 90% to >99% (depending on the strains), taste and odour without the need for chemical aids. Sand filters can, apart from being used in water treatment plants, be used for water purification in singular households as they use materials which are available for most people.

Sand filtration is used for the removal of suspended matter, as well as floating and sinkable particles. The wastewater flows vertically through a fine bed of sand and/or gravel. Particles are removed by way of absorption or physical encapsulation. Sand filters remove particulate matter, impurities that are not dissolved. When gravel, pebbles and different types of sand are mixed together vigorously in water they settle to the bottom of a tank by specific gravity, most dense first; rocks, gravel, pebbles, coarse sand and finally, fine sand on top. fine sand: The fine sand purifies the water of small insoluble particles. charcoal: Adsorption binds impurities chemically on the surface of the charcoal filter rather than physically absorbing them. Activated charcoal is the ideal water filter because it removes toxins from the water without stripping the water of salts and important minerals. Gravels: Layers of sand and gravel, arranged according to density and sand particle size, trap and strain particles in the water Drawback of sand filter: it does not purify the water from bacteria and heavy metals. So after filtration the water should be UV treatment to kill bacterial.

Required material for the sand filter

| Sr. No. | Material | Quantity |

| 1 | 90mm PVC pipe (1foot) | 1 |

| 2 | End cap (90mm PVC pipe) | 2 |

| 3 | ½” FTA | 4 |

| 4 | ½” Tank nipple | 2 |

| 5 | Union | 2 |

| 6 | Hose clip | 2 |

| 7 | End plug | 2 |

| 8 | Elbow | 1 |

| 9 | Teflon | 1 |

| 10 | PVC solution | 1 |

| 11 | ½” UPVC pipe(1 foot) | 1 |

| 12 | Flexible pipe (PVC suction pipe) | 1 |

| 13 | Fine sand | 200 gm |

| 14 | Gravels | 150gm |

| 15 | Bigger size sand | 150 |

| 16 | Charcoal | 250g |

Assembly of the sand filter cartridge 1. 1. Take a 90mm end cap and Make a hole diameter of 2 cm on the top of it with the help of a hand drill machine and connect the union both end caps.

2. Then take 1 ft 90mm PVC pipe and apply PVC solution to the middle of the end cap and fix one end of PVC pipe in it.

3. Put net inside the pipe and make layers of stones(150gm), charcoal(200gm), gravels(200gm) and fine sand(250gm) respectively. Put mesh between two layers.

4. Close the PVC pipe by end cap.

5. Then connect FTA and union to the both sides. Connect (Length 40mm) ½” upvc pipe in between union and FTA connection.

6. Lower part of the sand filter connects one FTA to the union using ½” upvc pipe. Then connect nipple.

7. Upper part of the sand filter connects the elbow to the union by using ½” upvc pipe.

8. Join the nipple to the flexible pipe and connect to the water tank.

Assemble of the prefilter

Step 1: First take teflon tape and roll around the cap of filter and L shaped connectors.

Step 2: Preferably use Teflon tape to achieve a complete seal. Now attach the elbow connectors on both sides of each filter.

Step 3: Attached cap to the frame with the help of screws.

Step 4: Open the pre-filter caps and insert the provided pre-filter candles like polypropylene, sedimentation and again with polypropylene. There are three candles connecting one sedimentation filter in between two polypropylene filters. All candles connect to the cap of candles.

Step 5: Then connect the pipe in between the outlet of the first candle and inlet of the second candle. Then connect the pipe to the outlet of the second candle to the inlet of the third candle.

Step 6: Then take a carbon cartridge and connect L connectors to both sides. Fit C shapes stand on the top of the frame by using screws. Connect outlet of the third candle of pre-filter to the inlet of carbon cartridge.

Step 6: Take the UV chamber and fit the UV tube inside to it. Connect L collectors to the UV chambers.

Step 7: Then fix C shape to stand for the UV chamber on top of the frame. Fit the UV chambers inside the C shape stand. Then connect the adapter to the UV tubes.

Step 7: Then connect the pipe from the outlet of the carbon cartridge to the inlet of the UV chamber.and Outlet of one UV chamber is inlet of second UV chamber.

Take an outlet from the second UV chamber.

Step 8: Connect output of the pump to the input of the prefilter.

Assemble of the pre filter

Step 1: Outlet of pump gives to the inlet of first candle of pre filter. There are three candles connecting one sedimentation filter in between two polypropylene filters.

Step 2: Open the pre-filter caps and insert the provided pre-filter candles like polypropylene, sedimentation and again with polypropylene. Firmly close the filter cap. Preferably use Teflon tape to achieve a complete seal. Now attach the elbow connectors on both sides of each filter.

Step 3: After this assembly, connect the output of the first candle to the input of the second candle (Carbon candle), similarly to the output of the second candle to the input of the third candle.

Step 4: Connect output of the pump to the input of the prefilter.

Connections of the filter:

- First connect the sand filter before the UV filter to the output of the tank.

- Then connect the flow valve to the outlet of the tank. Take input to the pump and then connect output of pump to the pre filter assembly.

- The output of the pre filter connects to the inlet of carbon cartridge filter and output of this is connected to the UV chamber.

- Install the whole assembly and then take output from UV tubes and give to the storage tank.

- Take an H2S test of the output of the filter. If it is negative then it is drinkable.

Specification of filter:

| Sr. No. | Features | With pump | Without pump |

| 1 | Color | Blue | Blue |

| 2 | Capacity | 21L/hr | 21L/hr |

| Stage of purification process | 6 stages | 6 stages | |

| 3 | Power consumption | 60 W | 30 W |

| 4 | Operating input voltage | 230V AC, 50Hz | 230V AC, 50Hz |

| 5 | Product dimensions | 45 cm X W 26 cm X H 66cm | L 45 cm X W 26 cm X H 66cm |

| 6 | Cost without solar | 12433.5 | 9733.5 |

| 7 | Cost with solar | 34433.5 | 28,781.5 |

Solar Design: i) Total wattage: 60.8 W Total watt-hours: 364.8W-hr Solar system designing for water filter with pump

| Sr. No. | Part of solar system | Quantity | Sizing/ capacity | Cost |

| 1 | Inverter | 1 | 150W | 5310 |

| 2 | Panel | 2 | 80W | 5019 |

| 3 | Battery | 2 | 12V,150Ah | 11,000 |

| Total cost of system | 21,329 |

ii) Total wattage: 60.8 W Total watt-hours: 364.8W-hr

| Sr. No. | Part of solar system | Quantity | Sizing/ capacity | Cost |

| 1 | Inverter | 1 | 100W | 4900 |

| 2 | Panel | 1 | 80W | 2509 |

| 3 | Battery | 1 | 12V,60Ah | 5500 |

| Total cost of system | 12909 |

Market research

| Sr. No. | Name of filter | Filtration Capacity | Cost |

| 1 | Kent Grand UV Water Purifier | 60 L/hr | 15,000 |

| 2 | Eureka Forbes Aquasure Aquaguard Splash RO UV MTDS Water Purifier | 6 L | 17,999 |

| 3 | NBIRT solar water purifier | 50 L/ hr | 1,10,000 |

| 5 | Blue star (RO+UV) | 8.2L/hr | 31,900 |

Poster of the water filter:

This water filter replicate in Gurukul School (Ashram Shala)