Objective:

To design the 'Evaporative cooling system' for preserving agricultural produce for Pabal region farmers.

Deliverables:To fabricate the prototype of Evaporative cooling unit.

Need of project:

# Generally,the Pabal is as rural agricultural region in pune. where the farmers grow the good quality agricultural produce.

# The Pabal region farmers doesn't have any option to store agricultural produce in summer season and because of this reason most of the agricultural produce get waste.

# Considering the agricultural produce storing problem of farmers in Pabal region we decided to design a cooling system based on natural evaporation cooling principle without consuming electricity.

What is Evaporation ?

In evaporative cooling system, vaporization process takes place. Temperature of dry air decreased through vaporization, which can cool air. It required less energy than refrigeration. The evaporative factor depends upon flow of air, temperature and humidity. It requires higher flow of air and temperature but lower humidity.

Data collection of Pabal region:

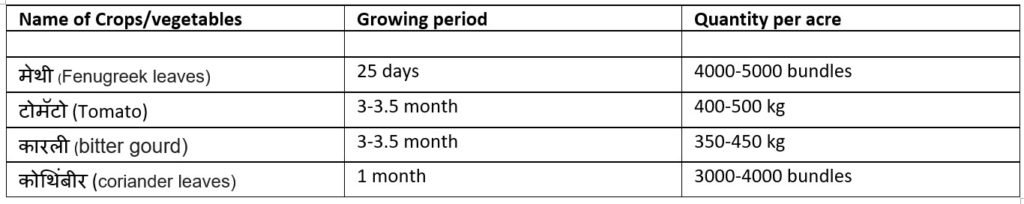

Agricultural produce data of Pabal in summer season:

Generally,the major crops grow in pabal farms during summer season (March - June) are as shown in below table;

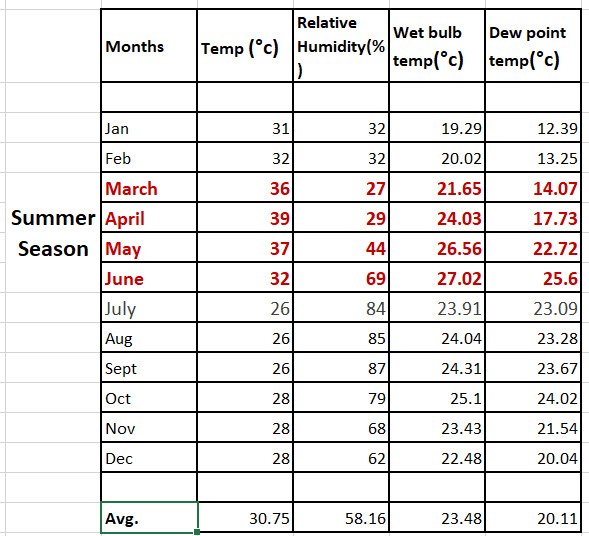

Weather data of Pabal for 2019 year:

The below table shows the 2019 year temperature data of Pabal

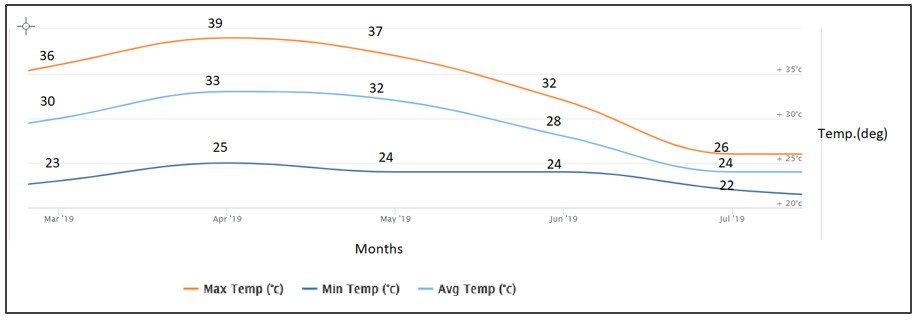

Graphical representation of temperature of pabal during summer season 2019:

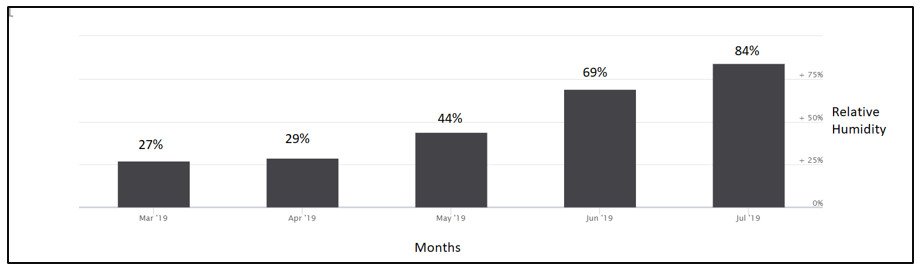

Graphical representation of relative humidity of pabal during summer season 2019:

Previous work did on Evaporative cooling system:

In 2017-18 the DIC fellow in Vigyan Ashram "Komal Raut" did some work on Evaporative cooling system as mention in below link:http://vadic.vigyanashram.blog/author/komalraut/

Problems created in previous Evaporative cooling system:

- The inside temperature of cooling system was not going below the wet bulb temperature.

- The inside relative humidity of cooling system is high compare to outside,because of the high humidity the microbes grow rapidly on vegetables inside chamber.and due to the microbial growth the perishable vegetables & fruits get spoiled.

Parameters needs to work on:

- Technically,the inside temperature of cooling chamber not going below wet bulb temperature so we try to work on sub wet bulb temperature.

- Due to high relative humidity the microbes grow on vegetables which are stored inside the cooling chamber .so we try to work on drop the Relative humidity of cooling chamber.

- Try to work on cooling materials.

- Pad thickness

- Pad orientation

- Pad density

- Pad face velocity

- Pad volume

- Water flow rate

- Air flow rate

- Channelisation of water and air

Possible ways to decrease the Relative humidity inside the cooling chamber:

1) Using following dehumidifying desiccants:

Calcium chloride,Calcium sulfate,Activated carbon,Zeolite,Silica gel,Rock salt,Damprid,Dri-Z-air,Baking soda

2) Using moisture absorbing plants:

Platicerium bifercatum (staghorn fern), Asplenium nidus (birds nest) , Aloe vera, Sansevieria trifasciata (snake plant)

Possible cooling materials which can be used for Evaporative cooling system:

Coconut coir pads,Jute fiber pads,Sackcloth pads,Rockwool,Clay,Brick bats,Date palm fibers and leaves,Wood shaving,Saw dust,Wheat straw,PVC sponge,Morum,Pumice stone,Rice husk,Charcoal,Cotton fabric,Green house shedding net etc...

First proposed design

Concept 1.

Windchill cooling unit( Cooling system without using water )

How the system works:

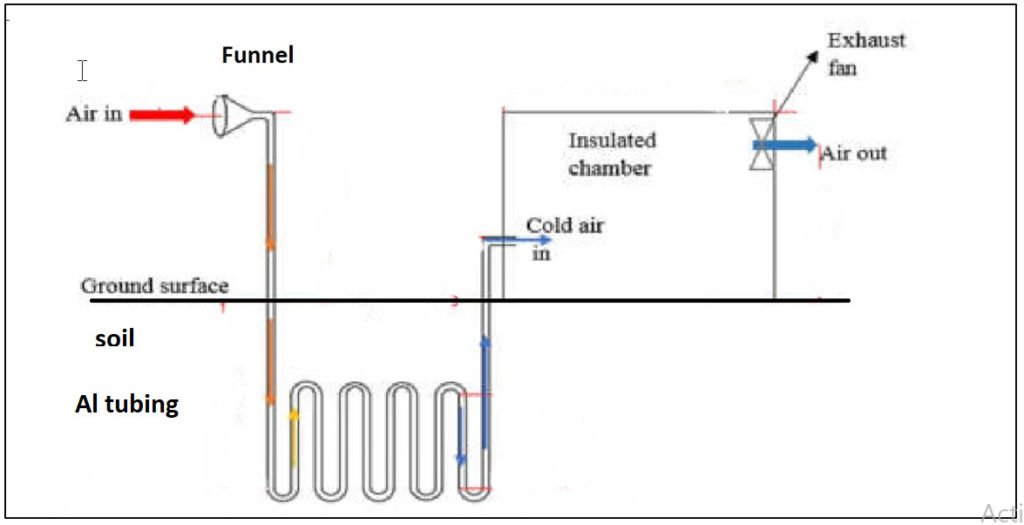

Above image shows the cooling system without using water,this system working on outside air.

This system is divided into two parts:

1) Aluminium tubing

2) Insulated storage chamber

The outside warm air enter through funnel by exhaust fan which is fitted at the end of insulated chamber.This warm air is passing through aluminium tubing which is connected to funnel.Some of the tubing portion is place below the ground level for heat exchange purpose between cold soil and warm air.

then cool air is supplied to insulated chamber through aluminium tubing.then the stored vegetables get preserved.

Design parameters of cooling system:

1) Capacity of cooling system:

# Generally,we design the cooling system for summer season

# In summer season the tomato production is near about 400-500 kg and bitter gourd is about 350-450 kg per acre

# Considering net production quantity of agricultural produce per acre in summer season,we decided to design a cooling system of capacity 680 litre

# If the production is more than the 680 liter capacity,then we suggest to install two or more systems instead of single one.

2) Dimensions of storage insulated chamber:

# L X W X D = 4 X 3 X 2 (in foot)

# capacity /volume of chamber= L X W X D

= 4 X 3 X 2

= 680 liter.

3) Material :

# Aluminium tubing for cooling outside warm air .

# Thermal properties of aluminium : Density=2.7 gm/cc

Thermal conductivity=205 W/(mk) Specific heat capacity=0.9 KJ/(kg.k)

# Food storage insulated chamber is made up of polystyrene sheet of 1 inch thickness

# Thermal properties of polystyrene: Density=0.96 gm/cc

Thermal conductivity=0.033 W/(mk)

Specific heat capacity= 1.3 KJ/(kg.k)

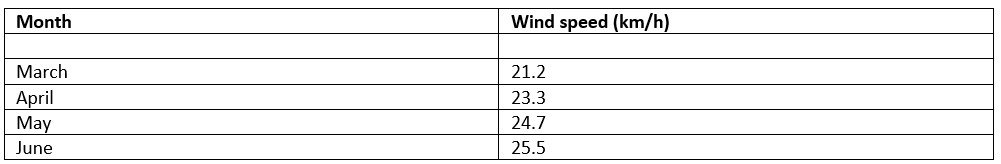

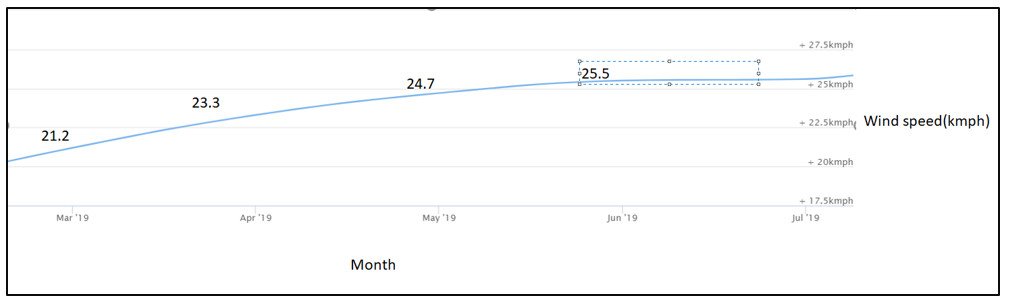

Wind speed data of pabal in summer 2019: (March-June):

Graphical representation of wind speed data of pabal in summer season 2019

Thermal properties of soil:

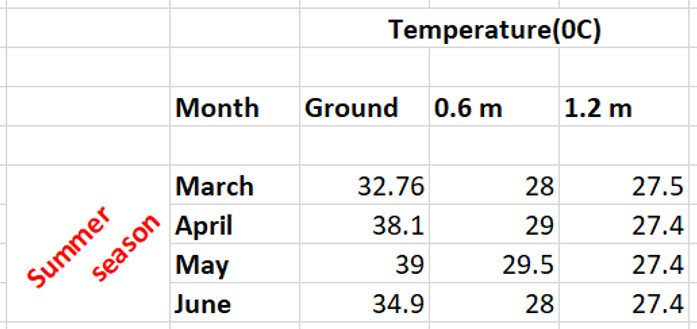

1) Temperature of soil:

Below image shows the temperature of soil at ground level and

2) Specific heat:

Definition: heat required to raise the temperature of a unit mass of a substance by 1 degree Celsius.

unit: KJ/Kg K

Specific heat of dry soil is 0.2 Cal/gm0C and water’s specific heat is 5 times higher than that, i.e. 1Cal/gm0C. Moist soils are generally cooler because the heat energy gets spent in evaporation of soil moisture

Calculations of soil:

L X W X D = 3 X 1.5 X 3 (ft)

Volume of pit = 13.5 ft3 = 382277.4 cc

Density of soil=2.65 gm/cc

Mass of soil= density X volume

=1013.04 kg

Consider, Pabal region soil contain 6% moisture per 100 gm soil

Sp. Heat of water= 1 Cal/gm0C &

Sp. heat of dry soil=0.2 Cal/gm0C

Total mass of soil is 1013 kg

Since soil moisture is expressed as gm of water per 100 gm of dry soil, there are in this case 60,780 gm of water with each 952,220 gm of soil.

The number of calories required to raise the temperature of 60,780 gm of water by 1°C is,

60,780 gm X 1 Cal/gm0C = 60,780 Cal/0C

Again, the number of calories required to raise the temperature of 1013000 gm of dry soil by 1°C is,

952,220 gm X 0.2 Cal/gm0C =190,444Cal/0C

So, total of (60,780 + 190,444) = 251,224 Cal/0C is required to raise the temperature of 1013000 gm of the moist soil by 1°C Specific heat of the soil = 251,224/1013000 = 0.248cal/gm 0C

Therefore,

Specific heat of Pabal soil =0.248cal/gm0C

Total heat capacity of Pabal soil= 251,224 Cal/0C

Volumetric Heat capacity (cal/cm3.0C): Cv= ρ c = 2.65 X 0.248= 0.6572 cal/cc.0c

Calculation of air:

Volume of pipe= ( pi X r2 X l )

=(3.14 X 0.1 X 24)

= 7.54 cube feet

= 214 liter

Volume of pipe is 214 liter

mass of air= density of air X volume of pipe

=0.0013(gm/cc) X 213509

=278 gm

so, 278 gm air passing through aluminum tube

Heat capacity of outside warm air at 39 °C = m X cp X dt

=278 X 1 x 312.15

= 86.8 KJ

so, the heat capacity of outside warm air at 39°C = 86.8 KJ

Heat capacity of air after getting temperature drop by 12°C

=m X Cp X dt

= 278 X 1 X 285.15

= 79.3 KJ

Heat capacity of air after getting temperature drop by 12°C =79.3 KJ

Amount of heat transfer by air to soil= 86.8 (KJ)-79.3 (KJ)

=7.5 KJ

Total 7.5 KJ amount of heat transfer by air to soil .

By using the Fourier law, calculate thickness of heat transfer

Q=K X A X dt/dx

7.5=0.5 X 0.42 X 285.15/dx

dx = 0.007 m

dx =7 mm

7.5 KJ amount of heat is transfer upto the next 7 mm soil thickness with surface area 0.42 m2

Problems created in Windchill cooling system:

1) The system not working on Evaporative cooling principle.

2) The outside air temperature not reach upto wet bulb temperature.

3)

Second proposed design

concept 2:

Evaporative cooling system based on radiator

How the system works:

The image shows the Evaporative cooling system base on radiator .In that we used the 20 liter capacity bucket containing water placed at some height & the heat exchanger radiator is placed on ground.for equal water distribution we used drip irrigation system on radiator.

we blow the ambient warm air by blower through radiator Copper tubes and due to evaporation phenomenon the warm air get cool at certain temperature drop & that cool air get supply to insulating storage chamber preserving agricultural produce.

Physical setup of Evaporative cooling system using heat exchanger/radiator:

fig 1.

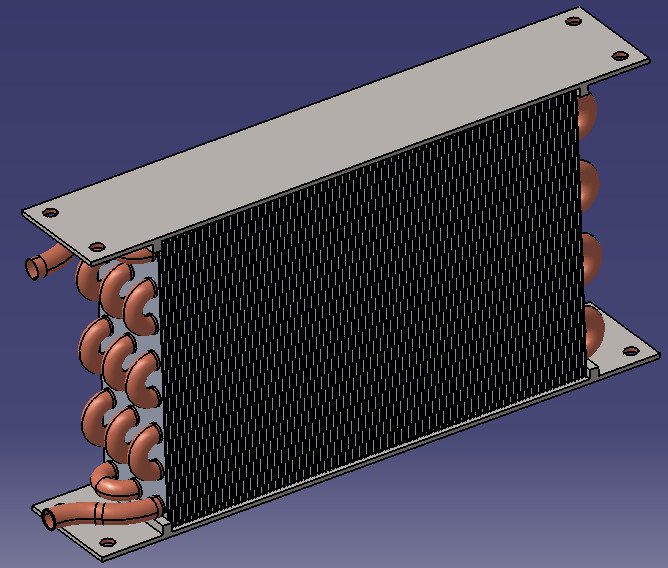

2D sketch of radiator

3D CAD model of Radiator:

Design parameters of the system:

Dimensions of radiator:

Length=66 cm, width = 48 cm, thickness= 9.5 cm

Cu tube diameter =1 cm

No of U-shape coils=32

Total length of Cu tube=140 ft

Area of Cu tube= Pi X L X D=3.14 X 4267.2 X 1

=13,399.008 cm2

Area of Cu tube =14.4 sq.ft

Volume of CU tube=pi X r2X L

=3.14 X 0.52 X 4267.2

= 3,349.752 cm3

=0.11 ft3

= 3.35 liter

So, total volume capacity of Cu tube is 3.35-liter

Mass of air flowing through Cu tube= density of air X volume of tube

= 0.0013(gm/cc) X 3,349.752 cm3

So,total 4.35 gm mass of air passing through copper coil

Blower specifications:

Voltage=230 V

Frequency=50 Hz

Current=1.5 A

Power consumption=335 Watt

RPM=13000 rpm

Discharge/flow rate =2.3 m3/min= 2.3 X 35.31=81.2 CFM=2300 lit/min

Trial experiment:

The physical setup of experiment is shown in fig (1)

Surrounding temperature=310C

Relative humidity=61%

Wet bulb temperature =25.060C

Blower air temperature=35 0C

Cold air temperature= 260C

Bucket features: capacity=20 liter

water Flow rate through bucket=0.125 lps

Dripper features: water flow rate through single dripper =0.025 lpm

Total drippers used =8

So, total flow rate of all 8 drippers = 0.2 lpm

Heat transfer calculations:

Heat carrying capacity of ambient air=m cp dt ………………….(at temp 31 0c)

=4.35 X 1 X 304.15

=1323.05 Joule

Heat carrying capacity of blower air=m cp dt …………………..(at temp 35 0c)

=4.35 X 1 X 308.15

=1340.5 Joule

Heat carrying capacity of cold air=m cp dt ……………………..(at temp 26 0c)

= 4.35 X 1 X 299.15

= 1301.3 Joule

Heat transferred by hot blower air=1340.5-1301.3 =39.2 Joule

Heat transferred by hot blower air=39.2 Joule (9.4 calories)

conclusion of experiment:

when the surrounding atmospheric temperature is 31 0C & relative humidity is 61% then wet bulb temperature would be 25.06 0C.

when the warm blower air of temperature 35 0C is passing through inlet of radiator then we get the cold air of temperature 26 0C through outlet of radiator & during the process the air transfer 39.2 joule heat

Third proposed design

Concept 3:

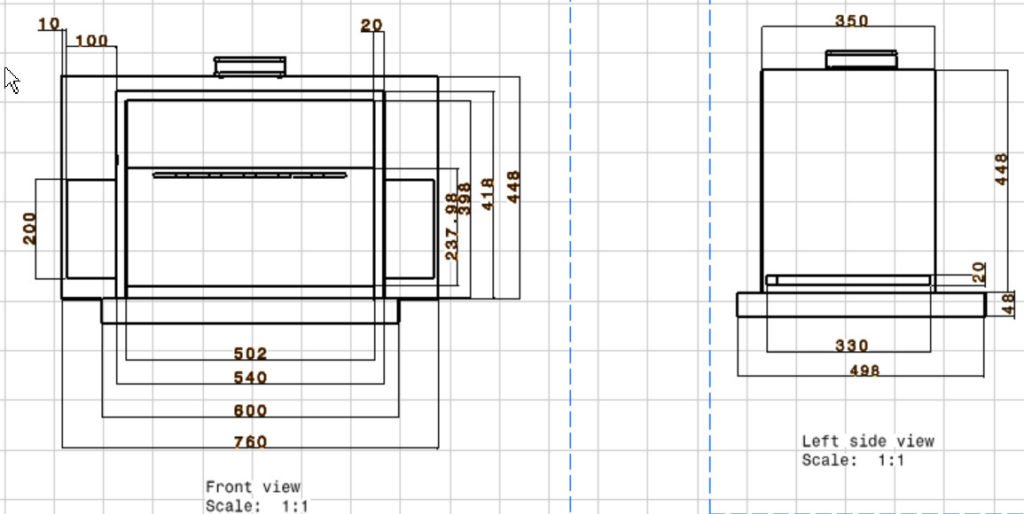

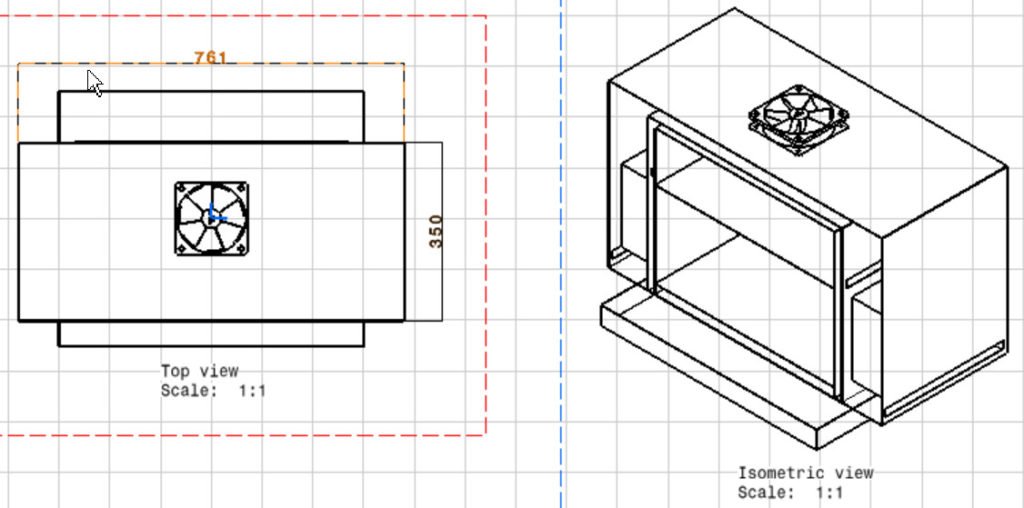

2D sketch of Evaporative cooling system:

Drafted model of Evaporative cooling system:

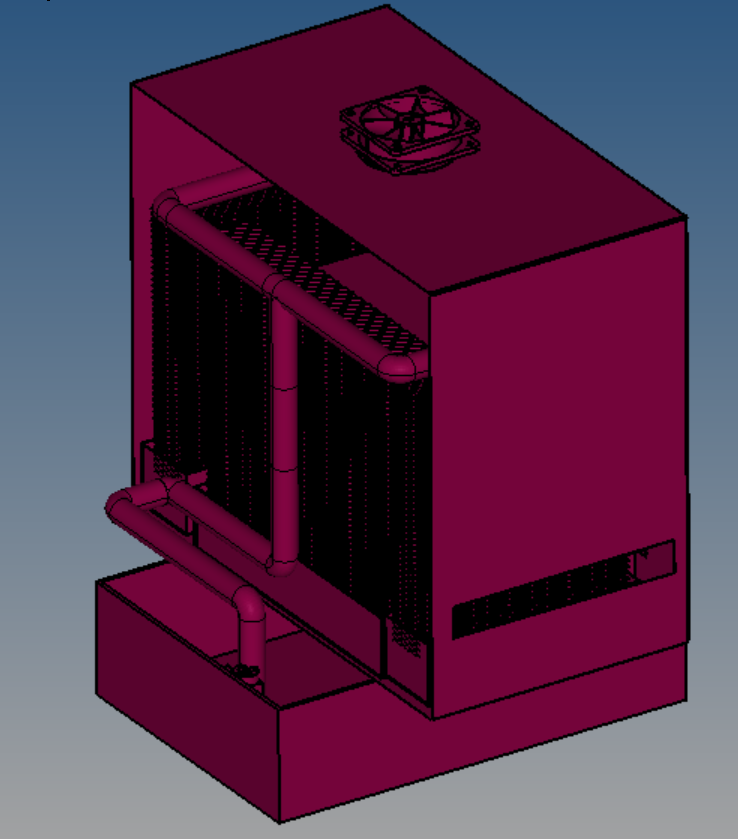

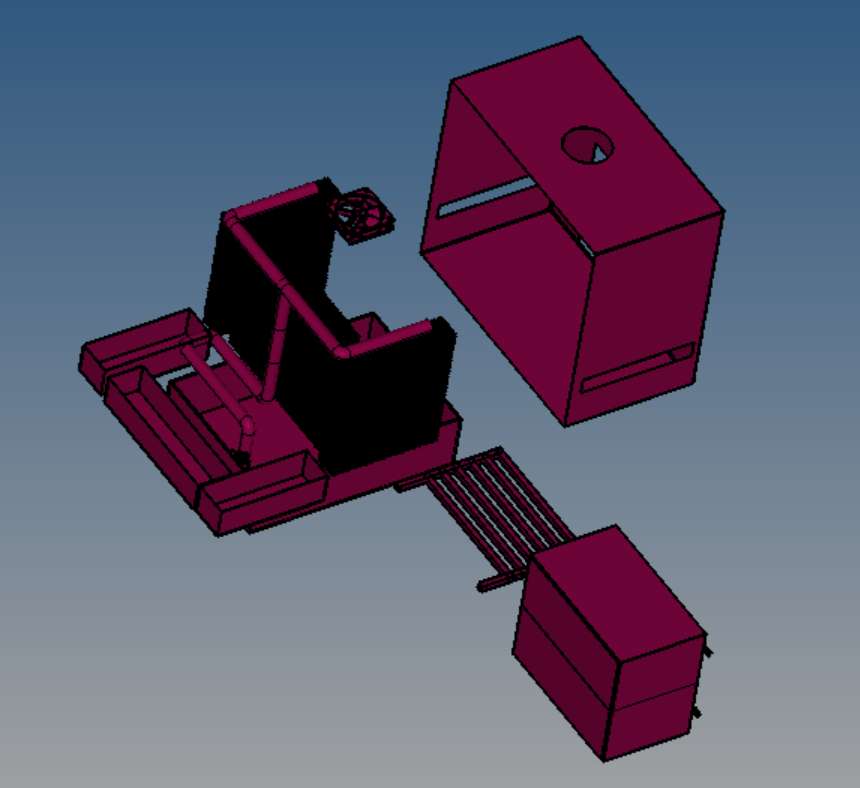

3D model of Evaporative cooling system:

Dimensions of cooling system: (all dimensions in ‘cm’)

Inside storage chamber: 50 X 30 X 40

cover of storage chamber: 54 X 32 X 42

outside jacket dimensions: 76 X 34 X 44

honeycomb pad dimension:30 X 10 X 20

water sump dimension: 60 X 50 X 10

Coil dimensions: length=3064 cm, diameter=1 cm

Capacity of storage chamber:

Inside storage chamber capacity= 50 liter.

Product description:

The Evaporative cooling product description given in below link.

CAD model:-

Exploid view of Evaporative system:-

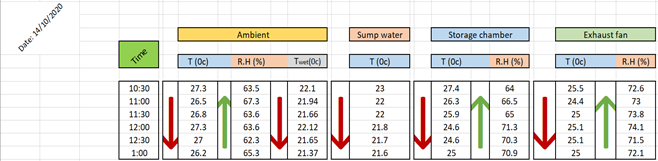

Trials Data:-

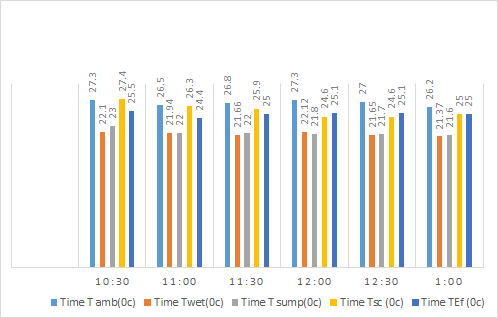

Temperature variation with respect to time in graphical way.:-

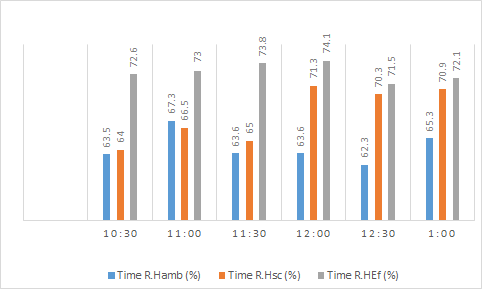

Relative humidity variation with respect to time in graphical way:-

conclusion:- Evaporative cooling unit prototype completed with discussed parameters