DESIGN AND FABRICATION OF TAMARIND DESEEDING MACHINE

Introduction

Tamarind plant is planted in the month of July. The tamarind on tree is mature at the month of December. The harvesting period of tamarind is from march to April. The one plant of Tamarind yields about 250-300 kg tamarind. The yield of tamarind per acre is about 8 to 10 tons.

Origin

Tamarindus indica is probably indigenous to tropical Africa,but has been cultivated for so long on the Indian subcontinent that it is sometimes reported to be indigenous there. It grows wild in Africa in locales as diverse as Sudan, Cameroon, Nigeria, Zambia and Tanzania. In Arabia, it is found growing wild in Oman, especially Dhofar, where it grows on the sea-facing slopes of mountains. It reached South Asia likely through human transportation and cultivation several thousand years BC. It is widely distributed throughout the tropical belt, from Africa to South Asia, northern Australia, and throughout Oceania, Southeast Asia, Taiwan and China.

In the 16th century, it was introduced to Mexico and Central America, and to a lesser degree to South America, by Spanish and Portuguese colonists, to the degree that it became a staple ingredient in the region’s cuisine.

Production

Seeds can be scarified or briefly boiled to enhance germination. They retain their germination capability for several months if kept dry.[citation needed]

The tamarind has long been naturalized in Indonesia, Malaysia, Sri Lanka, Philippines, the Caribbean, and the Pacific Islands. Thailand has the largest plantations of the ASEAN nations, followed by Indonesia, Myanmar, and the Philippines. In parts of Southeast Asia, tamarind is called asam.[27] It is cultivated all over India, especially in Maharashtra, Chhattisgarh, Karnataka, Telangana, Andhra Pradesh, and Tamil Nadu. Extensive tamarind orchards in India produce 275,500 tons (250,000 MT) annually.

Harvesting

Tamarind fruits mature in early summer. They may be left on the tree for as long as 6 months after maturity so that the moisture content will be reduced to 20% or lower. Fruits for immediate processing are often harvested by pulling the pod away from the stalk. The tree begins to bear fruit at the age of 13-14 years and continues to yield abundant crops for more than 60 years. The flowers appear from June and July and the pods ripen in the cold season. The pods should be allowed to ripen on the tree until the outer shell is dry.Mostly the harvesting of tamarind takes place between 1st March to 15th April. Fruits harvested by the pulling pod away from the stalk. The fruits harvested are stored in neat and clean place. The harvested pod should sun dried for getting best pulp. Fruit harvested after 15th April must be stored in refrigeration.

Products of tamarind

Pulp and Processed Products

1) Pulp:

2) Tamarind toffees :

3) Tamarind pulp powder:

4)Jam:

5) Tamarind pickle:

6) Syrup:

7) Candy:

8) Champoy:

9)Ade:

Deseeding

Methods of deseeding of tamarind

- Manually

- semi automatic machine

- Mechanically

Manually

Manual deseeding of tamarind is done by opening the tamarind seed cover with hand.

Semi automatic

The half operation of deseeding is done in machine in remaining half is done by operator. In this type of tamarind deseeding machine it is require to insert the tamarind in slot Manually

Mechanically

The complete operation of tamarind deseeding is done with the use of tamarind deseeding machine.

Problem definition

There is no small scale tamarind deseeding machine in market. Current available machine has issue of safety since it made to insert Tamarind manually. Current machine take more time for operation due to low efficiency. There is no appropriate solution for tamarind deseeding.

Objectives

- To study available deseeding solutions in market.

- To design and develop solutions for tamarind deseeding.

Literature Review :

Present Solutions For Deseeding Of Tamarind

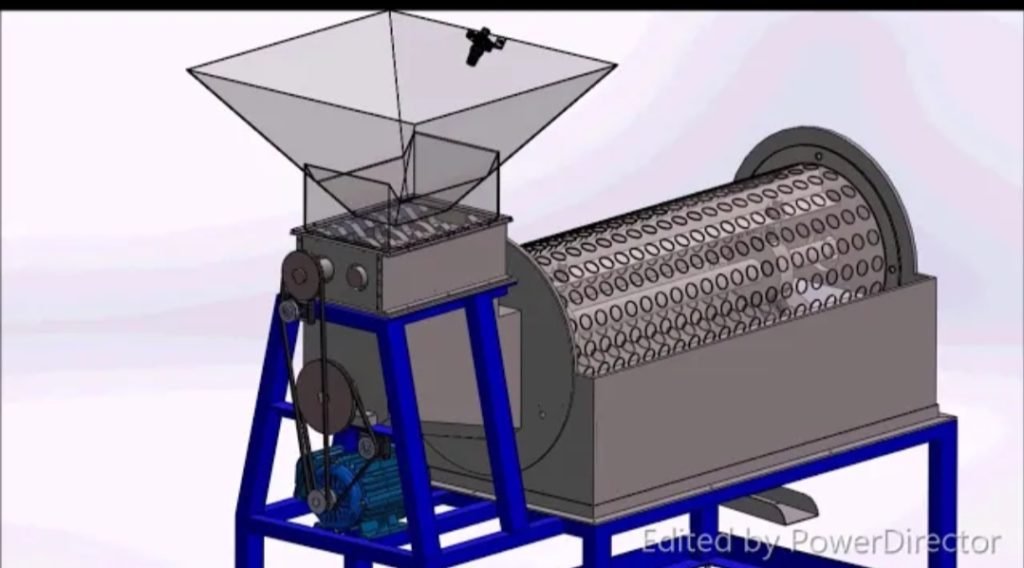

1)Threshing cylinders is used in this machine for tamarind deseeding. Due to this it has more breakage of tamarind seeds in the machine.

2)This machine extracts pulp of tamarind from tamarind which can be further processed and used. Most of tamarind pulp is remain as it is on seed.

Machine For Deseeding of Dates :

This machine is dates deseeding machine which breaks the seeds of dates and the seeds are further removed manually.

Research Papers :

• ParamasivanKarthickumar et al.( 2015 ) reported that tamarind deseeder was developed in this study. The performance evaluation of thedeseeder showed that fruit moisture content, material feed rate and machine speed had significant effect on its performance indices. The combination of feedrate 45 kg·h-1 with the wooden shaft of 3.4 m·s-1 and clearance of 16 mm to deseed the tamarind at the moisture content of 22.5% on dry basis as considered was the best among the eighty one different treatments tested in Agres package, since the maximum deseeding efficiency was obtained as 89.15%. The deseeder has a compact design and a robust outlook. It will contribute to the enhancement of tamarind processing as it could be used to eliminate the tediousness of the present traditional methods of tamarind deseedingPresentsolution for tamarind deseeder is available. The machine is available commercially on India mart.

• Ramaswamyet al.( 2015 )reported that the manual separation of the seeds is not only labour-intensive but is also suspect from the point of view of hygiene. “While only 3 kg can be separated per hour through manual operation, the device can handle 60 kg an hour,” he says.

• Shringareet al.( 2015 )reported that the completion of the project work we tried it in our college machine shop and we were pleased to note that it does meet the requirement for what it is meant. We conclude that the mechanism adopted in the Design and Fabrication of tamarind pulp separator machine is successful, because depending upon the climatic condition the performance can be improved. This machine reduces human effort as well as time involved in the manual operation of people so that improving their working method.

Commercial machine is available

https://www.indiamart.com/proddetail/tamarind-seed-separator-machine-19859434491.html

The available machine has high cost and low efficiency hence it is not possible to use at all the levels of deseeding.

Types Of Threshing Cylinder :

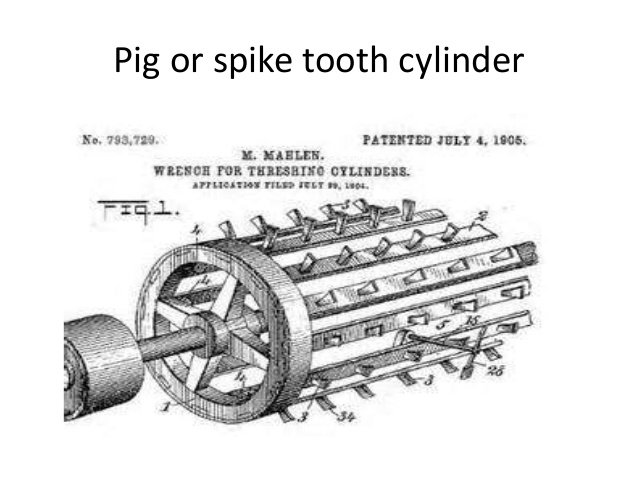

Spike tooth type cylinder: In this type of threshing drum, there is a hollow cylinder, made out of MS flat. Over to its entire periphery, a number of spikes/pegs of square /round bars or flat iron pieces are welded or bolted. Now days, in most of threshers, round peg with adjustable length are used. These spikes are staggered on the periphery of the drum for uniform threshing. The crop is fed along with the direction of motion of the rotating drum. The spike tooth cylinders are available in various sizes. A spike tooth cylinder with spikes of flat front and streamlined back has lower energy consumption.

Rasp bar type cylinder: In this type of cylinder, there are slotted plates, which are fitted over to the cylinder rings, in such a way that the direction of slot of one plate is opposite to another plate. This type of cylinder is commonly used in threshers. It gives better quality of bhusa and it can be used for a wide variety of crops viz.-wheat, paddy, maize, soybean etc.

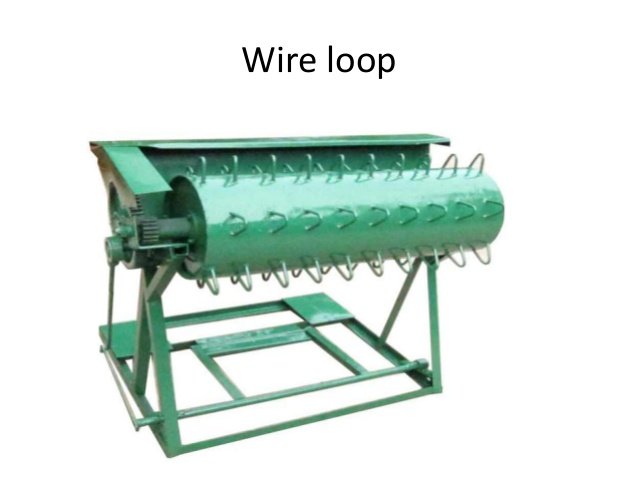

Wire loop type cylinder: In this type of threshing drum, there is hallow cylinder, over which a number of wooden or MS plates are fitted. On these plates, number of wire loops is fixed for threshing purposes. This type of cylinder is common in the manually operated paddy threshers. Holding the bundle against the loops of revolving cylinder does threshing of paddy crop.

Collection Of Tamarind From Field :

For collection of tamarind I was go to rajgurunagar Market but there is not availabality of tamarind in market so I get the tamarind from the field in rajgurunagar.

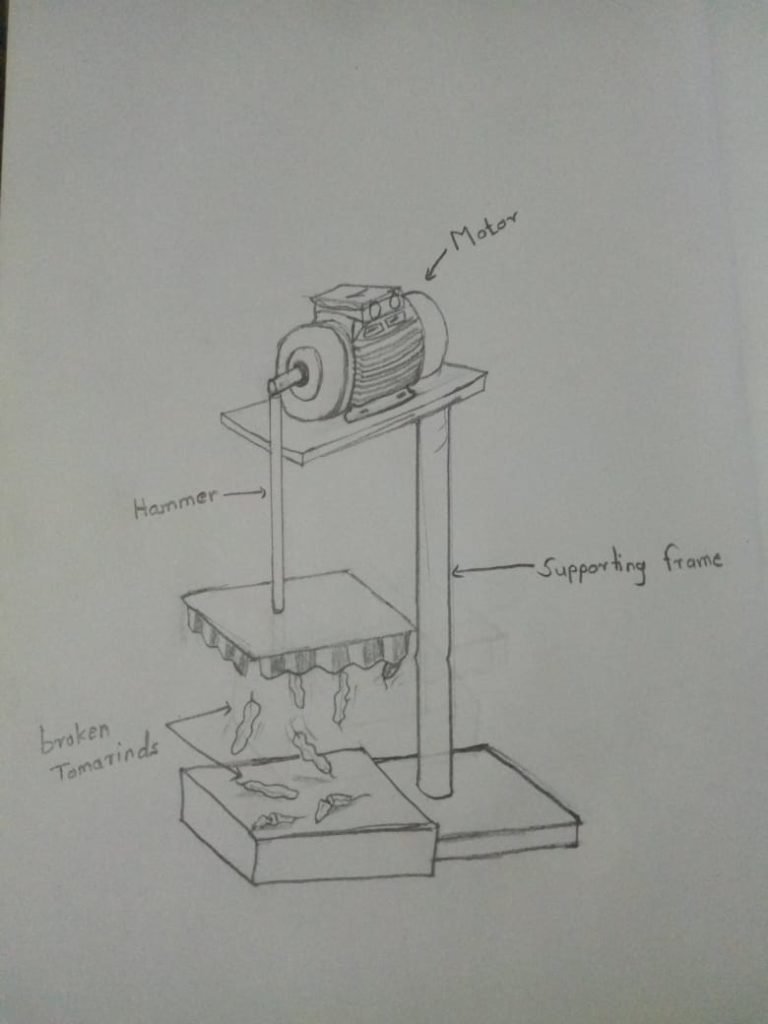

To check the effect of hammering on tamarind

Hammering On Tamarind ( Wet ) :

Hammering on tamarind with different positions is done to find out how the seeds are separated from tamarind With hammering.

Hammering On Edge Of Tamarind :

Hammering On Flat Surface Of Tamarind :

It has been observed that due to moisture in tamarind it is not easy to deseed tamarind. Then it has been decided to dry the tamarind in sun drying.

Hammering On Tamarind (Dry) :

Hammering On Edge Of Tamarind :

Hammering On Flat Surface Of Tamarind :

Conclusion

It has been observed that on flat surface tamarind deseeding is possible.

Hammering On Straight Placed Tamarind :

Surface Area Of Hammer : πr2

= 3.14 x 1.25 x 1.25

= 4.90 square cm.

Physical Characteristics Of Tamarind :

- Lenth : The fruit is an indehiscent legume, sometimes called a pod, 12 to 15 cm (4.7 to 5.9 in) in length, with a hard, brown shell. The fruit has a fleshy, juicy, acidic pulp. It is mature when the flesh is coloured brown or reddish brown.

- Width : Average width of tamarind is 2 to 2.5 cm.

- Thickness : Average thickness of tamarind is 1 cm.

- Distance between two seed : 8 to 10 mm.

Physical Characteristics Of Tamarind Seed :

- Lenth : 1.5 to 2 cm

- Width : 1 to 1.5 cm

- Thickness : 3 to 5 mm

Shear Strength Of Tamarind seed Cover Calculation :

Shear strength of tamarind seed cover is calculated to find out the force required to cut the tamarind seed cover.

Shear strength is calculated with use of knife and adding the weights to cut the tamarind seed cover.

Shear Strength : Force x Acceleration

= 5876 x 9.81

= 57643 N

Calculation Of Bulk Density Of Tamarind Pulp :

Bulk density is calculated to find out how much material is fit into the machine. Hence it helps to calculate efficiency of machine.

Bulk Density = Mass / Volume

= 32/20

= 1.6 g/cc

Free Falling Of Tamarind Through Hopper :

- With Less Input

- With More Input

Observation :

- With less input

Falling pattern Of tamarind is flat.

2.With more input

Falling pattern of tamarind is flat.

Free falling of tamarind through hopper is done to see the falling pattern when the tamarind is go below through hopper.

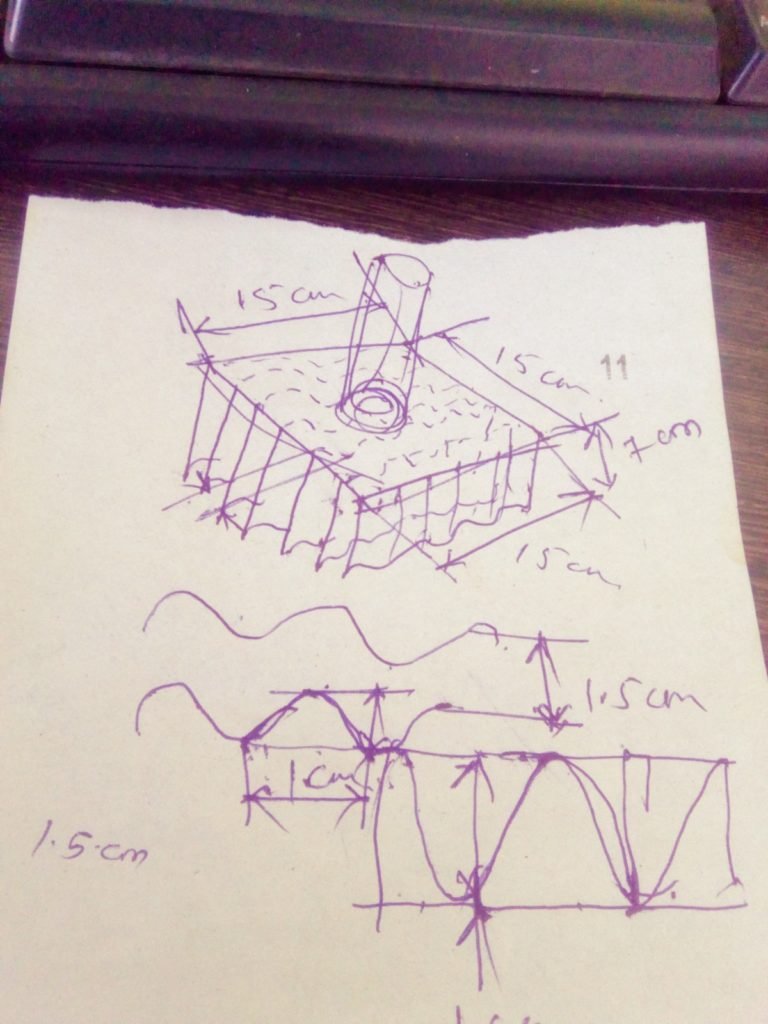

Fabrication OF Zigzag Hammer 1 :

It has decided that to fabricate zigzag hammer for deseeding of tamarind.

Inside this hammer the tamarind is placed flat in any pattern. The operation is performed same in all conditions as tamarind is fall inside the hammer in in any direction.

As the tamarind has curve shape there is no problem for deseeding inside this hammer. For this purpose it is decided to fabricate zigzag hammer.

Calculation Of Number Of Corrugations In The Length Of 15 cm :

= 15/1.57

= 9.5

Dimensions Of Zigzag Hammer : 15 x 15 cm.

There are 15 corrugations in 15 cm so for 1 corrugation of 1 cm 1.5 cm length of sheet is required

Therefore,

For 15 corrugations = 15 x 1.57

= 23 cm.

Reference : https://math.stackexchange.com/questions/1329840/corrugated-steel-sheet

Design Of Zigzag Hammer :

Cutting : Plasma cutting of metal sheet of 15 x 7 cm for fabrication of zigzag plates and for covering this plates metal sheet of 17 x 19 cm.

Cutting is done on CNC cutting machine.

CNC cutting machine

What do CNC Machines Do?

Once you understand how a CNC machine works, you’ll find that they can be utilized with machines and tools of all kinds.

CNC machines, or Computer Numerical Control machines, make use of computer systems and software programs to automate machinery, including quite complex and advanced operations. As such, a CNC cutting machine (also called a burn table) makes use of CNC processes to cut materials of all kinds including steel, aluminum and wood.

Hornet Cutting Systems has three core CNC cutting processes: CNC plasma cutting machines, CNC oxy-fuel cutting machines and CNC waterjet cutting machines.

CNC Plasma Cutting :

Our CNC plasma cutting machines cut up to 3″ mild steel, 4″ stainless steel and 3″ aluminum and are capable of producing both straight and bevel cuts. Our line of CNC plasma cutters are built to cut metal plates as well as metal pipes.

CNC Oxy-fuel Cutting :

Our CNC oxy-fuel cutting machines cut through mild steel, stainless steel as well as aluminum. Our line of CNC oxy-fuel cutting machines are capable of cutting metal plates as well as pipes.

CNC Waterjet Cutting :

Our waterjet cutting machine works with a highly pressurized jet of water, or a mixture of water and an abrasive. Our CNC waterjet cutting machine can cut materials ranging from wood to steel and produces no smoke.

Plasma cutting of metal sheet of 15 x 7 cm for fabrication of zigzag plates and for covering this plates metal sheet of 17 x 19 cm.

Bending : Metal sheet bending.

Bending of metal plates is done with hand operated Bending machine.

Hand operated Bending machine :

A bending machine is a forming machine tool(DIN 8586). Its purpose is to assemble a bend on a workpiece. A bend is manufactured by using a bending tool during a linear or rotating move. The detailed classification can be done with the help of the kinematics.

Universal bending machines consists of a basic machine that can be adjusted with little effort and used for a variety of bends. A simple plug-in system supports quick and easy exchange of tools.

Welding : Welding of bended sheets to the flat metal sheet.

welding is done with use of arc welding machine

Arc welding

Arc welding is a type of welding process using an electric arc to create heat to melt and join metals. A power supply creates an electric arc between a consumable or non-consumable electrode and the base material using either direct (DC) or alternating (AC) currents.

How Does it Work?

Arc welding is a fusion welding process used to join metals. An electric arc from an AC or DC power supply creates an intense heat of around 6500°F which melts the metal at the join between two work pieces.

The arc can be either manually or mechanically guided along the line of the join, while the electrode either simply carries the current or conducts the current and melts into the weld pool at the same time to supply filler metal to the join.

Because the metals react chemically to oxygen and nitrogen in the air when heated to high temperatures by the arc, a protective shielding gas or slag is used to minimise the contact of the molten metal with the air. Once cooled, the molten metals solidify to form a metallurgical bond.

Prototype 1

Perfomance Testing Of Zigzag Hammer :

It has been observed that the breaking of tamarind is done.alomst 25 percent of tamarind seed are broken. 95 percent seeds are removed by hammering with this hammer. Then the remaining thing is to separate seeds with giving of circular motion to this seeds.

Fabrication Of Zigzag Hammer 2 With Modifications :

It has been observed that the clearance between plates is more hence the operation is not performed correctly.

Then the clearance between plates and width of plates is adjusted as below

1. width of zigzag plates = 3 cm

2. Clearance between two plates = 1 cm

3. Thickness of metal sheet : 2.5 mm

Cutting :

Cutting of metal plates to reduce width from 7 cm to 3 cm is done with hand grinder.

Hand grinder

At the time of cutting plates with hand grinder it is require to wear safety tools like goggle, hand gloves.

Welding :

Testing :

percentage of breakage of tamarind seed is reduced to 20 percent.

Fabrication Of Zigzag Hammer 3 With Modifications :

In the second prototype it has been observed that the thickness of plates is more and it is not easy to bend.

Hence the plates of thickness 1.5 cm is selected.

1. width of zigzag plates = 3 cm

2. Clearance between two plates = 1 cm

3. Thickness of metal sheet : 1.5 mm

Cutting : cutting is done on CNC cutting machine :

Bending :

Bending all plates simultaneously so that the profile of hammer is matched perfectly.

Welding :

Testing :

Prototype 3

Fabrication Of Zigzag Hammer 4 ( Matching Profile Precisely ) :

In the third prototype it has been observed that the profile of hammer is not matched perfectly.

So that prototype 4 is fabricated with matching profile precisely.

Cutting : cutting is done on CNC cutting machine :

Bending :

Welding :

Testing :

Mechanization Of Zigzag Hammer :

1 ) How To Convert Rotary Motion TO Reciprocating Motion :

How To Calculate Force Of Impact :

https://sciencing.com/calculate-force-impact-7617983.html

Design of tamarind deseeding mechanism

It has been decided that to use slider crank mechanism to mechanise zigzag Hammer.

A CASE STUDY OF BREAKING SEED DORMANCY IN TAMARIND

The study was carried out to investigate the effects of sulphuric acid and hot water treatments on the germination of Tamarind (Tamarindus indica). Seeds were sown in poly pots under normal environmental condition for germination. Thirty (30) seeds of T. indica (one seed per pot) with ten replicates each

were used. The highest germination percentage was recorded in seeds treated with fifty (50%) percent sulphuric acid concentration within sixty (60) minutes soaking period. Germination was observed to be enhanced by the effect of sulphuric acid on disrupting the seed coats of Tamarind (Jabbe), followed by hot water. Results of this research may serve as useful information in the production and improvement of the tree species, as knowledge on seed germination requirements is a critical factor in seedlings production.

Result

The seeds of Tamarind is treated with sulphuric acid has Great germination percentage as compared to seed treated with hot water.

Plate No 4.2.22 T.indica seeds treated with Sulphuric acid of 50% concentration.

Plate No 4.2.23 T.indica seeds treated with hot water.

Reference

https://www.researchgate.net/publication/266327259_Breaking_Seed_Dormancy_in_Tamarind_Tamarindus_Indica_A_Case_Study_of_Gombe_Local_Government_Area