In India, the healing power of foods has long been regarded as important and Indian cuisine incorporates many medicinal elements. I doubt if our ancient Indian ancestors understood what bacteria are, but I imagine they had worked out that yogurt helped with digestion. We know now that this is because the bacteria that turn milk into yogurt also help fight infections in the intestine. In a hot country like India where stomach bugs were easy to pick up, yogurt acted as an ancient antibiotic. That was why it is rarely heated (heat kills bacteria) and is eaten it as close to room temperature as possible in most cases.

When working with Indian recipes you may find that curd and buttermilk are variations of yogurt.

Curd

Curd is such an important part of Indian meals, and traditions vary. If plain curd is served with a meal, in some parts it is eaten first, some with the meal and some eat it at the end of a meal. I really like it in the end, but if the meal is REALLY hot-spicy, it is wonderful to have the yogurt to balance the heat.

Curd can also be used as an ingredient in dessert and savory dishes. It may form the basis of a dish in its raw form, or it can be a component of a cooked dish.

The Chemical Process of Curd Making as Follows:

LAB(Lactic Acid Bacteria) + Lactose = Lactic Acid(Low PH)

In the environment, bacterial growth is tremendous in the temperature range of 15-45 Celcius.

Objectives of the Project:

- To maintain a temperature constant up to 3 hrs.

- To minimize heat losses .

- To make a product which consistence performance in all climatic condition.

Trial and Error method:

The main aim of this project is to make curd in 3 to 4 Hrs, Which is impossible in the conventional method. For achieving this result I find out the optimum temperature range and it is 40 to 45o C.

In this keep temperature constant for 3 to 4 Hrs, then the same function see in a thermos flask.

1] Frist trial:

Do the same procedure for curd making in-home, but I use here a thermos flask to maintain a temperature constant. After 3 hrs curd is ready and the temperature is drawn by 10o C.From above trial and error experiment I got one think curd made in 3 hrs by keeping the temperature constant. After that, I think about insulation materials.

2] Second trial :

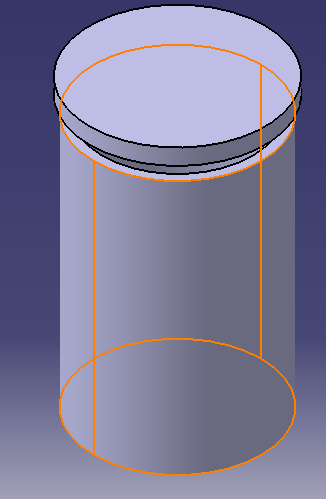

In this experiment take stainless steel tin with insulation over on it. The specification is:

- Length: 15 cm

- Width: 9.5 cm

- Circumference: 10 cm

- Insulator width: 0.4 cm

The same procedure carries out, then the result is the same as that of the previous experiment.

3] Third trial:

As per the cost reduction factor, we use simple hand made bag in which heatlon was used as insulated material and outer was cotton. In this bag bottom side is closed and upper side fitted a chain opening for inserting a curd container.

4] Fourth trial:

In previous trial we achieve better results, but aesthetic view is not good and also functionality point of view is poor, so this drawbacks fulfilled in fourth trial.

Design of tin

Advantages of curd maker:

- Curd maker equipment is simple to use and low price, which is use to everyone.

- Curd is ready in 3-4 Hours for eating.

- This equipment should aesthetically and functionally good.

- Tasty and best quality curd.