INTRODUCTION

Hardness is an indication of the amount of calcium and magnesium in the water. Hard water is due to the presence of calcium and magnesium and is formed when water passes through or over limestone or chalk areas and calcium and magnesium ions dissolve into the water. Hardness is given in terms of the equivalent quantity of calcium carbonate (CaCO3) in milligrams per liter (mg/L) or parts per million (PPM).Calcium and Magnesium are essential elements for plant growth that are reported in parts of element per million parts water (ppm) on a weight basis. Calcium in the range of 40 – 100 ppm, and magnesium in the range of 30 – 50 ppm are considered desirable for irrigation water.

Total Dissolved Solids (TDS) is a measure of the dissolved combined content of all inorganic and organic substances present in a liquid in Atomic, ionized or micro-granular (colloidal sol) suspended form. Total dissolved solids are normally discussed only for freshwater systems, as salinity includes some of the ions constituting the definition of TDS. The principal application of TDS is in the study of water quality for streams, rivers and lakes, although TDS is not generally considered a primary pollutant (e.g. it is not deemed to be associated with health effects) it is used as an indication of aesthetic characteristics of drinking water and as an aggregate indicator of the presence of a broad array of chemical contaminants.

Lime softening, also known as Clark’s process, is a type of water treatment used for water softening which uses the addition of limewater (calcium hydroxide) to remove hardness(calcium and magnesium) ions by precipitation.

Lime softening was first used in 1841 to treat Thames River water. The process expanded in use as the bactericidal effect of the process was discovered. Lime softening greatly expanded in use during the early 1900s as industrial water use expanded. Lime softening provides soft water that can, in some cases, be used more effectively for heat transfer and various other industrial uses.

As lime in the form of limewater is added to raw water, the pH is raised and the equilibrium of carbonate species in the water is shifted. Dissolved carbon dioxide (CO2) is changed into bicarbonate and then carbonate. This action causes calcium carbonate to precipitate due to exceeding the solubility product. Additionally, magnesium can be precipitated as magnesium hydroxide in a double displacement reaction.

In the process both the calcium (and to an extent magnesium) in the raw water as well as the calcium added with the lime are precipitated. This is in contrast to ion exchange softening where sodium is exchanged for calcium and magnesium ions. In lime softening, there is a substantial reduction in total dissolved solids (TDS) whereas in ion exchange softening, there is no significant change in the level of TDS .Lime softening can also be used to remove iron, manganese, radium and arsenic from water.

OBJECTIVE:

- To convert hard water into soft water of the Pabal village and make it drinkable.

- To reduce the clogging problem in drip irrigation system.

PROBLEM DEFINITION

In the Pabal village the TDS of the drinking water is about 450 ppm which is high than WHO guidelines. Abnormally high TDS in water is a problem, drinking of which will cause health issues. It becomes harmful only when it exceeds certain acceptable limit which was seen in that case. In fact, the TDS concentration is more of an aesthetic hazard as compared to a health hazard because it is secondary drinking water standard.

High concentration of TDS can cause water to become corrosive, salty or develop a brackish taste. This result in formation of scales in pipes, appliances like water heater and washing machines thereby reduce their efficiency. Because of all of this we need to reduce the level of TDS from water. IDEA

There are a number of methods to remove the hardness present in water. One those methods are being followed; the hard water gets converted to soft water. Some of the methods to remove hardness from water are,

- Chemical process of boiling hard water.

- Adding slaked lime (Clark’s Process).

- Adding washing soda.

- Reverse osmosis.

- Calgon process.

- Ion exchange process using ion exchange resins.

In this among reverse osmosis is one of common procedure which were used for reducing TDS level in water but it is very costly. The Lime Softening is one of the cheapest methods to reduce the TDS of water and make it drinkable.

METHODOLOGY

Effect of Hardness in Water:

- The health effects of hard water are mainly due to the effects of the salts dissolved in it, primarily calcium and magnesium.

- It will cause build up of lime scale in pipes causing reduced flow and cause pipes to need to be replaced.

- Calcium salts, particularly calcium carbonates, precipitate out as a white film or plating in the system which was seen in the boiler.

Methodology Followed:

- Decided to vary the sample size for experimentation starting from 1 liter to 1000 liters.

- Variation of amount of calcium hydroxide was 2nd parameter in experimental plan

Two different methods manual and automated were tried. - The various parameters such as TDS, salt & pH electric conductivity were checked to verify effectiveness of process applied.

- The precipitate formed was removed by either filtration or sedimentation.

- Calcium oxide was tried in order to get cost beefiness.

Some Chemical Reactions:

The reactions involved in lime treatment process are as follows:

CaCO3 —-Heat——-> CaO + CO2

CaO + H2O ———> Ca(OH)2

CO2 + Ca(OH)2 ———> CaCO3 + 2H2O

Ca(HCO3)2 + Ca(OH)2 ———-> 2CaCO3 + 2H2O

Observations:

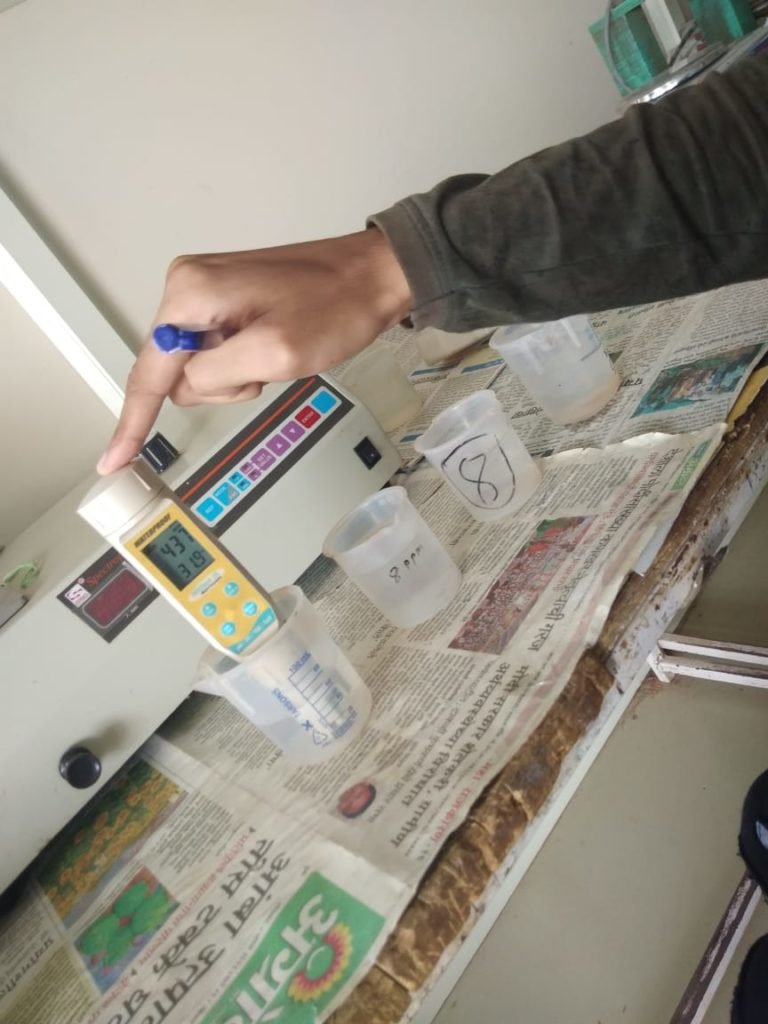

1] Firstly I took various samples of water from vigyan ashram and measured its different parameters such as TDS, Salt, pH and Electrical Conductivity, as follows:

| Water Samples | Salt (ppm) | pH (Nagarjun) | TDS (ppm) | EC (MicroSimens) |

| Filter water from kitchen | 333 | 7.45 | 437 | 631 |

| Tap water from kitchen | 328 | 7.96 | 437 | 617 |

| Tap water from hostel | 257 | 8.26 | 347 | 490 |

| Dreamhouse | 323 | 8.16 | 433 | 323 |

SOME CHEMICAL REACTIONS :

The reactions involved in lime treatment process are as follows:

CaCO3 —-Heat——-> CaO + CO2

CaO + H2O———> Ca(OH)2

CO2 + Ca(OH)2 ———> CaCO3 + 2H2O

Ca(HCO3)2 + Ca(OH)2 ———-> 2CaCO3 + 2H2O

OBSERVATIONS THROUGH TRIALS :

DATE : 04/06/2019 TRIAL NO.01:A

Adding 0.5 gm calcium hydroxide

Ca(OH)2 solution to 1 litre capacity water sample on shaking interval of 5 minutes for a period of 5hrs duration following obervations were obtained:

| Sample: Filter water from kitchen | Salt (ppm) | pH | TDS (ppm) | EC (μS) |

| Initial readings | 333 | 7.45 | 437 | 631 |

| Final readings | 212 | 7.60 | 219 | 406 |

DATE : 05/06/2019 TRIAL NO.02:

Adding 10gm calcium hydroxide

Ca(OH)2 solution to 20 litre capacity bucket and maintaining a shaking and stabling operation, for fulfilment of this process two water pumps were used for shaking purpose. And thus following observations were made:

| Sample: Drinking water from dreamhouse | Salt (ppm) | pH | TDS (ppm) |

| Initial readings | 323 | 8.16 | 433 |

| Time | Shaking period | Salt (ppm) | pH | TDS (ppm) |

| 12:00 PM | — | 323 | 8.16 | 433 |

| 1:00 PM | 1 hr | 213 | 9 | 287 |

| 2:00 PM | 10 min | 212 | 8 | 287 |

| 3:00 PM | 10 min | 212 | 8 | 287 |

| 4:00 PM | 20 min | 212 | 8 | 287 |

| 5:00 PM | 30 min | 212 | 8 | 286 |

DATE : 06/06/2019 TRIAL NO : 03

Adding 60 gm calcium hydroxide

Ca(OH)2 solution to 100 litre capacity water tank and mixing it with the use of two pumps and maintaining a shaking operation we derived the following results:

| Sample: Tap water from microbiology lab | Salt (ppm) | pH | TDS (ppm) |

| Initial readings | 310 | 9 | 417 |

| Time | Shaking period | Salt (ppm) | pH | TDS (ppm) |

| 4:00 PM | — | 310 | 9 | 417 |

| 5:00 PM | 30 min | 217 | 11 | 294 |

| 6:00 PM | 30 min | 214 | 10 | 284 |

| Next Morning 8:00 AM | — | 212 | 9 | 284 |

| 9:00 AM | 30 min | 204 | 10 | 277 |

| 10:00 AM | 30 min | 207 | 10 | 273 |

DATE : 08/09/2019 TRIAL NO : 04

Adding 250 gm calcium hydroxide

Ca(OH)2 solution to 500 litre capacity water tank and mixing it with the use of two pumps we derived the following results:

| Sample: Bore water infront of meeting hall | Salt (ppm) | pH | TDS (ppm) |

| Initial readings | 352 | 8 | 474 |

| Time | Shaking period | Salt (ppm) | pH | TDS (ppm) |

| 9:30 AM | — | 352 | 8 | 474 |

| 10:30 AM | 1 hr | 258 | 8 | 348 |

| 11:30 AM | 1 hr | 257 | 8 | 347 |

| 12:30 AM | 1 hr | 257 | 8 | 347 |

From the above observation the result obtained was not satisfactory as the TDS was not reduced to a considerable extent. so for purpose to be accompolised it was necessary to know the mixing patterns of solids in water.

For knowing the mixing patterns and time required for mixing I decided to know the electrical conductivity from diagonal regions of the water tank by treating the tank water with NaCl ( sodium chloride)

Procedure for knowing electrical conductivity of water :

- Preparation of sodium chloride solution of quantity 250 gm.

- Measuring the initial electrical conductivity of water by EC meter.

- Arranging the two submersible pumps in same allignment at the bottom of the water tank which are opposite in direction.

- Injecting sodium chloride solution (Nacl) at the middle bottom portion of the tank.

- Switching on the pumps and taking readings at a certain time interval and thereby taking the readings

Observation Table : 01

| Initial EC of water composed of Ca(OH)2 in it : | EC (μS ) : 495 |

After injecting Nacl at the bottom of the tank and turning on the motors following EC readings were made:

After 2 minutes mixing:

| Diagonal portions of water at the top surface | EC (μS ) |

| 1 | 589 |

| 2 | 502 |

| 3 | 503 |

| 4 | 1941 |

| 5 | 923 |

| 6 | 1135 |

After 8 minutes mixing:

| Diagonal portions of water at the top surface | EC (μS ) |

| 1 | 1364 |

| 2 | 1303 |

| 3 | 1296 |

| 4 | 1349 |

| 5 | 1251 |

| 6 | 1235 |

After 15 minutes mixing and measuring EC from middle portion of tank by using burette :

| Diagonal portions of water below 10 cm of surface | EC (μS ) |

| A | 1237 |

| B | 1295 |

| C | 1241 |

After 25 minutes mixing :

| Diagonal portions of water at the top surface | EC (μS) |

| 1 | 1281 |

| 3 | 1281 |

| 6 | 1281 |

Thus it was concluded that about 25 minutes are required for entire mixing of NaCl solution in the water tank of capacity 500 litre while keeping the pumps just opposite to each other at the bottom of tank.

Procedure II :

1. Preparation of sodium chloride solution of quantity 250 gm.

2. Measuring the initial electrical conductivity of water by EC meter.

3. Arranging the two submersible pumps one at the centre and other at the bottom of the tank.

4. Injecting sodium chloride solution (Nacl) at the middle bottom portion of the tank.

5. Switching on the pumps and taking readings at a certain time interval and thereby taking the readings.

Observation Table : 02

After 2 minutes mixing :

| Diagonal portions of water at the top surface | EC (μS) |

| 1. | 1298 |

| 2. | 1304 |

| 3. | 1293 |

| 4. | 1300 |

| 5. | 1295 |

| 6. | 1298 |

After 8 minutes mixing :

| Diagonal portions of water at the top surface | EC (mS) |

| 1 | 2.09 |

| 2 | 2.15 |

| 3 | 2.07 |

| 4 | 2.18 |

| 5 | 2.30 |

| 6 | 2.30 |

After 15 minutes mixing:

| Diagonal portions of water at the top surface | EC (mS) |

| 1 | 2.29 |

| 2 | 2.31 |

| 3 | 2.31 |

| 4 | 2.32 |

| 5 | 2.33 |

| 6 | 2.20 |

After 20 minutes mixing:

| Diagonal portions of water at the top surface | EC (mS) |

| 1 | 2.35 |

| 3 | 2.35 |

| 6 | 2.35 |

Thus analyzing this above observation tables, it took approximately 25 minutes for procedure I & 20 minutes for procedure II for complete mixing of NaCl solution in 500 litre capacity water tank.

Also I came to know the arrangement of pumps which need to be arranged while performing the mixing operation of solid to liquid (i.e Ca(OH)2 in raw water) keeping in contrast the above observations.

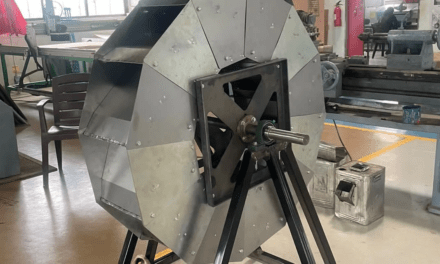

Thus, as per the ideology of mixing of Ca(OH)2 in water it is not possible at a short span of 20 minutes for overall mixing of it in water so I planned for designing baffles and placing them in the water tank. baffles are basically an obstruction for flow of water which creates a wide turbulence in water this will generate co-currents in the water leading to proper mixing.

Procedure for designing baffles:

- Took 80 cm length and 40 cm wide GI (galvanized iron) sheet of 1 mm thickness.

- Performed cutting operation of the sheet using cutter.

- Bending the sheets at an angle of 90 degrees using bending machine.

- Placed the two symmetrically alike baffle sheets in vertically opposite directions in the water tank which were fixed by wooden rods.

- Two pumps both of 18 watts power were fixed on the wooden rods at opposite directions.

- Operation of manufacturing baffles was performed in workshop while the water tank for performing mixing operation was placed in dreamhouse.

DATE : 26/06/2019 TRIAL 04 (B) :

Addition of 250 gm Ca(OH)2 in 500 litre capacity water tank and shaking it following observations were made.

| Time | Shaking period | Salt (ppm) | pH | TDS (ppm) |

| 9:45 am | — | 352 | 8 | 474 |

| 9:55 am | 5 min | 240 | 8 | 430 |

| 10:00 am | 5 min | 245 | 8 | 400 |

| 10:05 am | 5 min | 248 | 8 | 397 |

| 10:10 am | 5 min | 251 | 8 | 395 |

| Increasing the shaking period | ||||

| 10:30 am | 15 min | 264 | 8 | 365 |

| 10:45 am | 15 min | 264 | 8 | 358 |

| 11:00 am | 15 min | 251 | 8 | 356 |

| 11:15 am | 15 min | 242 | 8 | 340 |

| 11:30 am | 15 min | 219 | 8 | 298 |

| Increasing the shaking period | ||||

| 12:00 pm | 30 min | 213 | 8 | 288 |

| 12:30 pm | 30 min | 206 | 8 | 279 |

| 01:00 pm | 30 min | 205 | 8 | 277 |

| 01:30 pm | 30 min | 205 | 8 | 275 |

| 02:00 pm | 30 min | 205 | 8 | 273 |

Thus it took approximately 3 hours and 20 minutes for reducing the TDS and bringing it on a safe range for drinking.

Study Effect of Amount of Ca(OH)2 Used.

Following experiments were carried to study effect of amount of Ca(OH)2 used.

Calcium hydroxide is available as slimy paste and hence it was necessary to know the solid content. Loss on draying (LOD) was done as standard practice of keeping sample in oven at 110o C till constant weight.

Weight of samples with respect to time

| Time in Min | Weight of Sample |

| 0 | 1.002 |

| 30 | 0.406 |

| 45 | 0.395 |

| 50 | 0.392 |

| 55 | 0.394 |

% LOD OF CALCIUM HYDROXIDE = 100 (initial wt- final wt)/ initial wt

= (1.2002-0.394)*100/1.002

= 60.6 %

Hence solid content of Calcium hydroxide paste used was 39.4 %

CALCULATIONS

How much amount of calcium hydroxide or calcium oxide needed to add in high TDS water to reduce its TDS?

Firstly we need to know Atomic weight of calcium bicarbonate and calcium hydroxide or calcium oxide. They are as follows:

Atomic weight of calcium = 40

Atomic weight of oxygen = 16

Atomic weight of hydrogen = 1

Atomic weight of carbon = 12

Therefore,

Atomic weight of calcium hydroxide i.e. Ca(OH)2 = 74

Atomic weight of calcium bicarbonate i.e. Ca(HCO3)2 = 163

Atomic weight of calcium oxide i.e. CaO = 56

If the TDS of water is 467 ppm then,

Ca(OH)2 Ca(HCO3)2

74 163

? 467

Then by using cross multiplication, i.e. 74 X 467 = 163 X ?

? = 213.3

In 100 gm of Ca(OH)2 there is 60 % water and 40 % solid material

Therefore, 213.3 / 0.4 = 578.25

From this we conclude that approx 0.5 gm Ca(OH)2 need to add in 1 liter of water sample having TDS 467 ppm .

By the same way we can do calculation for the calcium oxide but in that case there is 100 % solid material.

CONCLUSIONS:

- As the tank capacity increases a gradual more turbulence is needed for proper mixing of the calcium hydroxide solution which must be satisfied by arrangement of baffles.

- The baffles where so arranged that the hydrostatic flow from the two submersible pumps will get obstructed and thus a substaintial turbulence will be thus created causing a efficient mixing of cacium hydroxide solution in water.

- General guidelines for classification of waters are: 0 to 60 mg/L (milligrams per liter) as calcium carbonate is classified as soft; 61 to 120 mg/L as moderately hard; 121 to 180 mg/L as hard; and more than 180 mg/L as very hard

- In my final experiment on 500 liter water tank the TDS of water was considerably reduced to 272 ppm & for calculating the amount of Ca+ ions present in that water I used spectrophotometer.

- As the solution of calcium hydroxide Ca(OH)2 is partially solubal in water the oxides of it reacts with bicarbonates of them in raw water thus a thin precipitates is formed and after a period of mixing and stabling operation the precipitate settles down at the buttom of the tank.

- Thus this precipitate needs to be filtered out and the filtered water should be used for drinking purpose.

.