INTRODUCTION

26/02/2025

The chili dome dryer refers to a type of solar dryer specifically designed for chilies’ and other agricultural products. The primary goal is to efficiently and hygienically dry chilies’, preserving their quality, color, and nutritional value. This method helps extend the shelf life of chilies’ reducing spoilage and wastes.

Improved product quality compared to traditional sun drying, which can lead to contamination and uneven drying. Beneficial for small scale farmers and food processing industries.

26/02/2025

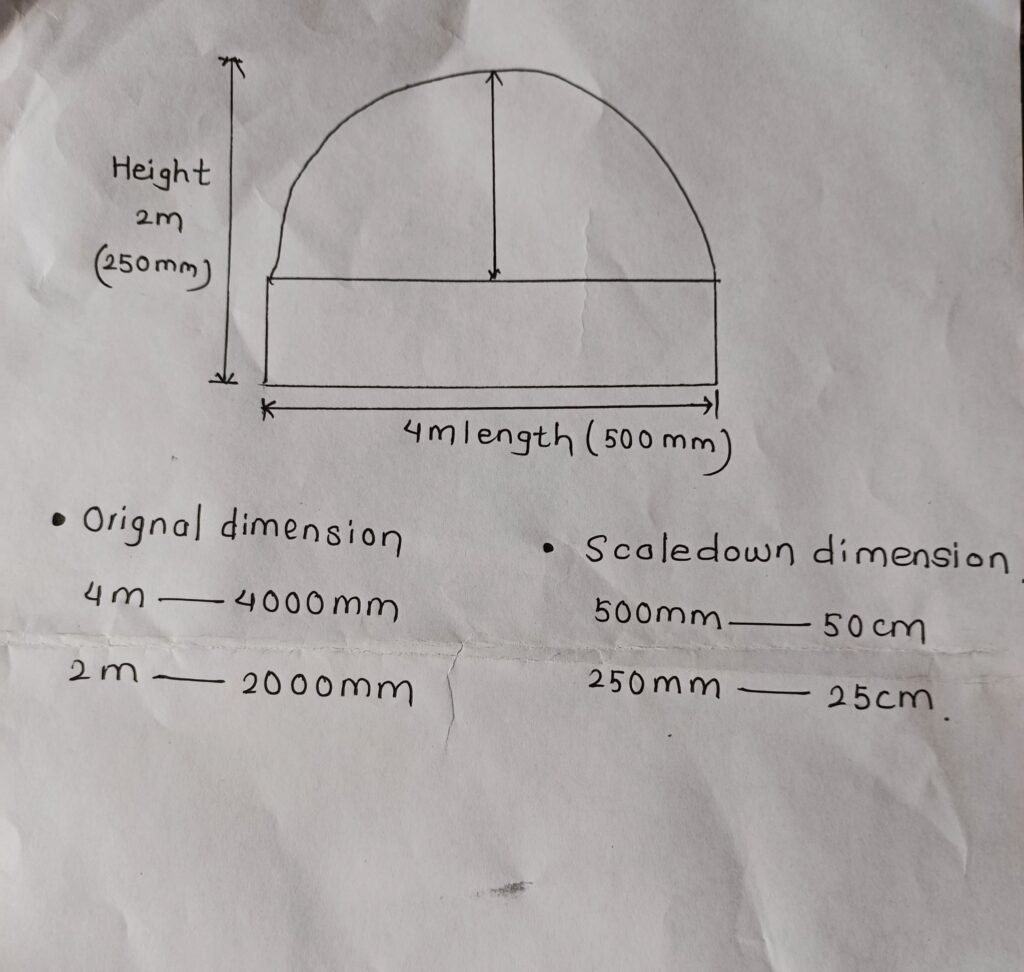

As discussed in the meeting regarding the solar dome dryer project, we have designed a scaled-down model for demonstration and testing purposes. The model is an eighth of the size of the original full-scale design, maintaining the same proportions and overall structure. This smaller version will help us evaluate the design’s functionality, efficiency, and feasibility before proceeding with the construction of the full-scale unit.

27/02/2025

We are determining the scaled-down dimensions. The original solar dome dryer was 4 meters, and we scaled it down to 45 centimeters.

28/02/2025

After meeting with Prasad Sir, we divided the solar dome dryer into three parts. The dome part was assigned to me.

01/03/2025

After meeting with Prasad Sir, we began working on the 3D printing model.

- Designing the Model

- Slicing the Model

- Preparing the Printer

- Printing the Model

- Post-Processing

02/03/2025

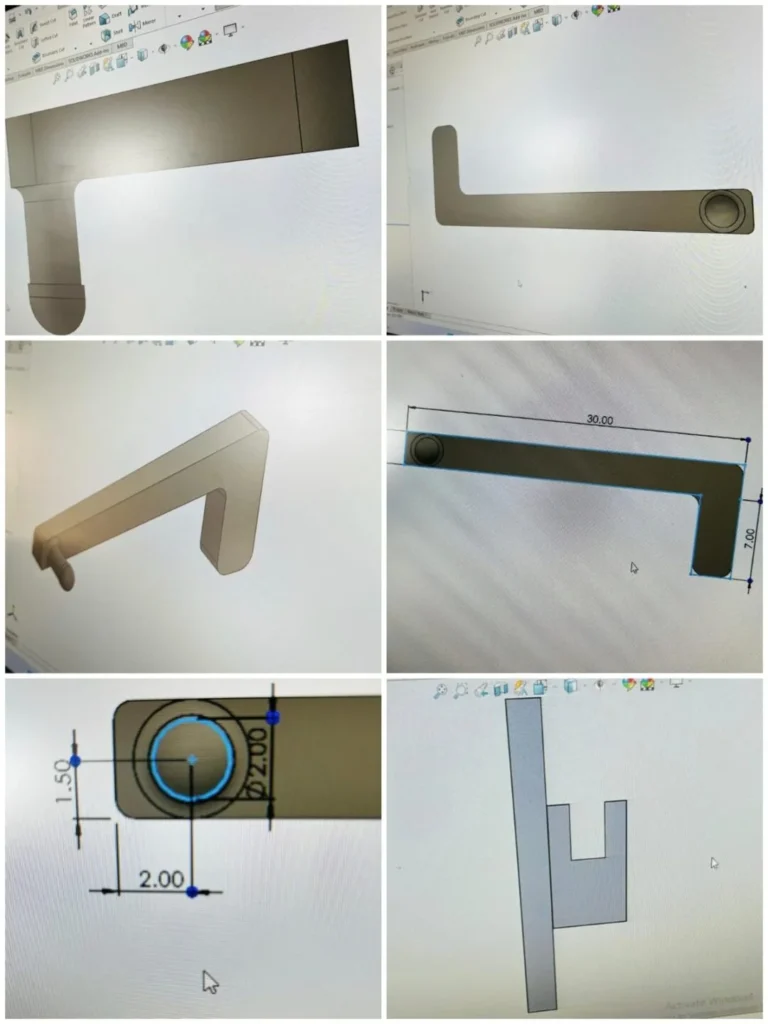

We focused on refining 3D designs using Solid works.

03/03/2025

We continue to learn our 3D design on the solid works.

04/03/2025

We continue our design tutorial on solid works.

05/03/2025

We start to work on dome part on solid works.

06/03/2025

We continue dome design on solid works.

07/03/2025

After meeting with Prasad sir we meet to Dipali maam for learn the 3D printing and leaser cutter.

08/03/2025

We again continue to our solid works design.

12/03/2025

After discussing with prasad sir we meeting to Dipali maam to print that design.

Conclusion:

Prasad Sir advised us to bring the project to a close due to multiple factors. One major issue was the shortage of filament—the material we had on hand wasn’t enough to complete the project as planned. Additionally, the 3D printing process itself was projected to take approximately four days, which was not feasible within our timeline. Considering these limitations, the decision was made to end the project in order to better utilize our time and resources.

04/05/2025

I started by sketching the actuator with a pencil, then made the engineering drawing, and finally designed it in SolidWorks.