At Vigyan Ashram, we have around 60 DBRT students who are always on campus, about 10 staff members, and 5-6 DIC students along with some DIC interns. Every day, our kitchen staff (Mausi) makes rotis by hand twice—once in the afternoon and again at night. This process requires a lot of time and effort.

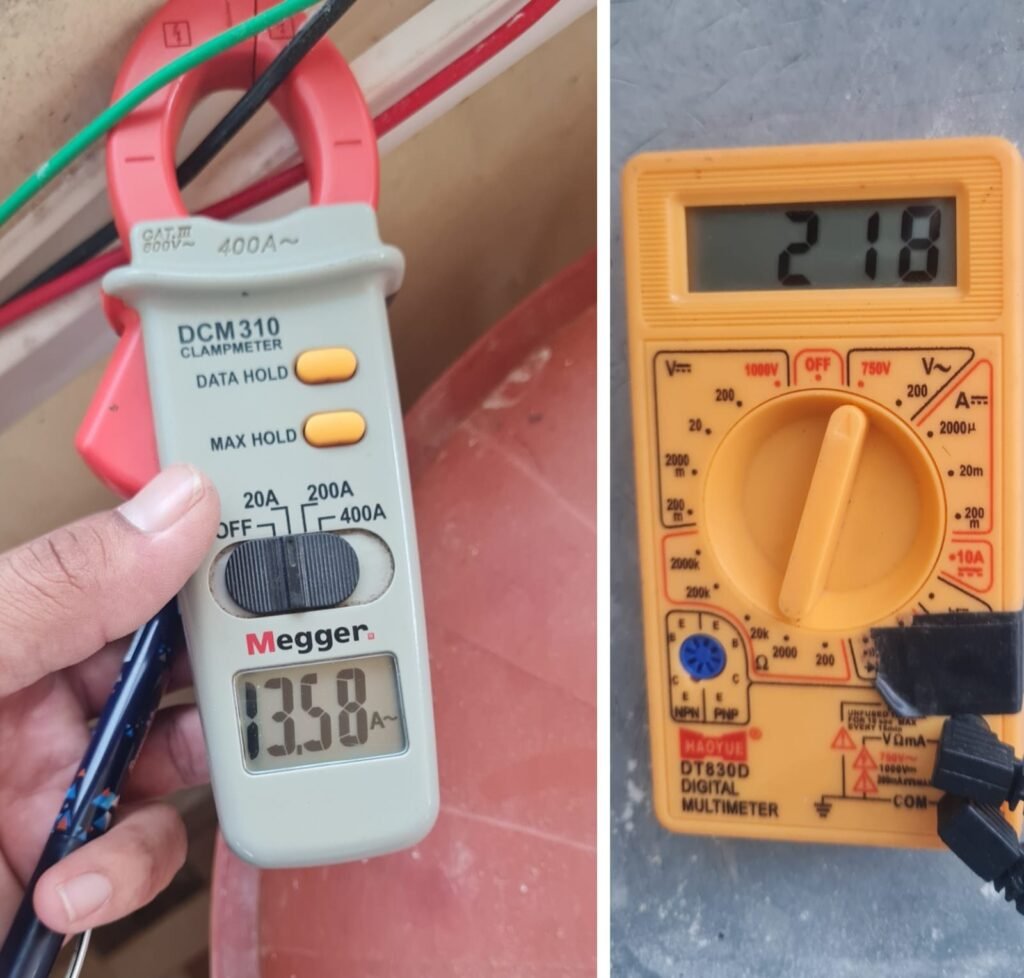

To ease this workload, Vigyan Ashram purchased a roti-making machine for ₹1.88 lakh. Dr. Dixit Sir asked me to review the cost effectiveness of this machine. To do so, I collected performance data during the afternoon over several days.

Below are the details –

If we use an automatic roti making machine, we can calculate the cost per roti. The both yellow rows shows cost per roti in automatic roti making machine and traditional roti making. Additionally, roti made in the machine lose nutritional value when exposed to sudden high temperatures, whereas traditionally made chapatis retain more nutrients.

When chapatis are cooked using an LPG-powered automatic machine, there is a possibility of incomplete combustion of LPG. In such cases, unburnt LPG residues or combustion byproducts like carbon deposits may stick to the chapati’s surface. This can not only alter the taste and smell of the chapati but may also introduce harmful chemicals. Prolonged consumption of food exposed to unburnt LPG residues could pose health risks, as incomplete combustion can release carbon monoxide and other potentially hazardous compounds.

• Rotimaker offers convenience but at a high cost.

• Health risks and nutritional drawbacks.

• Suggest exploring energy-efficient alternatives or optimizing traditional methods.