Chrysanthemum is a plant that has very less water requirement and is very sensitive to the amount of exposure of light it receives. According to a study by NASA chrysanthemum helps in reducing indoor polution. Chrysanthemum is a plant that flowers in winter and commercially has second largest market in the world. It has great variety and is asthetically very beautiful flowers thus it got selected as our plant for indoor hydroponics setup.

- OBJECTIVES :

- To convert already existing Deep Water Culture(DWC) system into flood and drain system.

- To study whether chrysanthemum can grow in a flood and drain system in indoors with help of LED light exposure.

- Our Existing DWC System :

- Convert DWC system to Flood & Drain system – WHY ?

Planting chrysanthemum in hydroponics system was a new concept for us. We didnt had firm data for a suitable system for chrysanthemum. So in a discussion with Dr. Arun Dixit sir it was decided that we will plant chrysanthemum in all three hydroponics system i.e NFT, DWC and F&D system. This DWC system was already available in DIC lab so it was decided to convert this system into flood and drain system.

- WHY FLOOD AND DRAIN ?

- In flood and drain system water is filled in the vessel till a height where net pot is fully deeped in the solution, the moment this happens pump stops and water is drained out of the vessel back into reservoir.

- Shevanti plant needs to be watered frequently as they loose moisture but it also has soil requirement which has good texture and is well-draining in nature. This condition is well provided by the flood and drain system, by using this system the roots of plant won”t be continuously exposed to water.

- COMPONENTS USED :

- Drip Pipes

- L-bows

- Submersible water pump(specifications- voltage: 165-220/50Hz, power:19W)

- Air pump

- Air stone

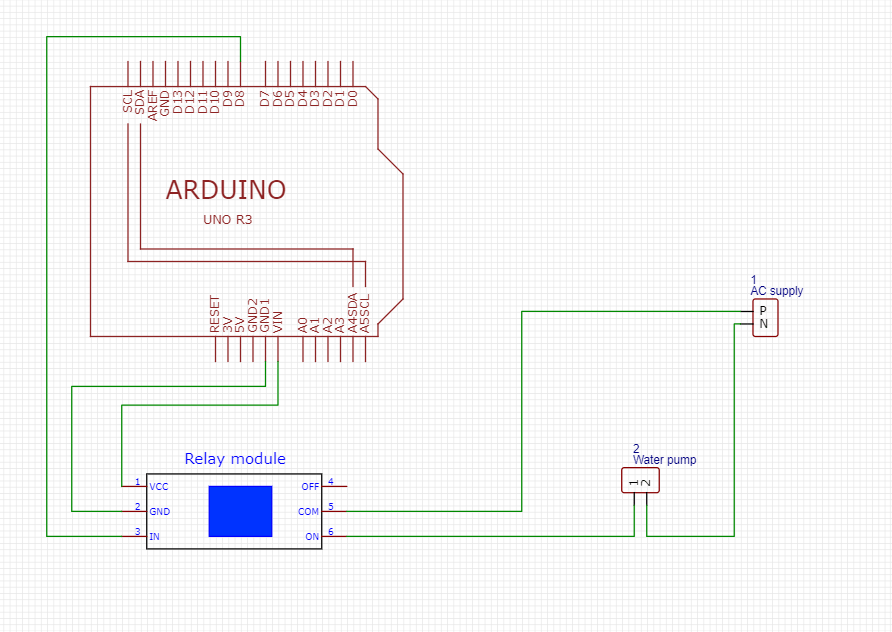

- Arduino UNO board

- Relay

- Adapter(9V, 2A)

- Jumper Wires

- 5mm wire

- Netpots

- WORKING :

- The existing DWC system can hold 7 litres of water. That means if we add 7 litres of our dosing solution, the net pot will fully be dipped in the solution.

- I used a submersible water pump of 19W which can pump water upto a height of 1.85m and then calculated the amount of time it took to fill the container.

- It took 55 seconds to completely fill the container.

- To convert the DWC system to Flood and Drain system Siphon Mechanism is used.

- Once the container is filled i.e after 55 sec the arduino commands the relay to turn the pump off and the pump stops pumping the water.

- The moment pump stops pumping the water due to gravity water is pulled in downward direction into the bucket that is placed below

- In this way a simple siphon mechanism can be used for flood and drain system.

WHAT IS SIPHON MECHANISM ?

Siphon is a tube that allows liquid to travel upward, above the surface of the origin reservoir and then downwards to a lower level without using a pump. When a certain amount of water moves over the bend in the siphon after that on the longer leg of the siphon, gravity pulls it down. Ancient Egyptians used Siphon in wine making process and in todays era it has wide range of application.

**IMPORTANT CONSIDERATION FOR SIPHON MECHANISM: The water level of the container from which we have to drain water must always be at higher elevation than the container in which we have to collect it.

- ELECTRIC CIRCUIT :

- ARDUINO CODE FOR WATER PUMP :

#define ralaypin 8

unsigned long value = 0;

long value1 = 0;

void setup() {

pinMode(relaypin, OUTPUT);

Serial.begin(9600);

}

void loop() {

digitalWrite(relaypin,LOW);

//Serial.println(“MOTOR ON”);

for(value1 = 0; value1<=55; value1++)

{

Serial.print(value1);

Serial.println(” MOTOR ON”);

delay(1000);}

digitalWrite(relaypin, HIGH);

value1 = 0;

for(value = 0; value<=1200; value++)

{

Serial.print(value);

Serial.println(" MOTOROFF");

delay(1000);}

value = 0;

}

(20/10/2021 to 21/10/2021)

SELECTION OF GROWING MEDIA :

- GROWING MEDIA SELECTED;

- cocopeat : vermiculite : sand – 3 : 1 : 1

PLANTATION OF CHRYSANTHEMUM IN NET POT :

chrysanthemum plant

Filing growing media in the net pots

planting cut chrysanthemum in the net pot

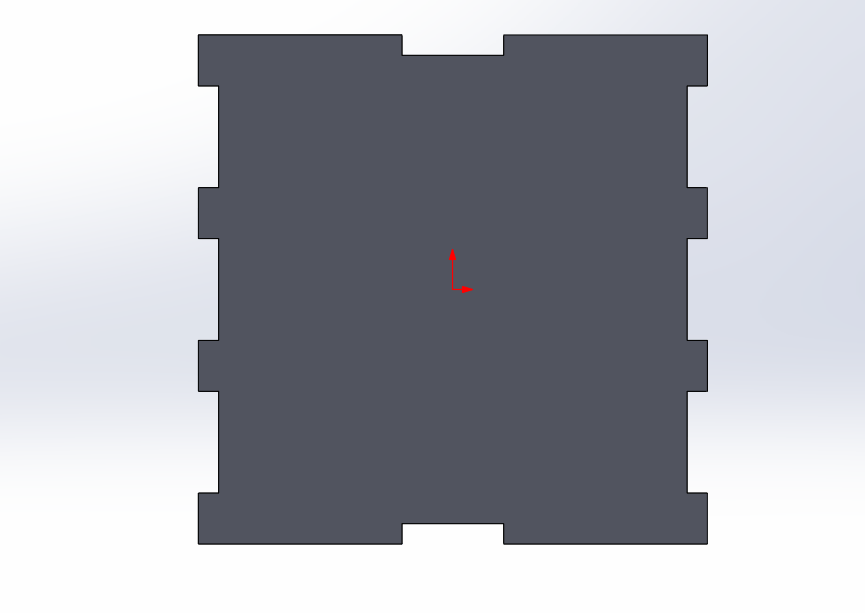

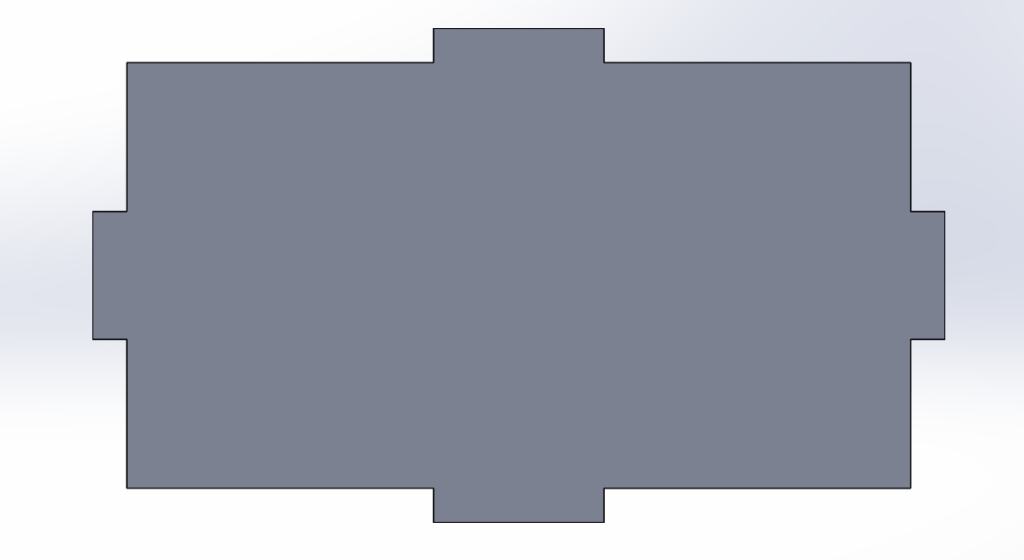

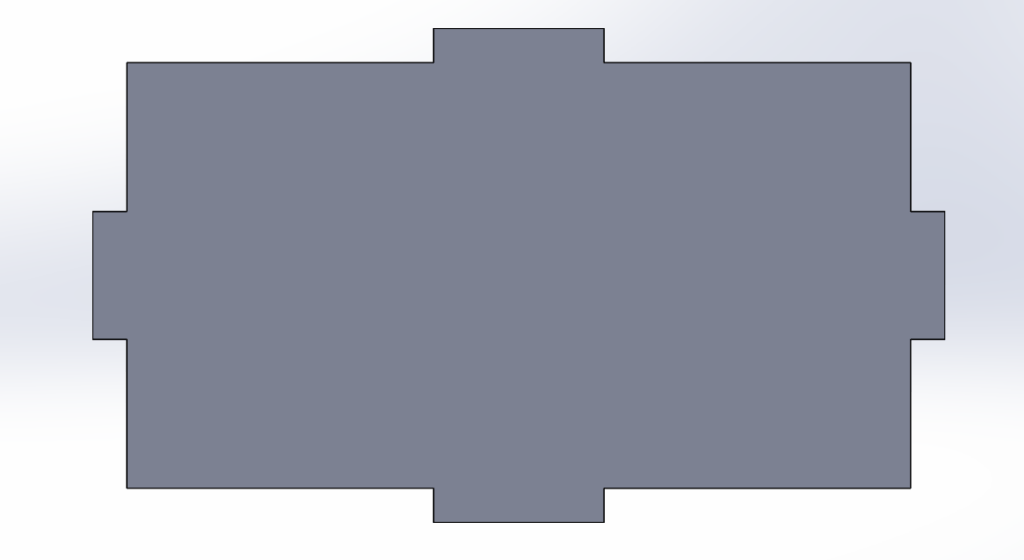

- SOLID WORKS DESIGN FOR ENCLOSURE OF ARDUINO AND RELAY :

Solidworks CAD DESIGNS :

- Operation :

- Dimentions of circuit connections.

- 2D sketching.

- Extrude the surface into solid modelling.

- Press-Fit assembly. ( mate operation )

BASE PLATE

TOP PLATE

RIGHT SIDE PLATE

LEFT SIDE PLATE

SIDE PLATE

SIDE PLATE

ASSEMBLY

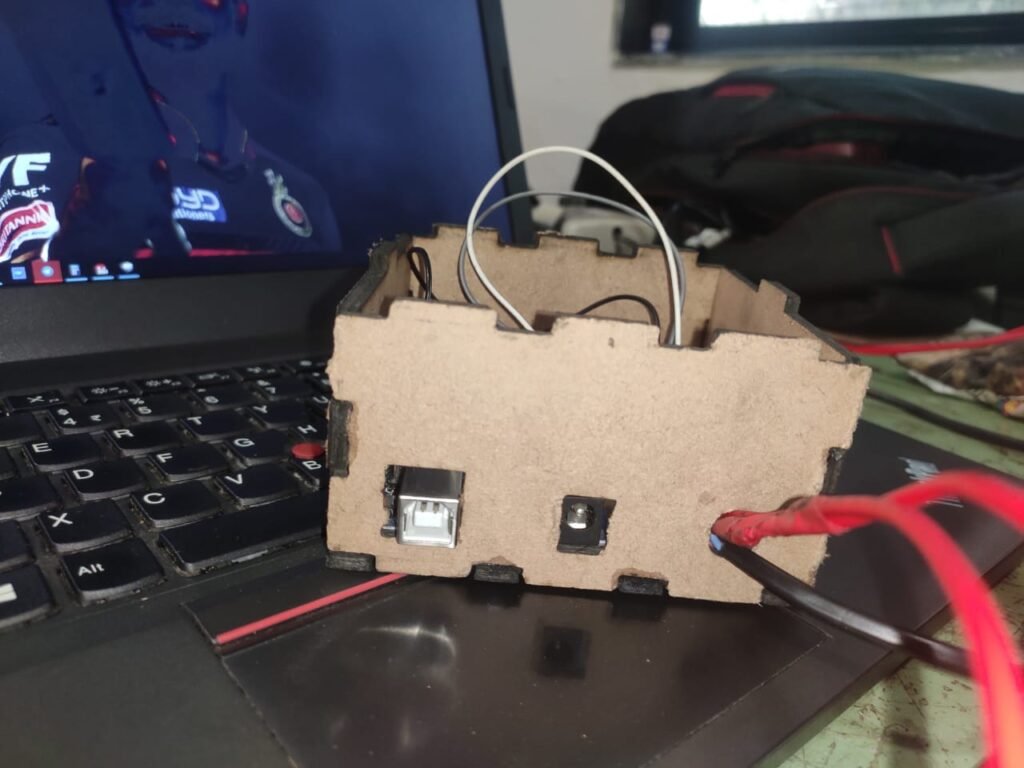

- LASER CUTTING OF ENCLOSURE :

To cut the above CAD model parts we convert .sldprt file into .dxf file. In that we use MDF material for enclosure and cut it using CNC laser cutting.

- Operations :

- Convert solidworks CAD File ( .sldprt ) into .dxf file using solidworks.

- Laser cutting software RD-WORKS – conversion of .dxf file into code file.

- Setup speed and other parameters for MDF material for laser cutting.

- Remove the part and assemble properly using press fit and glue.

laser cutting operation

laser cutting operation

circuit connections and enclosure assembly

side ports opening

- WORKING VIDEO :

RESULTS OBSERVED :

20/11/2021

26/11/2021

28/11/2021

30/11/2021

2/12/2021

6/12/2021

- Vegetative growth of chrysanthemum was observed to be very fast.

- Didn’t collect the data for flowering growth due to my internship timeline issues.