Project Background

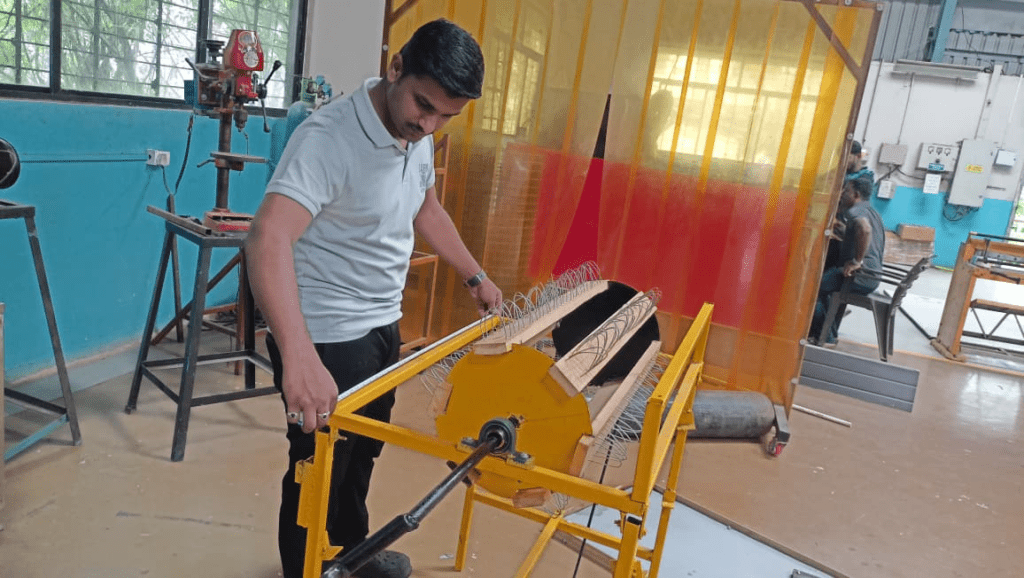

This project was assigned by the IBT (Introduction to Basic Technology) Department of Shri Bhairavanath Madhyamik Vidyalay, Vahangaon. The rice thresher machine was originally developed by the IBT school students. Now, the department aims to commercialize this machine by improving its performance, usability, and cost-effectiveness.

Understanding the Requirements

Before starting the modification, I interacted with the IBT team to understand their expectations and practical requirements. The key points identified were:

- The machine should be easily movable for farmers to carry it from one place to another.

- It should have low maintenance and be repairable using locally available materials.

- If the budget allows, the machine should run on a motor or solar power, apart from manual operation.

- The final model must remain affordable and user-friendly for small and marginal farmers.

Market Survey and Analysis (27/09/2025)

After understanding their needs, I conducted a short market survey to study existing rice thresher machines, their design structure, materials used, and price range.

This survey helped to identify:

- The strengths and limitations of available machines.

- Possible design improvements for better mobility and efficiency.

- The estimated market price range for small-scale threshers.

Machine Study and Cost Calculation (Started on 28/09/2025)

From 28/09/2025, I started taking the complete dimensions of the existing thresher machine developed by the students. Each part of the machine was measured carefully for redesigning and cost recalculation.

After that, I prepared a detailed Excel sheet including:

- Material names

- Quantities

- Unit costs

- Total costing

This sheet helped to calculate the current manufacturing cost of the existing thresher.

🧾 Discussion and Quotation Preparation

After completing the measurements and cost analysis, I discussed the findings with Prasad Sir and Abhijit Sir. Based on their feedback, we prepared a quotation for the modified version of the rice thresher machine and shared it with the IBT department for review and approval.

26/10/2025

So after getting quatation aproval we start work again and now firstly we have to calculate the RPM of innitial drum and along with that what hp motor required for new machine . so for that I take some reading and do some calculations are as follow

Step 1: Given Readings

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Pedal presses for 1 roller rotation | N₁ | 1.5 to 2 | presses |

| Pedal presses in 10 seconds | N₂ | 9 to 10 | presses |

| Pedal travel distance | Dₚ | 10 | cm |

| Roller diameter | Dᵣ | 30–32 | cm |

Step 2: Calculate Roller Rotations per 10 seconds

If 1.5 pedal presses = 1 rotation,

then in 10 seconds (9 presses): Roller Rotations in 10 sec=91.5=6 rotations\text{Roller Rotations in 10 sec} = \frac{9}{1.5} = 6 \text{ rotations}Roller Rotations in 10 sec=1.59=6 rotations

If 2 pedal presses = 1 rotation,

then in 10 seconds (10 presses): Roller Rotations in 10 sec=102=5 rotations\text{Roller Rotations in 10 sec} = \frac{10}{2} = 5 \text{ rotations}Roller Rotations in 10 sec=210=5 rotations

So we can take an average of 5.5 rotations per 10 seconds.

Step 3: Convert to RPM (Rotations per Minute)

RPM=5.5 rotations10 sec×60=33 RPM\text{RPM} = \frac{5.5 \text{ rotations}}{10 \text{ sec}} \times 60 = 33 \text{ RPM}RPM=10 sec5.5 rotations×60=33 RPM

✅ Estimated manual roller speed ≈ 30–35 RPM

Step 4: Required Motor RPM (Modified Machine)

If you plan to replace pedal action with an electric motor, then the motor should achieve approximately the same roller speed (≈ 33 RPM).

However, most motors run at much higher speeds (e.g., 1440 RPM or 960 RPM), so you’ll need a pulley or gear reduction system.

⚙️ Step 5: Pulley Ratio Calculation Example

Let’s assume you use a 1440 RPM motor and want 33 RPM at the roller. Speed Ratio=144033≈43.6\text{Speed Ratio} = \frac{1440}{33} \approx 43.6Speed Ratio=331440≈43.6

So the pulley diameter ratio should be around 1:43.

For example:

- Motor pulley = 3 cm

- Roller pulley = 3 × 43 ≈ 129 cm

That’s quite large, so instead, you can use two-stage reduction (e.g., 1:7 × 1:6 = 42) using intermediate shafts.

⚙️ Step 6: Motor Power Estimation (Approximate)

If manual pedaling speed = 30 RPM and you want a similar torque, then typically a 0.25–0.5 HP motor (≈180–370 W) would be sufficient for small threshers.

✅ Final Result Summary

| Parameter | Result | Remark |

|---|---|---|

| Manual roller RPM | 30–35 RPM | Average human speed |

| Required roller RPM (motorized) | 30–35 RPM | To maintain same threshing performance |

| Suitable motor | 0.25–0.5 HP | 1440 RPM standard motor |

| Pulley ratio | ≈ 1:43 | Use two-stage belt reduction |

| Roller diameter | 30–32 cm | With attached plates |

Basic Data and Assumptions

From our existing manual thresher, we collected the following data:

| Parameter | Symbol | Value |

|---|---|---|

| Weight of roller (modified) | W₁ | 8 kg |

| Weight of paddy bundle | W₂ | 3 kg |

| Total load on roller | W | 11 kg |

| Required speed of roller | N | 150 RPM |

| Type of drive | — | Belt Drive |

| Roller diameter | D | 30 cm (0.3 m) |

| Two motor positions | D₁ = 1 ft (0.304 m) D₂ = 2.78 ft (0.847 m) | D1= Motor is placed near to the drum D2 = Motor is placed at downward side of machine and motor and drum distance is high . |

4. Torque Calculation

https://drive.google.com/file/d/1q44VmHwGwYlSnEyNAe_z9w27D57c_kz7/view?usp=drivesdk

6. Motor Selection Discussion

From survey and testing:

- Manual pedal operation generated about 100–150 RPM.

- Market-available threshers use motors of 0.5 HP to 1 HP for small-capacity threshers.

- Using gear reduction (typically 1:10 to 1:15), the torque can be increased while maintaining manageable speed.

Hence, a 0.5 to 1 HP single-phase motor with a suitable gear reduction unit is enough to achieve 300–400 RPM roller speed efficiently.

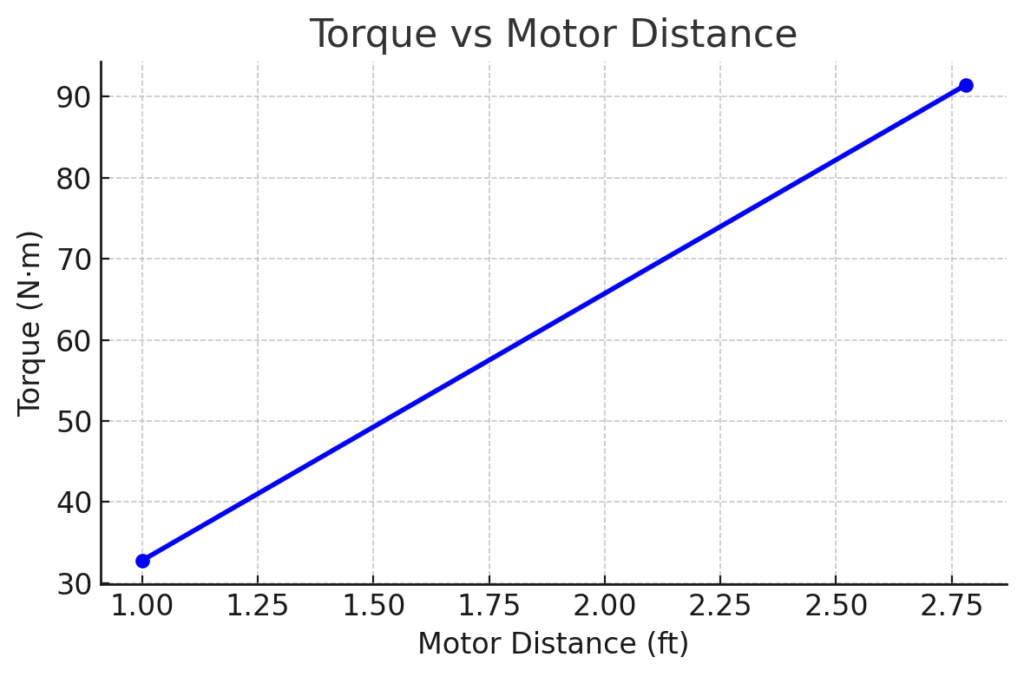

🔁 7. Effect of Motor Position

The distance between motor and roller affects torque:

- When the motor is near the roller, torque requirement is low (32.8 N·m).

- When the motor is placed downward, torque increases to 91.4 N·m because of longer belt length and more frictional loss.

➡️ Therefore, placing motor close to the roller is more energy-efficient and compact in design.

🛠️ 8. Proposed Improvements

- Design compact frame using CAD modeling (SolidWorks / Fusion 360).

- Use belt drive with proper tension adjustment.

- Include safety cover and vibration damping pads.

- Use ball bearings to reduce friction.

- Attach interchangeable sieve for different crop types.

Graphical Representation

(A) Graph 1: Torque vs Motor Distance

| Motor Distance (ft) | Torque (N·m) |

|---|---|

| 1.0 | 32.8 |

| 2.78 | 91.4 |

→ A simple line graph showing torque increasing with distance.

Torque vs Motor Distance — This shows that when the motor is placed farther (larger distance from the roller), torque requirement increases sharply.

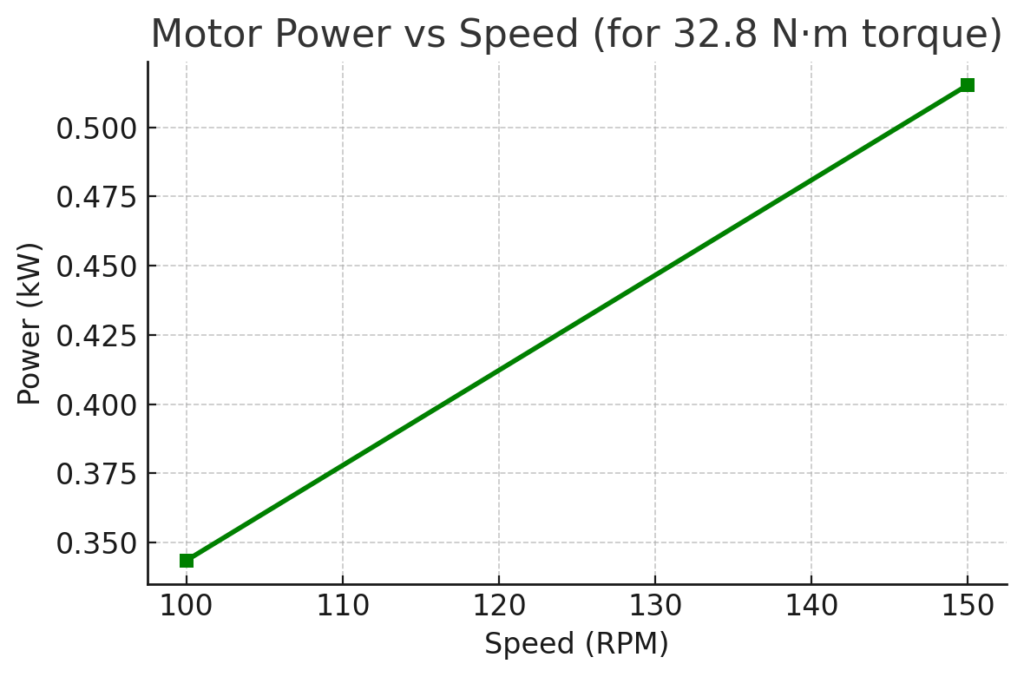

Motor Power vs Speed — This shows that motor power rises with increasing speed (RPM) for a constant torque.

(B) Graph 2: Motor Power vs Speed

For each case (100, 150 RPM), show how required HP rises with speed.

Motor Power vs Speed — This shows that motor power rises with increasing speed (RPM) for a constant torque.

Market Analysis

Here’s a summary of each with highlights:

- Micro Mill Paddy Thresher Machine (0.5 HP): 0.5 HP motor type, small-scale. Good match for your target motor size.

- Link: Yantratools product (₹19,500 for 3-feet body) yantratools.com

- Specs: 450 mm dia × 760 mm length cylinder, ~55-60 kg weight.

- Use in blog: shows what 0.5 HP electric models offer in market.

- Paddy Thresher with Engine (0.5‑5 HP): broader HP range (0.5 to 5 HP) engine driven.

- Link: TradeIndia listing TradeIndia

- Capacity: 1000-1500 kg/hr for higher HP.

- Use: Good to show market upper range and how HP relates to capacity.

- Manual Paddy Rice Thresher Machine: fully manual model, no motor.

- Link: Yantratools manual variant yantratools.com

- Weight ~40 kg; useful for your manual pedal part of design.

- Manual 2.5 Feet Paddy/Rice Thresher Machine: budget small size manual machine.

- Link: [Toolsvilla listing] with price ~₹9,999 for 2.5 ft body. yantratools.com+1

- Use: shows how small scale manual machines are in market.

- Paddy Rice Thresher with 7 HP Petrol Engine: higher power engine driven model (7 HP) good for capacity beyond your target.

- Link: ManoharYug listing ManoharYug

- Use: contrasts your small-scale design.

- Balwaan Corn/Thresher CT‑500 With Motor: Although for corn, still relevant motorised thresher.

- Link: Amazon listing ₹13,500 for motorised thresher.

- Use: shows motorised thresher price lower range.

- AV‑8A 3 Feet Paddy Thresher with 0.5 HP Motor: 0.5 HP motor single phase, market spec drum speed 300-400 RPM.

- Link: Toolsvilla listing toolsvilla.com

- Use: directly comparable to your target design.

- 2 in 1 Paddle Cum Power Paddy Thresher with 0.5 HP Motor: Hybrid manual+motor model (2-in-1).

- Link: Yantratools 2 in 1 model yantratools.com

- Use: Very useful because it matches your hybrid concept (manual + motor).

10. Conclusion from calculations

From the calculations and analysis, we conclude that:

- The motor position significantly affects torque and power requirements.

- For small-scale threshing (11 kg total load), 0.5 to 1 HP motor is sufficient if the motor is placed close to the roller and operated via a belt reduction system.

- Manual operation achieves around 100–150 RPM, while motorized systems can easily reach 300–400 RPM, improving efficiency and reducing fatigue.

This study provides a foundation for designing and fabricating a low-cost rice thresher suitable for small farmers and rural use.