2nd September

Today I received my project on Onion Preservation. This raised several key questions in my mind: Which types of onions can be preserved effectively? Why do onions degrade during storage? To guide my work, Prasad Sir instructed me to gather information directly from farmers who own onion farms and to understand their concerns regarding onion storage.

3rd September

I contacted Lakshman Jadhav Sir to obtain farmer contact details in Pabal and nearby villages. Through him, I collected around 12–15 contacts, which will be valuable for farmer consultations. Visited the nearby village chals.

5th September

Using the phone numbers, I connected with farmers to learn about their storage practices. Simultaneously, I began reviewing literature on onion storage. From my discussions, I identified three common types of onion damage:

- Sprouting

- Fungi (rotting)

- Physical weight loss

As advised by Prasad Sir, I visited the Agrorangrs office for additional data and insights. There, I met Vivek, who provided me with an overview of onion farming and common storage issues.

6th September

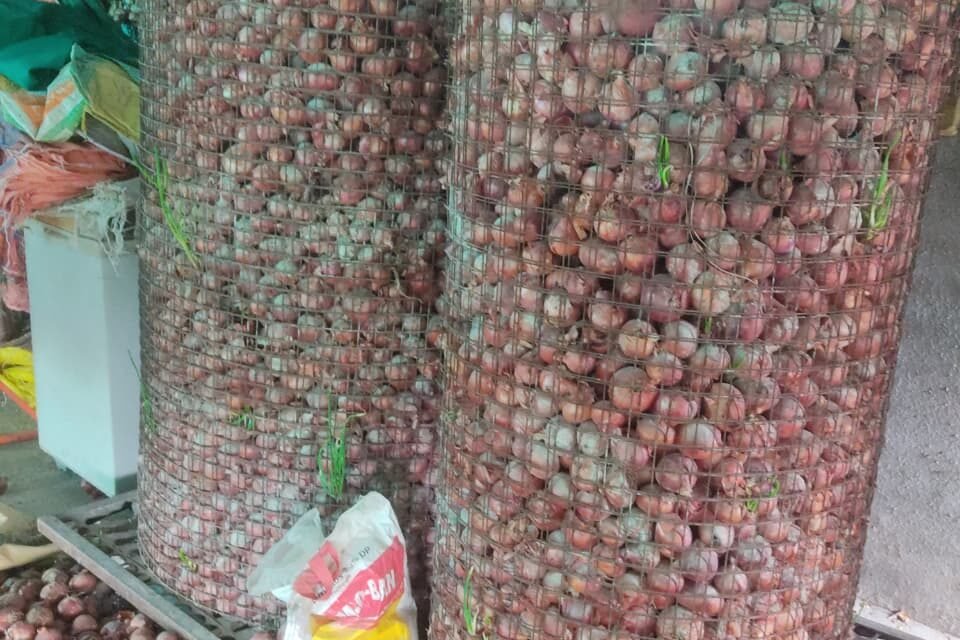

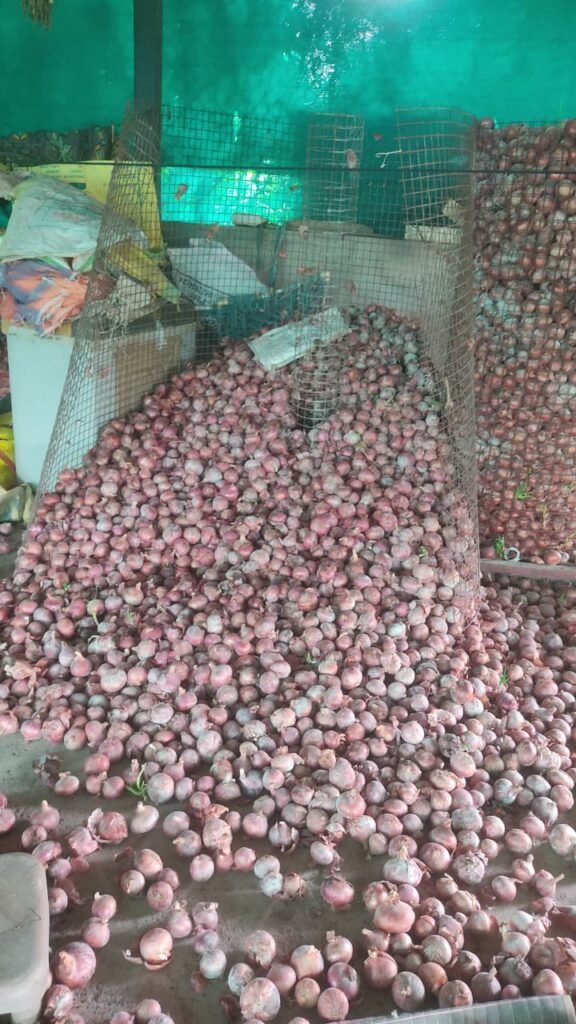

With the help of Ganesh Pinggale Sir, I got in touch with an administrative officer at the ICAR – Directorate of Onion and Garlic Research. I scheduled a meeting for the 8th of September. Visited one of the farmers who stored onions in a circular iron net structure.

7th September

I reviewed all the data collected so far and prepared a PowerPoint presentation to summarize the problems associated with post-harvest losses and onion storage. During the review, Prasad Sir emphasized the importance of studying the gases released by onions at different stages, as this could help detect the degradation period more accurately.

8th September

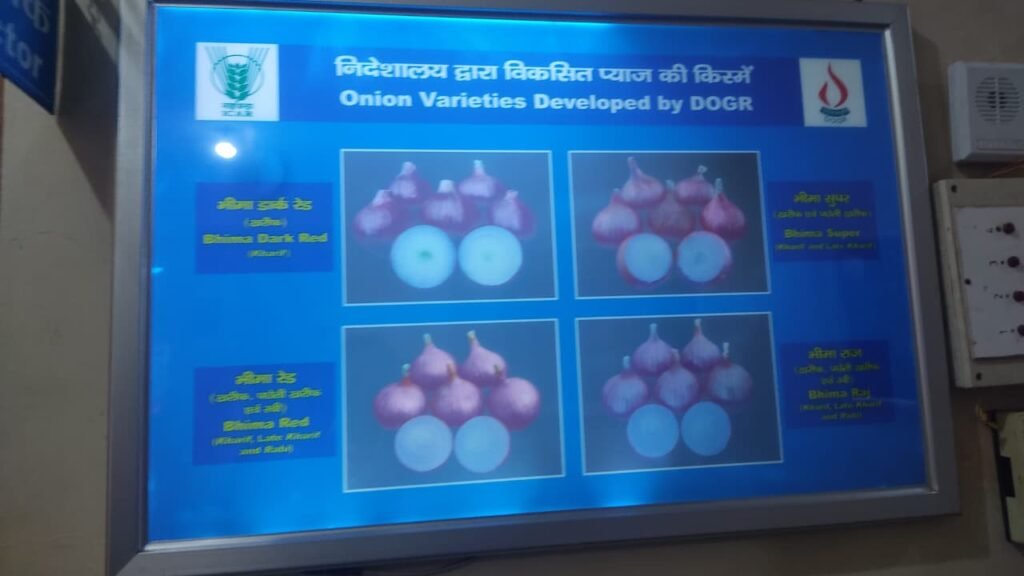

I connected to Hemant Gawali sir through Ganesh Pingale sir on a call, and I booked an appointment for a discussion on onion storage for the 8th of September 2025 in the afternoon. While I was talking about the science behind the onion degradation, Hemant Sir sent me to Bhushan Sir, a senior scientist in the ICAR department of onion storage. Had a meeting with Bhushan Sir for long enough to address the problem of onion storage.

The ICAR – Onion and Garlic Research Center, where I met with Dr. Bhushan Sir to discuss post-harvest problems and potential solutions. I also obtained a manual on onion storage, which will be very useful for the project.

ICAR Visit report- https://docs.google.com/document/d/1ggaMFDvFFzxXGa1y-tldCqUM-uZ8-2OqTWts0jPEjkw/edit?usp=sharing

9th September

To collect further farmer data, I visited the Sarpanch of Pabal village and later consulted with the Krishi Sevak. These interactions provided more on-ground insights into local storage challenges.

11th September

I studied the sprouting process in onions and focused on the acids responsible for its initiation. I found that Abscisic acid (ABA), produced by onions, initially inhibits sprouting. However, over time, the ABA level decreases, which allows the production of Gibberellin acid (GA) along with small amounts of ethylene. This biochemical shift triggers the onset of sprouting.

12th September

I visited the nearby village to take measurements of a small iron-net storage unit used by farmer Pandhurang Gavle. The structure dimensions were 2 ft in diameter and 5 ft in height. These details will be important for evaluating storage design and capacity. In the afternoon, I continued my literature review on onion sprouting, specifically focusing on techniques to reduce the sprouting rate.

13th September

Prasad Sir assigned me the task of calculating the capacity of the storage unit I measured yesterday. Using the given dimensions, I applied the volume formula for a cylinder and multiplied by the bulk density of onions.

- Height (h): 5 ft = 1.524 m

- Diameter (d): 2 ft → Radius (r) = 1 ft = 0.305 m

- Volume (V): π × r² × h = 3.1416 × (0.305)² × 1.524 ≈ 0.446 m³

- Bulk density of onion (ρ): 400 – 600 kg/m³

- Mass capacity (M) min : ρ × V = 400 × 0.446 ≈ 178 kg

- Mass capacity (M) max: ρ × V = 600 × 0.446 ≈ 267 kg

Thus, the storage unit can hold approximately 178 to 267 kg of onions.

Alongside this calculation, I also studied whether abscisic acid can be applied externally to onions, and searched for any research conducted on this approach. In the afternoon, I guided a group of five students from Nashik on a tour of Vigyan Ashram.

14th September

We had the weekly review of the project, during which I presented my findings on the effect of temperature and humidity parameters on onion storage. Prasad Sir assigned me the task of finding possible dimensions for a circular iron-net structure capable of storing 1000 kg of onions.

Using the bulk density of onions (≈ 570 kg/m³) and the formula for volume:

- Required volume (V): Mass ÷ Density = 1000 ÷ 570 ≈ 1.754 m³

I explored three combinations of height (h) and diameter (d) for the cylindrical storage unit:

- h = 1.5 m, d ≈ 1.22 m

- h = 2.0 m, d ≈ 1.06 m

- h = 2.5 m, d ≈ 0.95 m

These dimensions provide flexible design options depending on available space and structural feasibility.

15th September

During a conversation with visiting Nashik students, Prasad Sir explained that onions require oxygen for aerobic respiration, and if oxygen is not supplied sufficiently, they rot faster due to anaerobic reactions. This inspired me to read research papers on aerobic vs. anaerobic respiration in onions, as well as literature on the effects of light, temperature, moisture, oxygen, and CO₂ demand in storage.

I also completed my Google form submission for the project.

16th September

I continued studying the impact of light on onion storage. I focused on identifying how different proportions of light exposure can affect storage outcomes. Additionally, I prepared an Excel sheet to organize the data of farmers I had consulted regarding onion farming and storage.

Farmers details-

https://docs.google.com/spreadsheets/d/11MudxR4Rbc1Jtj2I1qp9Tsdh1o6sc7EYQCTqEdTBqI8/edit?usp=sharing

17th September

I visited Dnyaneshwar Kashid to coordinate arrangements for the upcoming two-day visit of IITB students. Later, during a discussion with Dixit Sir, I presented a table I had prepared that consolidated key storage parameters: temperature, moisture, light, air velocity, oxygen, and CO₂. He advised me to further research two new aspects:

- The pressure exerted by onions on themselves inside a storage unit.

- Possible chemical or natural treatments (ozone, formaldehyde, neem extract, garlic extract) that can be applied before storage to minimize losses.

| Parameter | Effect on Sprouting | Effect on Rotting | Effect on Weight Loss | Recommended Optimal Range/Condition | Key References |

| Light (Dark vs White/UV/Blue) | Darkness accelerates sprouting; White/UV/Blue light delays sprouting | Indirect: light boosts antioxidants, reduces microbial decay | Dark = faster metabolic activity; Light may reduce loss via antioxidants | Keep in diffused light / low-intensity white or blue light if possible; avoid prolonged dark storage | Sharma & Gupta, 2016; Brewster, 2008 |

| Temperature | High temp (>20°C) accelerates sprouting; Low temp (0–4°C) delays sprouting | High temp accelerates microbial activity; Low temp slows it | High temp = high respiration & moisture loss; Low temp reduces loss | 0–4°C for long-term cold storage or 25–30°C for short-term (≤3 months) well-ventilated storage | Lee et al., 2017, Tripathi & Lawande, 2006 |

| Relative Humidity (RH) | Indirect: high RH promotes rooting/sprouting | High RH (>80%) encourages fungal rots | Low RH (<55%) causes shriveling and weight loss | 65–75% RH (prevents fungal growth while limiting excessive weight loss) | Kaya & Singh, 2018, Joshi & Narkhede, 1990 |

| Oxygen / CO₂ Balance | Low O₂ slows sprouting; very low O₂ may cause fermentation | High CO₂ can suppress some fungi; anaerobic conditions cause spoilage | Not major; indirectly affects respiration | Normal air storage with good ventilation or Modified Atmosphere: 2–5% O₂, 2–5% CO₂ for controlled storage | Yamaguchi & Pratt, 1964, Rylski et al., 1974 |

| Curing (Pre-storage) | Proper curing reduces sprouting risk | Curing hardens scales, closes necks, reducing microbial entry | Well-cured bulbs lose less moisture | 14–21 days curing at 30–40°C, RH 60–70% with good airflow until outer scales are dry and necks tight | Tripathi & Lawande, 2002, Selvaraj & Pal, 1987 |

| Ethylene (Gas Treatment) | Exogenous ethylene (in closed systems) suppresses sprouting | No direct effect on rotting | No direct effect | Optional: 100–150 ppm ethylene fumigation in closed systems, monitored carefully | Bufler, 1981, Pak et al., 1995 |

| Ventilation | Good airflow reduces localized heat that can trigger sprouting | Prevents moisture buildup that favors rotting | Maintains balanced moisture, reduces shrinkage | Continuous or periodic airflow, 20–40 air changes/hour to prevent hotspots and moisture accumulation | Tripathi & Lawande, 2005, FAO, 2003 |

| Bulb Maturity & Handling | Immature/damaged bulbs sprout faster | Damaged bulbs rot faster | Immature bulbs lose weight faster | Store only fully mature, dry-necked, undamaged bulbs; handle gently to prevent bruising or skin breakage | Brewster & Salter, 1980, Pandey & Varma, 1975 |

19th September

I visited the polyhouses of Chetan Ghare and Dnyaneshwar Kashid to confirm farmer availability for visits planned on the 22nd and 23rd of September. Meanwhile, I also began reading about the application of ozone treatment in onion storage, focusing on its effectiveness in reducing post-harvest losses.

11th October

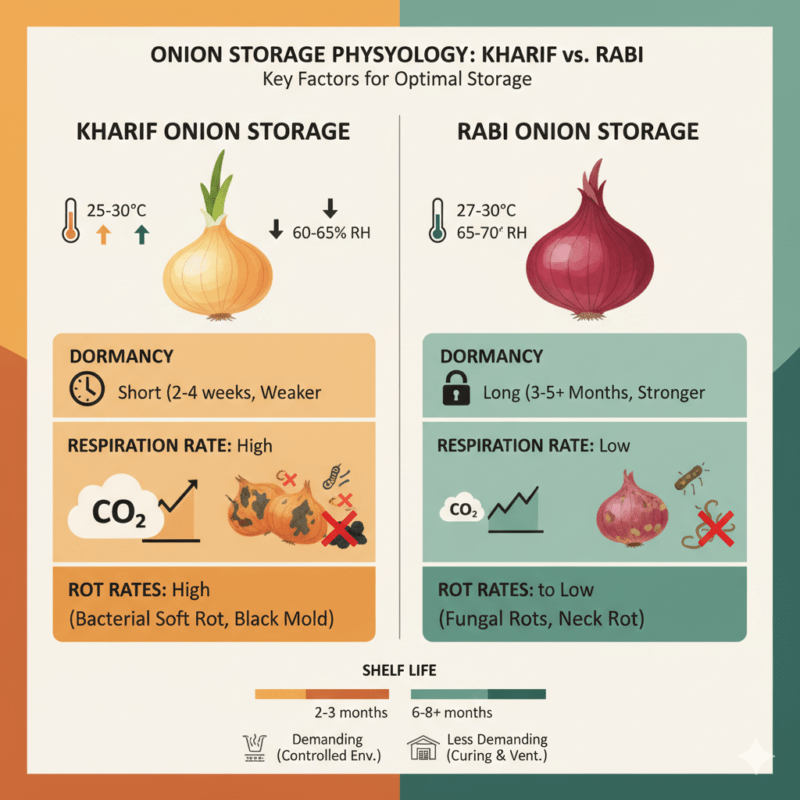

After consulting with Dixit Sir, he advised me to explore the chemical mechanisms of three processes:

- Ozone treatment

- Formaldehyde treatment

- Kharif onion storage limitations and improvements

From my initial study on Kharif onions, I derived the following key findings:

- High moisture content → leads to incomplete curing

- Warm, humid air → increases respiration rate

- Short dormancy period → causes early sprouting

- Thin outer scales → result in higher microbial infection risk

12th October

Today I had a Discussion on the parameters that i found through research in all days with Dixir sir and Abhijitt sir.

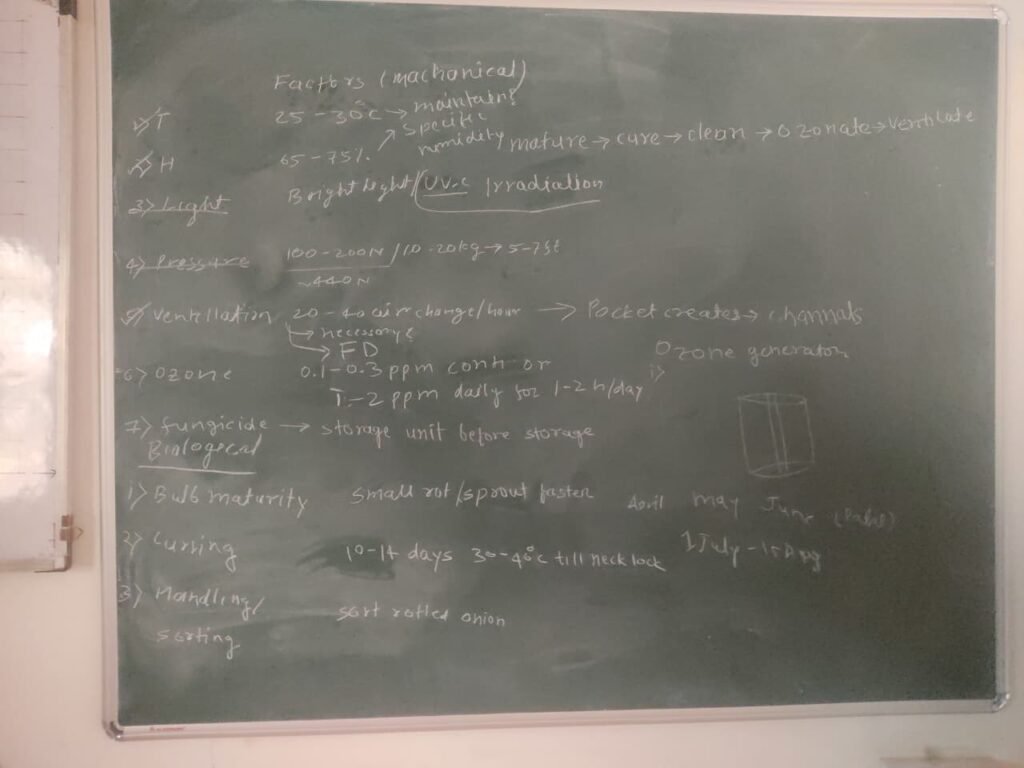

I explained all parameters that I concluded will affect the onion storage unit, including temperature, humidity, light, pressure, ventilation and ozone treatment.

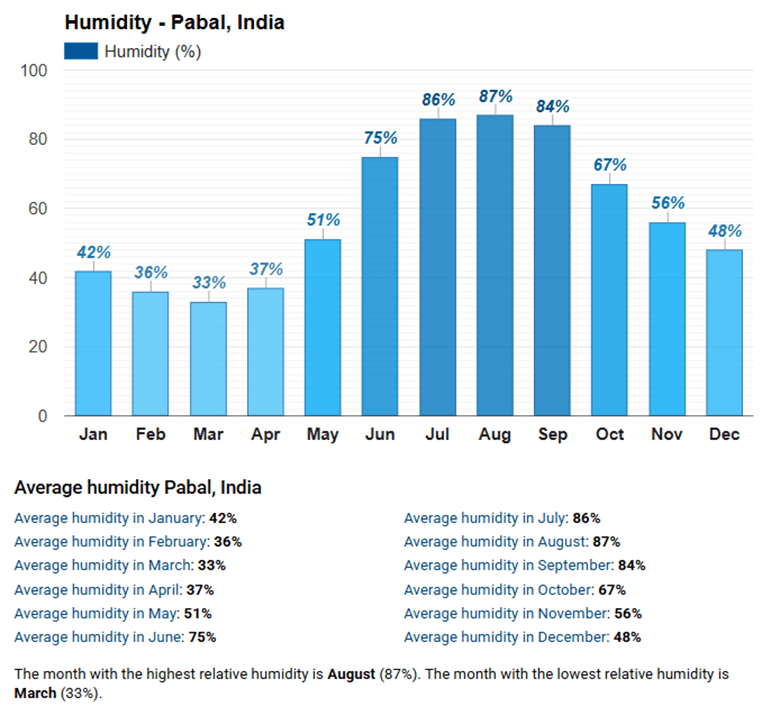

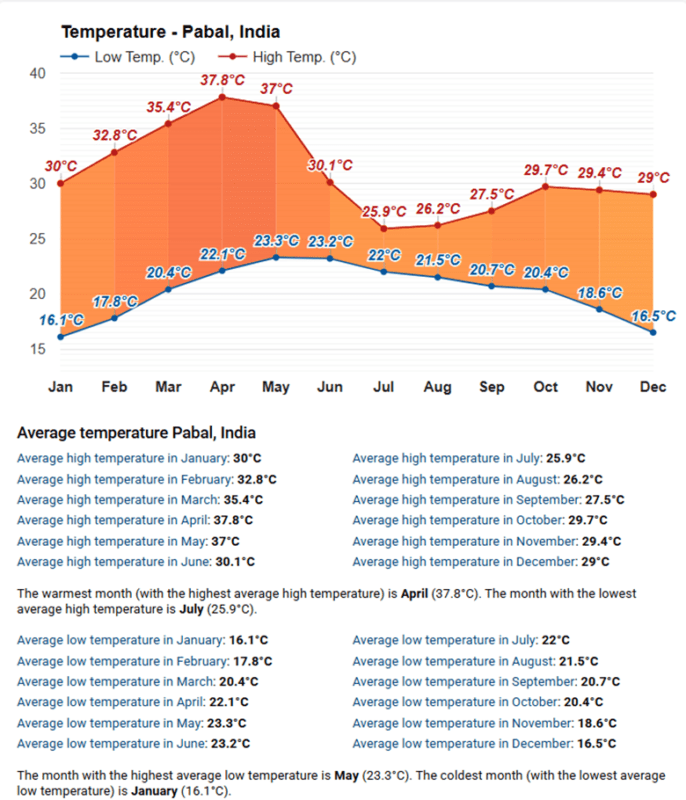

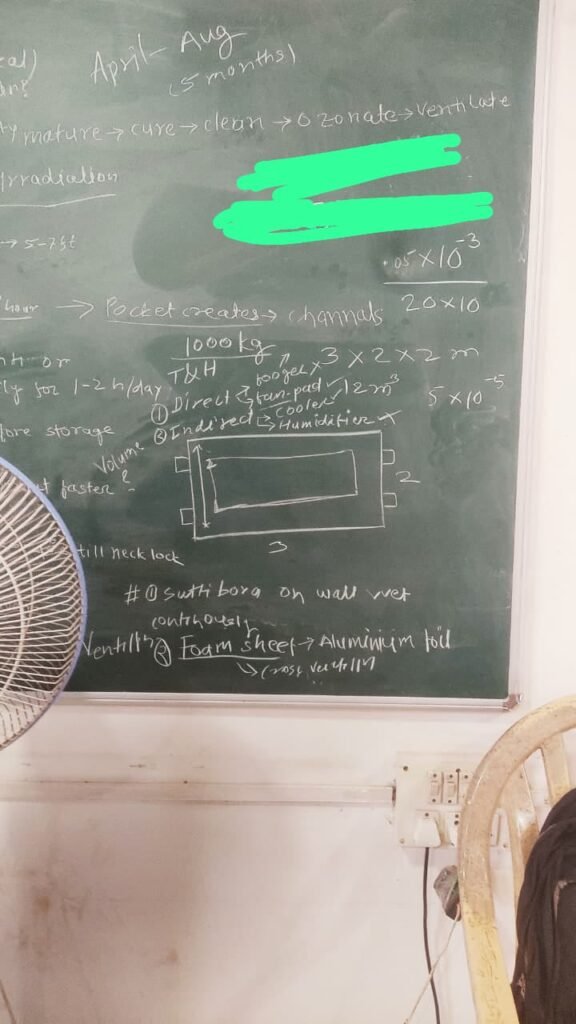

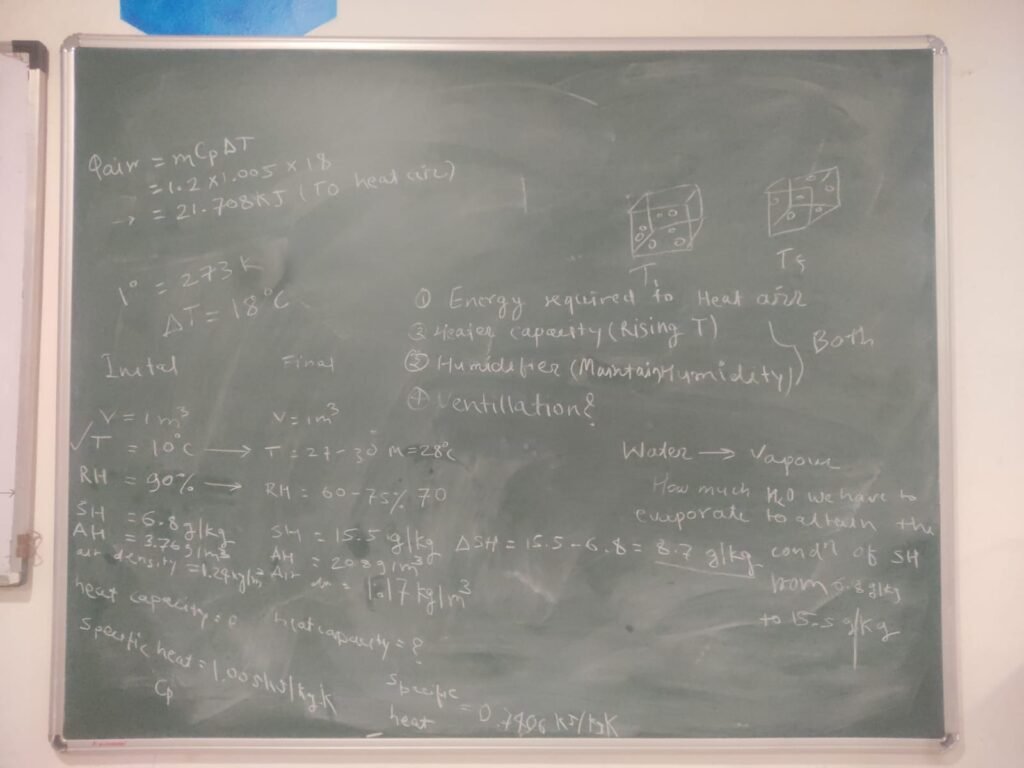

Out of these, I will go to study about the temperature and humidity first because if the outside temperature is 40 degrees, then how can I reduce it to 30, and the same goes for the humidity. If outside humidity is 20-40% how can I manage to 65-75%? I will have to study the cycle of the month during onion storage, like April to August, to calibrate the environment around the onion storage unit.

Second point, sir pointed out is ventilation. If we are sucking or giving air inside, there will be some pockets inside the room, or the channel will create how I can remove or reduce them?

The pressure exerted by the onion is much lower, i.e., 100-200N from 5-7foot then it will not be much issue; some goes to the Ozone. We will be going to work after the temperature and humidity are controlled with proper ventilation.

when had a discussion with dixit sir sir told me about the challenges of ventilation of air if “if you want to remove air from onion still there would be some part of onion will not pass the air and will create the air pockets or channels how will you tackle this problem” second point he advises me for the temoreture of the paball is around the 40degree celcious outside then how will you going to manage gthe inso=ide tempreture at 25-30 that is right third the Humidity outside it relatively low then how will you going to attend thye humidity at thr 65% he aadvesis me to study about the Specific humidity inside the room

However, the discussion focuses on most aspects of the climatic conditions of the Pabal region, in accordance with the onion storage cycle, which starts from April to August. These months have different weather patterns; how can I manage the temperature and humidity? During the meeting, I missed the point about the volume and size of the room required for 1000kg of onions.

Starting with the humidity, I look at the various steps to reduce the temperature inside the room from two ways: direct humidification and indirect humidification. For humidification, I must know the specific volume of the air inside the room and the outside temperature. The initial phase if the research prasad sir told me about the specif requirementys of 1000kg so for that when I calculate the dimeter it is –

The compact room volume of 12 m³ ( 3.0 × 2.0 × 2.0 m). Length * height *width

So the total volume I got is 12m3 for the removal of gthis volume we must the ventilation are as follows-

- Room volume

= 12 m³.

- Required air changes: 20–40 ACH.

- Airflow needed:

- 20 ACH → Q = 240 m³/h ≈ 4.00 m³/min ≈ 141 CFM

- 30 ACH → Q = 360 m³/h ≈ 6.00 m³/min ≈ 212 CFM

- 40 ACH → Q = 480 m³/h ≈ 8.00 m³/min ≈ 283 CFM

Pick a fan system rated for ≈ 200–300 CFM if you want 30–40 ACH. Use multiple smaller fans rather than one very large fan to improve distribution.

Now I have the represented data for the air circulation

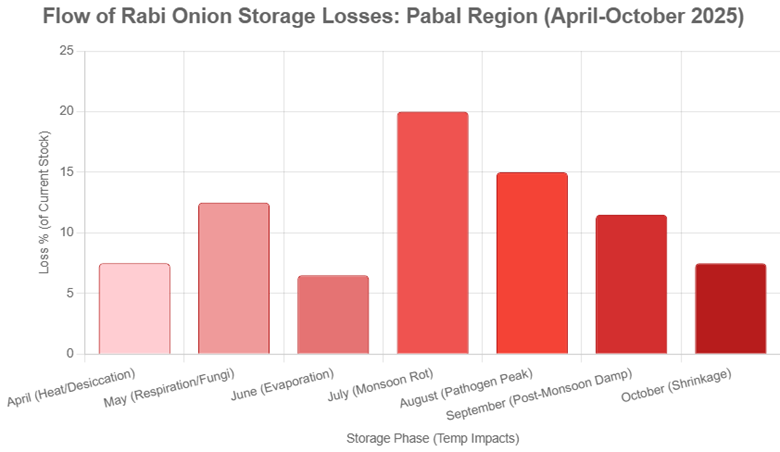

The cycle of the Rabi onion starts with the April

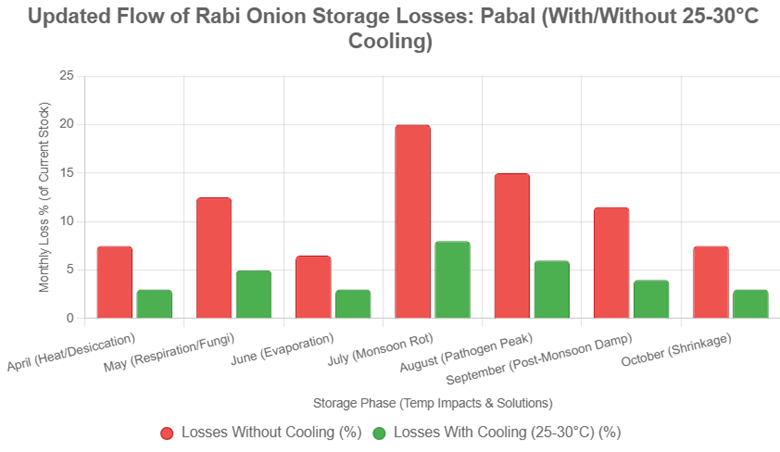

- April (Harvest/Curing: High 37°C, Low 23.1°C): Peak heat stresses curing (field/windrow drying); internals hit 35-38°C, accelerating moisture loss (5-8% in 7-10 days). Risk: Sunscald on necks, early desiccation. Losses: 5-10% if not shaded.

- May (Curing End/Storage Start: High 37.8°C, Low 23.3°C): Hottest month; respiration surges, promoting fungal entry (e.g., black mold). Cylindrical vents help cool 2-3°C via breeze, but >35°C triggers 10-15% weight loss. Risk: Bolting precursors. Losses: 10-15% cumulative.

- June (Early Storage: High 30.1°C, Low 23.2°C): Pre-monsoon heat (internals 28-32°C) maintains dormancy but increases evaporation (8-12% loss). Good airflow in cylinders limits pockets. Risk: Minor sprouting if necks are uncured. Losses: 5-8%.

- July (Mid-Storage: High 25.9°C, Low 22°C): Monsoon onset; humidity >80% + mild temps (internals 24-28°C) spike rotting (Aspergillus/Botrytis, 20-25% loss). Cylinders’ mesh walls aid drainage but trap moisture if unturned. Risk: 40% damage from the 2025 rains. Losses: 15-25%.

- August (Mid-Storage: High 26.2°C, Low 21.5°C): Peak humidity (85-90%); temps favor pathogens (internals 23-27°C), eroding quality (sprouts emerge >20°C). Ventilation reduces rot by 10% vs. closed units. Risk: Bulk collapse from softening. Losses: 10-20%.

- September (Late Storage: High 27.5°C, Low 20.7°C): Easing rains but lingering damp (internals 22-26°C); desiccation rebounds post-monsoon (5-10% loss). Cylinders excel here for drying. Risk: Secondary rots if not graded. Losses: 8-15%.

- October (Storage End: High 29.7°C, Low 20.4°C): Drying trend (internals 25-30°C) preserves resale quality, but early heat waves (as in 2025) cause 10% shrinkage. Risk: Export rejection (>5% defects). Losses: 5-10%; total cycle 30-50% without upgrades.

Overall: Pabal’s warmth suits ambient storage better than colder regions, but climate shifts (e.g., +1-2°C warming) amplify losses to 40% (vs. 20-30% baseline). Shift to evaporative-cooled cylinders or cold chains for <20% losses.

Based on the above losses, I made a flow chart to show the possible losses-

Which are the % loss in the all cycle in the storage of the unit if we maintain the inside temperature at 25-300C then the % loss are as follows –

- Onions release just enough moisture to stay physiologically active (avoid sprouting),

- But not enough to lose significant weight or dry out.

That balance usually happens at:

Temperature: 25–30 °C

RH: 65–75 %

At this point:

- Weight loss ≤ 0.2 % per week (acceptable).

If RH falls below 60 %, ΔPv rises and weight loss accelerates.

If RH exceeds 80 %, ΔPv reverses in some zones → condensation → rot.

A small moisture loss (2–4 %) actually helps onions store better:

- It tightens the outer scales, forming a dry, papery protective layer.

- It reduces respiration rate, lowering metabolic activity.

Completely eliminating weight loss could keep the outer layers too moist, encouraging sprouting or fungal decay.

So in well-managed systems, we control, not eliminate, vapor pressure dif

After consulting with Prasad Sir he advises me to focus on the volume of the shape

| Height (H) | Diameter (D) | Height (H) | Diameter (D) |

| 1.0 m | 1.6 m | 3.28 ft | 5.25 ft |

| 1.5 m | 1.3 m | 4.92 ft | 4.27 ft |

| 2.0 m | 1.1 m | 6.56 ft | 3.71 ft |

| 2.5 m | 1.0 m | 8.20 ft | 3.31 ft |

Based on this, find the possible ways to optimize the temperature and humidity at 250C -300C °C and 65-75% respectively.

For the 1000kg of onion:

| Measurement | Value |

| Mass to Hold | 1000kg |

| Height | 5 ft (1.524 m) |

| Diameter | 4.24ft (1.29m) |

13th–19th October

I began researching various ventilation systems suitable for small to medium onion storage structures. One traditional method I studied involves the use of sutli bora (jute or mesh-based bagging systems) to facilitate passive air movement and minimize channel formation.

26th October

We had a review meeting to assess the current stage of the project and identify next steps for experimentation.

28th October

A technical discussion was held on maintaining humidity and ventilation through forced air circulation. The main topic centered on how air pockets or channels form inside the structure and how these can be minimized.

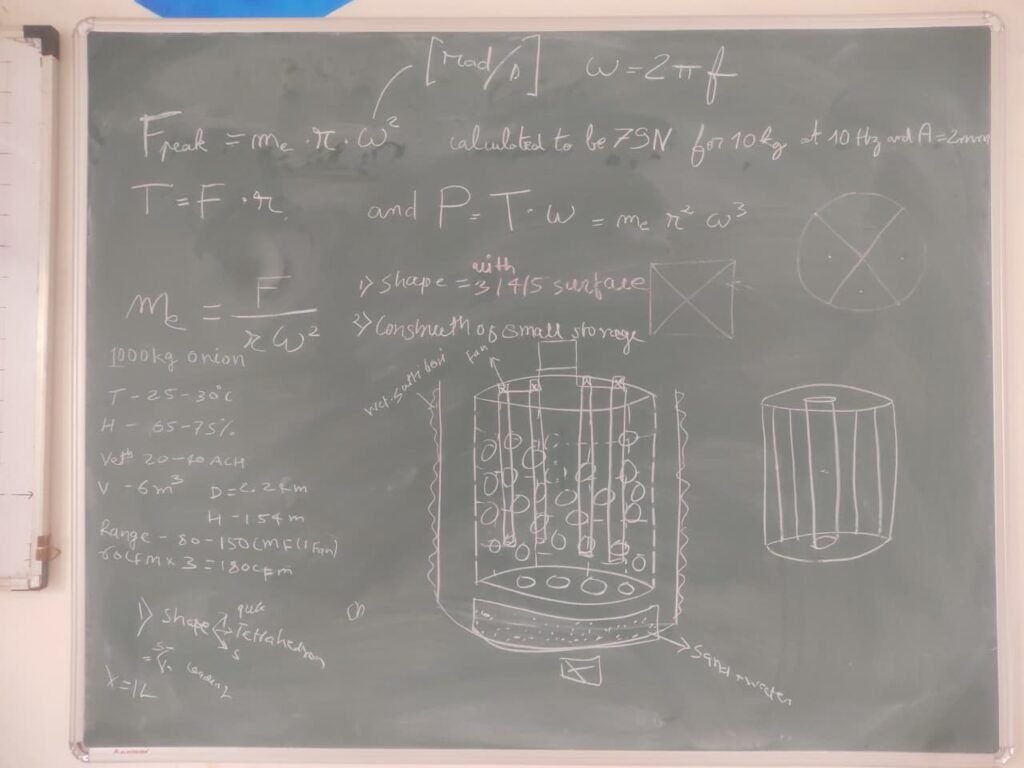

We agreed to construct a small prototype unit to experimentally visualize air pocket formation using fog trials. Additionally, I began researching the surface-to-volume ratio for different structural geometries—cube, tetrahedron, and cuboid—to determine which design offers maximum storage volume with optimal airflow.

Volume Calculations for Target Mass = 5 kg

| Bulk Density (kg/m³) | Required Volume (m³) | Equivalent Volume (L) |

|---|---|---|

| 600 (loose packing) | 0.00833 | 8.33 L |

| 700 (tight packing) | 0.00714 | 7.14 L |

Recommended Cylindrical Prototype Dimensions:

- Diameter = 220 mm (0.22 m)

- Height = 220 mm (0.22 m)

- Volume: ≈ 0.00836 m³ (8.36 L)

- Mass (ρ = 600): ≈ 5.02 kg

- Mass (ρ = 700): ≈ 5.85 kg

Alternative Compact Design:

For tighter packing (700 kg/m³), Ø = 209 mm × H = 209 mm gives a closer 5 kg equivalent volume.

Packing Density and Equivalent Dimensions:

| Density (kg/m³) | Diameter = Height (m) | Diameter (mm) | Inches |

|---|---|---|---|

| 600 | 0.1619 | 161.9 | 6.37 in |

| 650 | 0.1576 | 157.6 | 6.21 in |

| 700 | 0.1538 | 153.8 | 6.05 in |

D = H = 0.158 m (158 mm ≈ 6.2 inches)

29th October

Constructed a small test structure with a diameter of 8 inches and a height of 17 inches to visualize airflow. When I presented it to Dixit Sir, he advised increasing the diameter to at least 15 inches to observe better air distribution.

30th October

Built a larger prototype with a diameter of 16 inches for further testing and modifications.

31st October

Conducted trial runs on both small and large structures, with and without fog (dhur), to study airflow behavior.

1st November

Presented the large storage unit to Dixit Sir and Prasad Sir. During the demonstration, Fog-Dhur Sir suggested testing the unit with fog visualization since the anemometer readings were too low to detect air velocity changes. The fog test would visually confirm airflow inside the structure.

3rd November

Performed fog trials on the large storage unit using the fog-dhur system to visualize airflow and identify stagnant regions.

4th November

Presented the fog trial results to Dixit Sir. The test was conducted using 13 kg of onions. Sir noted that air circulation was now moderate and visible. He advised focusing next on optimizing the ventilation layout, suggesting two possible configurations

- Forced air inlet either from above or below the structure.

- Exhaust air outlet either from above or below the structure.

These design choices will be tested in the next phase to determine the most effective configuration for maintaining temperature and humidity equilibrium.

7 November – Exploring Airflow Through Fluid Dynamics

I began the week by diving into the science behind airflow movement inside an onion-filled chamber. To understand how air travels through such a dense onion bed, I used Darcy’s Law, which describes how fluids flow through porous materials.

Q=kAΔP/μL

Breaking this down helped me visualize why airflow behaves differently in small and large storage units. When the onion bed is shallow (small L), even a small suction force creates enough airflow. But as the height increases, the system becomes more resistant, requiring a stronger pressure difference.

This is precisely why large commercial onion storage systems rely on supply fans; they push air more effectively than extraction setups. Understanding this theory gave me clarity before jumping into physical trials.

8 November – Fixing the Fan-Pipe Connection

To improve the system’s airflow, I needed to connect a 50 mm pipe to a 180 mm fan. After discussing the challenge with Abhijeet Sir, he suggested using a reducer to make the connection stable and functional.

I bought the reducer and prepared it for integration. This small component is crucial because improper air channeling can significantly impact airflow uniformity

11 November – Building the Stand & Preparing for Realistic Testing

I constructed the stand for the large storage unit and created a fixed setup for the pipe. While discussing the testing plan, Prasad Sir suggested that instead of empty trials, I must load the system with actual onions to replicate real conditions—air resistance, pocket formation, and overall performance.

This advice shifted my focus toward more realistic experimentation.

12 November – Fog Visualization: Understanding Air Pockets

To observe airflow in real-time, I built a fog-based system using “Ud”. This was one of the most revealing experiments so far.

What I observed:

- When air was supplied into the chamber, the fog moved smoothly through the onions with fewer air pockets.

- When air was extracted, it created clusters of stagnant pockets, and in some areas, the air barely moved.

Both Dixit Sir and Prasad Sir recommended sorting the onions and conducting further trials for more accurate results.

13 November – Grading Onions & Running Comparative Trials

I spent this day sorting onions into three size categories:

- Small (40–55 mm)

- Medium (55–60 mm)

- Large (> 60 mm)

After sorting, I ran trials using both air supply and air extraction.

This time, the differences were even clearer:

- Extraction created more pockets and inconsistencies.

- Supply still performed better, creating fewer pockets and more uniform airflow.

This reinforced the earlier theoretical results from Darcy’s Law.

14 November – Experimenting With Peripheral Suction

To push the experiment further, I designed a new structure to hold the fan at the center and tested a peripheral suction system.

The aim was to address airflow imbalances and understand whether suction from the periphery could counter the pocket formation seen earlier. This experiment opened up new directions for improving system design.

15-17 November 2025 – Farmer Outreach for Onion Trials

I began the week by searching for farmers who could support our onion storage trials with at least 500 kg of onions. This step is crucial because large-scale trials will help validate the ventilation design, moisture control, and heat-management strategies we are developing.

19 November 2025 – Onion Storage Discussion with e-Yantra Students

I had a detailed discussion with the e-Yantra student team about the onion storage unit. We explored critical parameters such as CO₂ accumulation, heat transfer, and internal thermal gradients factors that directly influence rotting and shelf life.

20 November 2025 – Ideation & QFD Introduction

Ideation continued with the e-Yantra team under the guidance of Dixit Sir, who introduced us to the MIT lecture on QFD (Quality Function Deployment).

QFD, developed in Japan in the late 1960s, is a structured method to transform customer needs into technical specifications. He also explained the Fishbone (Ishikawa) Diagram and the 6M framework, which helps identify root causes affecting system performance:

- Manpower – Skills, training, human involvement

- Machine – Equipment and tools

- Material – Raw materials and inputs

- Method – Processes and procedures

- Measurement – Testing and inspection

- Mother Nature (Environment) – Weather, temperature, humidity

This session clarified how systematically these tools can be applied to our onion storage design.

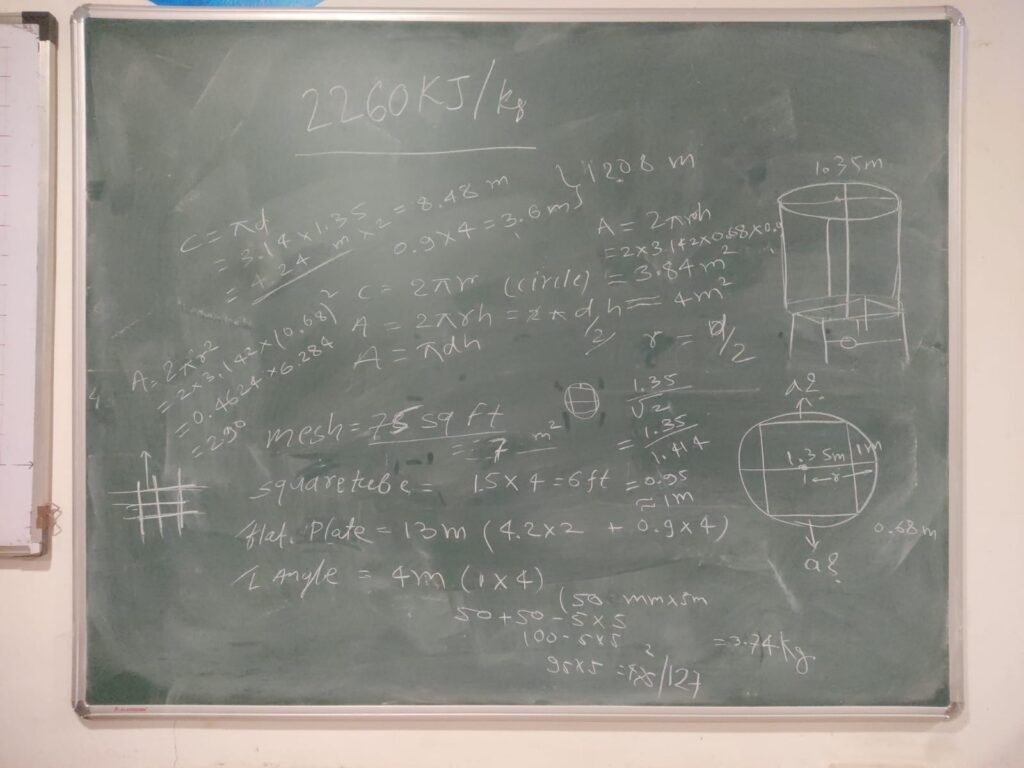

24/11/22 – Calculated the mesh requirement for the proposed 500 kg onion storage unit.

For a height of 0.90 m, the volume was estimated as ≈1.2883 m³ (≈45.49 ft³), and for a height of 1.00 m, the volume increased to ≈1.4314 m³ (≈50.55 ft³).

10–14 December 2025 – Participated in the Kisan Exhibition, Pune, where I showcased the onion storage unit to gather direct feedback from farmers. Key suggestions included making the storage sections detachable to allow easy removal of spoiled onions and designing scalable units to cater to varying farmer requirements.

29/12/25 – Finalized a detailed material list based on structural needs, including mesh, square tubes, L-angles, and plate patti.

30/12/25 – Procured the required materials from the local market. An AI-generated reference image was used to guide the fabrication process.

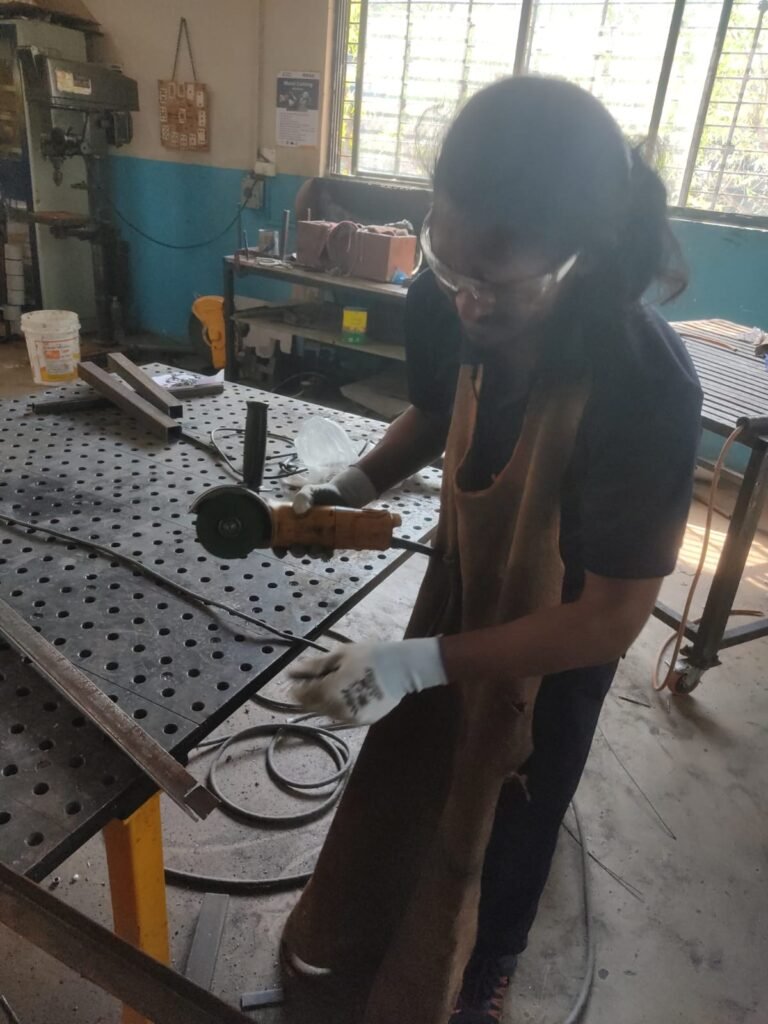

31/12/25 – Began fabrication by forming the circular ring structure, followed by constructing a table base to support the unit.

01/1/26 – Faced challenges in achieving a perfect circular structure due to limitations of the circular gauge; however, the structure was manually adjusted and completed.

02/1/26 – Completed the circular frame and table structure. After consulting with Abhijeet, it was concluded that the existing base might not safely support a 500 kg load. To address this, four additional support legs were added to the lower section to enhance structural stability.

03/12/25

- Circular ring fixation was carried out on a stable table using welding to ensure structural rigidity of the onion storage unit frame.

05/01/26

- Continued welding work on the circular ring structure to complete the main supporting frame of the storage unit.

06/01/26

- Visited Dadabhau Jadhav to request 500 kg of onions for storage trials.

- He declined, stating that Kharif onions are not suitable for long-term storage and questioned the purpose of using them.

- Subsequently contacted Sandip Thorve, who agreed to provide 500 kg of onions.

- Noted that onions require 3–4 days of field curing before storage to reduce surface moisture.

07/01/26

- Worked on duct placement design inside the onion storage unit to ensure uniform and efficient air ventilation throughout the onion bulk.

- On duct placement I manage to press it in lower end as the opening of pine with respect to fan diameter.

08/01/26

- While working on duct installation, Yashwant Sir asked about the CFM (Cubic Feet per Minute) requirement of the fan.

- Initially discussed a 1000 CFM fan, after which I recalculated the actual airflow requirement using onion volume and porosity-based calculations.

Assumptions

- Average onion diameter = 5 cm

- Radius, r = 2.5 cm = 0.025 m

- Average onion weight = 60 g

- Total onion mass = 500 kg

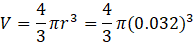

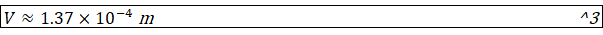

Volume of One Onion (Sphere Approximation)

V=34πr3 V=34π(0.025)3 V≈6.54×10−5 m3

Number of Onions

500 kg=500,000 g Number of onions=60500,000≈8,333 onions

Total Solid Onion Volume

Vsolid=8,333×6.54×10−5 Vsolid≈0.545 m3

Practical Bulk Volume (Including Air Gaps)

Assuming bulk packing efficiency of 60–65%:Vbulk=0.60 to 0.650.545 Vbulk≈0.84 to 0.91 m3

Void (Air) Volume

Vp=Vstructure−Vonions Vp=1.88−0.545=1.335 m3

Porosity Calculation

ε=VtotalVp ε=1.881.335=0.71

Summary Table

| Parameter | Symbol | Value | Unit | Remarks |

|---|---|---|---|---|

| Total structure volume | V_structure | 1.88 | m³ | Cylindrical storage unit |

| Solid onion volume | V_onions | 0.545 | m³ | Based on 5 cm, 60 g onions |

| Void (air) volume | V_p | 1.335 | m³ | V_structure − V_onions |

| Total volume | V_total | 1.88 | m³ | Same as structure volume |

| Porosity | ε | 0.71 | – | Indicates high airflow space |

Fan Selection Verdict

| Fan Capacity | Verdict |

|---|---|

| 50–80 CFM | Ideal |

| 100–120 CFM | Acceptable |

| 600 CFM | More than sufficient |

Conclusion:

The 600 CFM fan selected for the onion storage unit provides adequate and excess airflow, ensuring effective ventilation and moisture removal.

09/01/26

- Deployed the onion storage unit at Sandip Thorve’s house for the storage trial of 500 kg onions.

10/01/26

Onions are placed in the house of Sandip Thorve.

But the calculations were wrong so the Stucture multiply by 2X. Now, the structure can accomodate for 1000kg of onions.

500kg of onions been placed for the remaining 500kg nwwd to wait for cultivation in Sandip Thorve farm.

14 January 2026

Visited the onion storage facility of Sandip Thorve. Data Loggers are waiting for the completion because of the Code problem in CO2 and H2S gas detection.

24 January 2026

Interacted with local farmers for the availability of onions for trials in a 1000kg structure. Out of 8 farmers, 6 were available on call, and I visited their onion farm for a field visit.

27 January 2026

Unfortunately, farmers were not very supportive of the onion trials on their own 1000kg onion storage unit, so we decided to build two structures with a 30kg onion capacity for comparison due to the unavailability of onions. Received guidance from Prasad Sir regarding the importance of setting a project timeline.

28 January 2026

Procured onions from Raju Mama of 56kg at a rate of 15 rupees per kg total of 840 rupees. Measured and recorded the weight of the onions. Coordinated with Sandip Thorve regarding storage arrangement and the unloading of onions from the structure, because he wants to sell the onions. As he is selling all of his onions we need to see other farmers for the trials basis for 1000kg. ,

29 January 2026

Two onion storage structures of 30kg capacity were made for a comparative study to understand the effectiveness of ventilation. One is attached to a fan below the structure, and three data loggers are in three different positions, lower, middle, and above the level of the structure. But due to Code problems, the new data loggers are not working, so I attached two data loggers to the structure.

Now we are getting only the value of Temperature and humidity, still waiting for the resolution in the code of the new data logger’s problems.

Installed the two onion storage units in the Agriculture Department of Vigyan Ashram.

One has a 30kg with data loggers

One doesn’t have any data loggers.

3/2/2026

Dixit sir gave me a question about the structure of the onions storage unit, why we are choosing only a cylindrical structure.

To decide the shape of the structure, I gather information about the different shapes.

As Prasad Sir advises me to analyse shapes i have to decide on any two parameters. I take the capacity of 1000kg, and height is 1.2m, with a bulk density of 550kg/m^3. By putting these values, I start to compare shapes.

| Parameter | Cylindrical | Cuboid (square) | Rectangle (2:1) | Tetrahedron |

|---|---|---|---|---|

| Volume constraint | ( \pi r^2 h = 1.82 ) | ( a^2 h = 1.82 ) | ( 2w^2 h = 1.82 ) | ( \frac{1}{3}A_b h = 1.82 ) |

| Simplified size | ( r=\sqrt{\frac{1.82}{\pi·1.2}}=0.70 ) m | ( a=\sqrt{\frac{1.82}{1.2}}=1.23 ) m | ( w=\sqrt{\frac{1.82}{2·1.2}}=0.87 ) m | ( A_b=\frac{3·1.82}{1.2}=4.55 ) m² |

| Dimensions | D = 1.40 m, H = 1.20 m | 1.23 × 1.23 × 1.20 m | 1.74 × 0.87 × 1.20 m | Equilateral triangular pyramid: a = 3.24 m, H = 1.20 m |

| Cross-section area A | ( \pi r^2 = 1.54 ) m² | ( a^2 = 1.51 ) m² | ( lw = 1.51 ) m² | ( A(z)=A_b(1-\frac{z}{H})^2 ) |

| Perimeter P | ( 2\pi r = 4.40 ) m | ( 4a = 4.92 ) m | ( 2(l+w)=5.22 ) m | ( P(z)=3a(1-\frac{z}{H}) ) |

| Hydraulic diameter | ( D_h=\frac{4A}{P}=1.40 ) m | 1.23 m | 1.16 m | ( D_h(z)\rightarrow0 ) |

| Bottom stress σᵥ | 4.7 → 2.3 kPa effective | 3.8 kPa | 4.6 kPa | 6.5 kPa |

| Onion damage verdict | Safe | Marginal | Unsafe | Failure |

| SA/V ratio | 4.6 m⁻¹ | 5.3 m⁻¹ | 5.8 m⁻¹ | 6.4 m⁻¹ |

| Stress concentration factor | ≈1.0 | 1.4–1.6 | 1.7–2.0 | →∞ |

4/2/26

On the above table information, when I start explaining to the PRASAD sir, it seems it was unconvincing for the actual question- why we will choose only cylindrical?

Sir again advises me to check the pressure distribution in the shapes.

7/2/26-

Today I discussed with Prasad Sir on the Shape of the structure, where I drew QFD for an onion shape based on the following parameters-

- Loading / Unloading

- Cleaning

- Fabrication

- Cost

- Air ventilation

- SA/V

The QFD is as follows –

| Importance-Rating | H – 9 | M- 3 | L- 1 | H- 9 | H-9 | H-9 | H-9 | Total=∑(Rating×Importance) |

| Parameters | Loading | Unloading | Easy to clean | Fabrication | Cost | Air Ventilation | SA/V | Total |

| Structure | ||||||||

| Cylindrical | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 245 |

| Cuboid | 5 | 5 | 4 | 4 | 4 | 3 | 4 | 199 |

| Tetrahedron | 4 | 3 | 3 | 3 | 2 | 1 | 3 | 129 |

The calculation for this table is as follows-

Importance – The 1-5 numbers in the shape parameters numbers

- Low

- Considerable

- Medium

- Good

- Best

Rating-– It represents the overall acceptance of the shape. Importance = High (more important), Medium (we can think about it), Low (does not matter that much).

- H = 9

- M = 3

- L = 1

Total=∑ (Rating × Importance

As the QFD suggests, the calculations of the cylindrical shape dominate with 245 points, while the cuboid and tetrahedron have 199 and 129 points, respectively.

So, from now we will proceed with the cylindrical shape of the onion structure.

I discuss the parameters of the CFM of the fan and pipe diameter for better circulation.

The sizes are given by – Height- 4ft, Diameter – 3.2ft, and

Volume occupied by these dimensions – 32ft3 in m3–m3

8/2/26-

In the discussion with prasd sir gave me the task to calculate the CFM of the fan and the diameter of the fan

For the CFM of the fan, it is essential to calculate the following questions-

- In 1 kg of onions, how many onions are there?

- If so, how many onions are present in 500kg of onions?

- How much volume does 500kg of onions?

- Porosity= Vtotal – Vonions. (ft3)

- So we have Volume of the air (Vp) to be removed in 1 hour = 30*porosity

- CFM=Vp/60= ???

I measured the number of onions in 1 kg of onions. For this, I took three samples of onions it gives 11, 11, and 13 onions per kg. So the number of onions present in one kg is 12.

Diameter = 64 mm = 0.064 m

Radius = 0.032 m

Volume (onion ≈ sphere):

- Volume of 1 onion =

- Onions per kg = 12

- Total mass = 500 kg

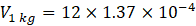

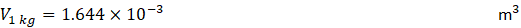

Volume occupied by onions in 1 kg

Volume occupied by onions in 500 kg

Now the porosity is given by –

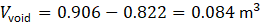

Vvoid=Vtotal−Vonion

So the air needed to pass or remove inside the structure is only 0.084m3, but the pressure head is more; here we need to calculate that.

9/2/26

Today I search about the pressure loss caused by the air to calculate the CFM of the fan.

The pressure loss is due to the following reasons-

- Opening of the pipe with a fan.

- Opening of holes in the pipe.

- Onion resistance inside the mesh.

And other pressure too!

So for the decision matrix, we have to combine all the pressure head losses.

For the design, Prasad sir told me to create it on CAD software with the help of Yashwant or Abhijeet sir.

I created a BOM for the material to fabricate the 500kg onion storage structure, and I need to clear the clearance to buy it. In the review meeting, Yogesh sir advises to fabricate the structure while finding the right CFM for the Fan.

In the conversation with Dixit sir, I told him to fabricate the structure while we figure out the CFM of the fan. Sir gave me a green signal on it, so tomorrow I will go to buy the material with permission for the structure.