OBJECTIVE

To design an integrated solar and inverter system to power the blower of a biomass gasifier and evaluate the techno-economic feasibility for clean cooking in rural areas.

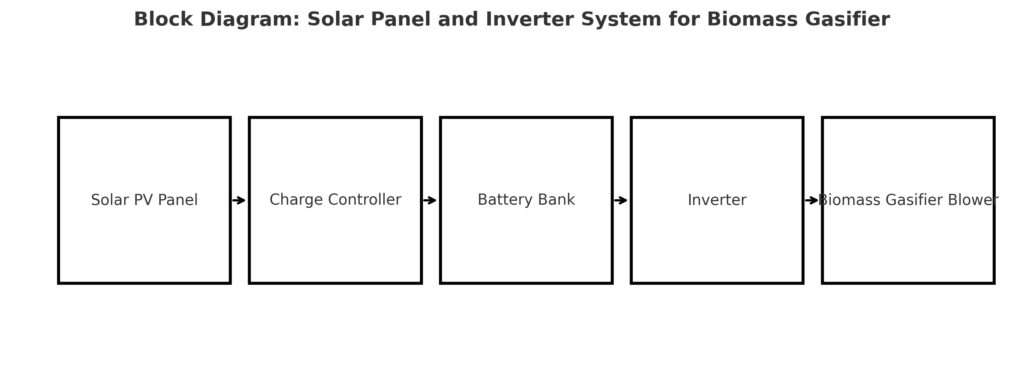

Week 1 – Understanding initial system design and performed technical calculations for solar panels, inverter and battery.

What is a Biomass Gasifier?

A biomass gasifier is a device that converts solid biomass (like wood, crop waste, coconut shells, etc.) into a combustible gas called syn gas through a process called gasification.

It’s a cleaner and more efficient alternative to directly burning biomass.

How does it work?

A biomass gasifier performs partial combustion of biomass in a controlled oxygen environment.

Step-by-Step Process:

- Feed Biomass (wood chips, shells, crop husk, etc.)

- Ignite it in the combustion chamber (usually with a small amount of fuel or fire)

- Due to limited oxygen, it doesn’t fully burn — instead, it breaks down into gases like:

- Carbon monoxide (CO)

- Hydrogen (H₂)

- This gas is called syngas

- The gas is filtered and cooled, then used as fuel for:

- Cooking

- Electricity generation

- Heating

What is the Function of a Gasifier?

Convert solid waste into usable energy

Produce clean-burning gas from agricultural waste

Reduce dependency on LPG, diesel, or firewood

Why it’s useful for rural areas ?

- Uses locally available biomass

- Reduces LPG/firewood use

- Creates cleaner combustion

- Can work with solar for hybrid systems

- Low-cost and sustainable in the long run

Gasification Process

Gasification is a thermochemical process that converts solid fuels (like biomass, coal, or wood) into a combustible gas mixture, called producer gas or syngas, by partially burning it in a controlled environment with limited oxygen.

Biomass (CₓHᵧOₙ)+Limited O₂→CO+H₂+CH₄+Heat

CALCULATIONS

Energy needed per day

Blower of the gasifier is of 1 HP = 746W

Operating time = 4 hours

Energy needed per day = 746W*4 = 2984 WH = 3KWH / day approx

Capacity of inverter

746*2 (surge) = 1492 W = 1.5 – 2KW capacity

Solar PV Capacity

Load = 3KW

Solar hours = 5 hours/day

Assuming 30% loss factor

Solar panels never operate at 100% efficiency due to several real-world losses. To compensate for these losses we multiply by 1.3 (or 30% extra).

Dust and dirt on panels = 5-10%

Panel aging and temperature effects = 5-10%

Inverter and wiring losses = 5-10%

Shading, angle efficiency = 5-10%

Total losses = 25-30% so we multiply by 1.3

PV Capacity = (3000/5)*1.3 = 780W *1.3 = 1.2KW approx

Battery Capacity

4 batteries of 12 V

Ah = 3000/48 = 62.5 Ah

Lead acid batteries are discharged to 70-80% ( depth of discharge)

Thus 62.5/0.7 = 89.3 Ah = 100 Ah

So we’ll consider 4 batteries of 12V and 100 Ah

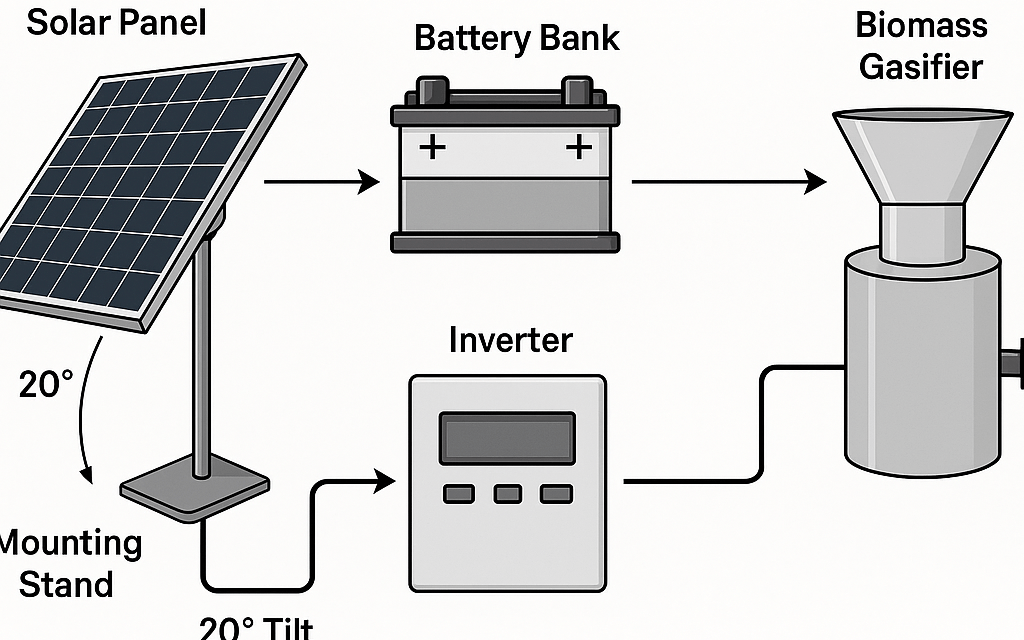

Tilt angle

18 to 20 degree facing due south ( latitude of Pabal = 18.7 degree N )

Week 2 – Economic analysis and market survey

Battery back up duration

Blower is of 1 HP

Battery is of 48V and 100 Ah

E = V*Q

= 48*100 = 4800Wh = 4.8 KWH

Safe discharge = 60 – 70 % = 65 %

4.8 * 0.65 = 3.12 KWH usable energy

Back up time = 3.12 KW/ 0.746 KW

= 4.18 hours = 4.2 hours

SAVINGS

Blower = 1 HP = 746W

Usage = 4 hours/day

Daily energy required = 746*4 = 2.984 = 3KWH/day

Monthly power savings = 3KWH/day * 30 = 90 KWH/month

Annual power savings = 90*12 = 1080 KWH/year

If blower runs on grid electricity :

India’s grid emits about 0.713 kg of CO2 per KWH

1080KWH/year * 0.82 = 770.04 CO2/year is avoided

If cooking was done using LPG :

LPG in India contains 14.2 Kg of LPG

1Kg of LPG = 3Kg of CO2

C3H8 + 5O2 = 3CO2 + 4H2O

Molecular mass of Propane = 44g/mol

Amount of CO2 = 3*44 = 132 g

44g propane gives 132g CO2

1Kg of propane gives 3Kg of CO2

So 1 cylinder = 42.6 Kg CO2 (14.2 *3 )

If the kitchen uses 2-3 cylinders per month , yearly usage is approximately 30 cylinders.

30*42.6 = 1278 Kg CO2/year from LPG

Grid electricity for blower = 770.04 Kg CO2

LPG cooking fuel = 1278 Kg CO2

Total = 2048.04 CO2/year

Savings

Grid electricity = 8-10 rupees per KWH

So 1080 KWH/year * 8 = 8640 = 9000 rupees per year approx

1 LPG cylinder of 14.2 Kg costs = 852.5

Assuming kitchen uses 2-3 cylinders per month

So, annually 2.5*12 = 30 cylinders

30*852.50= 25,575

Therefore, total savings = 25,575 + 9000 = 34,575 per year

Pay back period

Total investment / Annual savings = 1,50,000/34,575 = 4.33

Pay back period = 4-5 years

BIOMASS GASIFIER

Cost Breakdown for 1.5 kW Solar + Inverter System

| Component | Specification | Quantity | Unit Price (₹) | Total Cost (₹) |

|---|---|---|---|---|

| Solar PV Panels | 300 W, Monocrystalline | 5 panels | ₹7,500–₹8,000 | ₹37,500–₹40,000 |

| MPPT Charge Controller | 48 V, 60–80 A, solar-grade | 1 unit | ₹6,000–₹8,000 | ₹6,000–₹8,000 |

| Pure Sine Wave Inverter | 2–3 kW, 48 V hybrid inverter | 1 unit | ₹18,000–₹22,000 | ₹18,000–₹22,000 |

| Battery Bank | 12 V, 100Ah tubular lead-acid | 4 batteries (48 V) | ₹9,000–₹10,000 | ₹36,000–₹40,000 |

| Installation & Cabling | Wiring, mounting, labor, fuses | Lump sum | — | ₹10,000–₹12,000 |

Total cost ( including GST and transportation) = 1.2 – 1.5lakhs

Week 3&4 – Conducted financial assessment via dealer quotations.

Actively communicated with multiple solar equipment dealers to collect quotations, compare prices, and finalize three shortlisted options for the solar panel and inverter system.

Comparative Analysis of the three quotations received