INTRODUCTION

A solar dome dryer is an energy-efficient device used for drying agricultural products, herbs, spices, fruits, vegetables, and even fish or meat. It harnesses solar energy within a specially designed dome-shaped structure to create a greenhouse-like environment that accelerates the drying process.

Key Features

-Passive Solar Energy Use: Operates without the need for electricity or fuel.

-Uniform Heating: The dome shape helps in even heat distribution.

-Hygienic Drying Environment: Protects products from dust, insects, and contamination.

-Portability: Many models are lightweight and easy to move.

-Scalability: Suitable for small-scale farmers or scaled-up for commercial use.

Advantages

- Reduce post-harvest losses.

- Increases the shelf life of dried products.

- Environment friendly with zero carbon emission.

- Low operating costs and minimal maintenance.

26/03/2025

After thoroughly cleaning both the interior and exterior of the solar dome dryer to ensure it was free from dust and any residues from previous use, I proceeded to prepare for the upcoming drying trial. This time, the focus was on drying onions, so I began by organizing the necessary materials and making sure the equipment was ready for optimal performance.

After cleaning the solar dome dryer, we discussed about the onion trials with Prasad Sir. He instructed us to check the thickness of the onions and the quantity of onions per sq.ft.

After discussion, we cut the mesh into 15 pieces, each measuring 20sq.cm, to prepare the samples for placement in trays.

We measured 1 sq. cm on the tray to estimate how many onions would fit in 1 sq. ft.

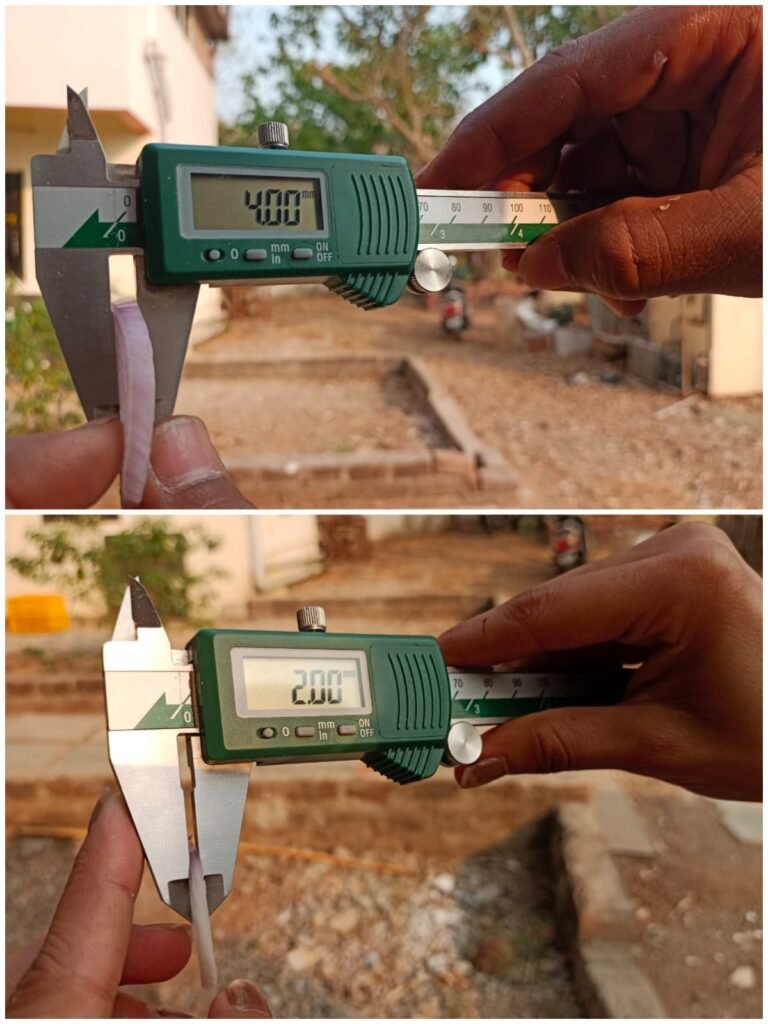

Then we measured the thickness of the onion using a vernier caliper and used two types of slicing plates to measure the thickness:

- The first plate had a thickness of 2 mm

- The second plate had a thickness of 4 mm

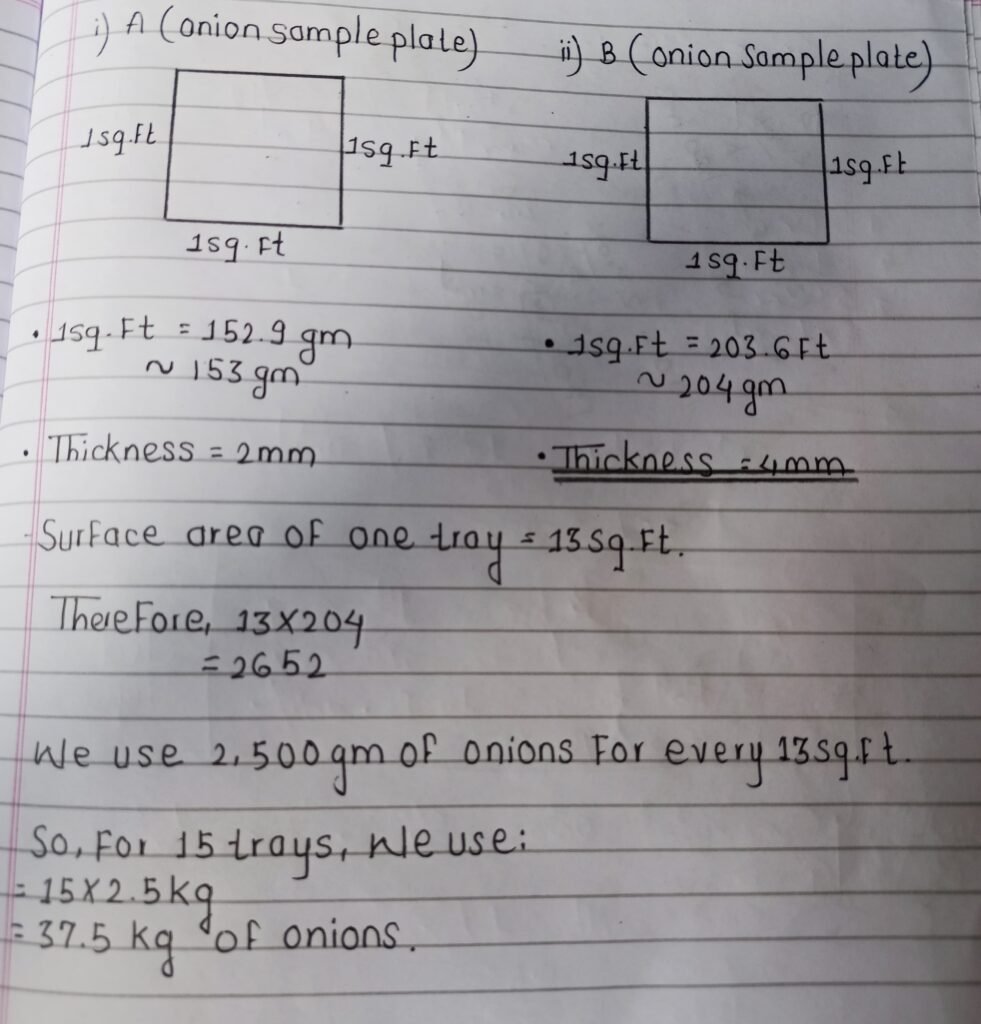

After performing the thickness check, we calculated the amount of onion required per sq.ft. Then using the 2mm slicing plate, 153gm of onion were used, while 204gm were used with the 4mm slicing plate.

Calculation of 1sq.ft by 1sq.ft onion sample.

26/03/2025

After completing the sample trial’s, we cleaned the onion and loaded 44kg of them into the dryer.

Onion drying process followed:

Raw onion selection

(Sorting and inspection)

Cleaning

(Removal of dirt, soil, and outer skin)

↓

Peeling

(Mechanical or manual removal of onion skin)

↓

Slicing/Chopping

(Depending on the desired final product size)

↓

Drying

(solar dome dryer)

↓

Packaging

(Airtight packaging to prevent moisture absorption)

↓

Storage

(In a dry, cool place)

After buying onions, i peeled off their dry outer layers so they will be ready for slicing and dehydrating.

27/03/2025

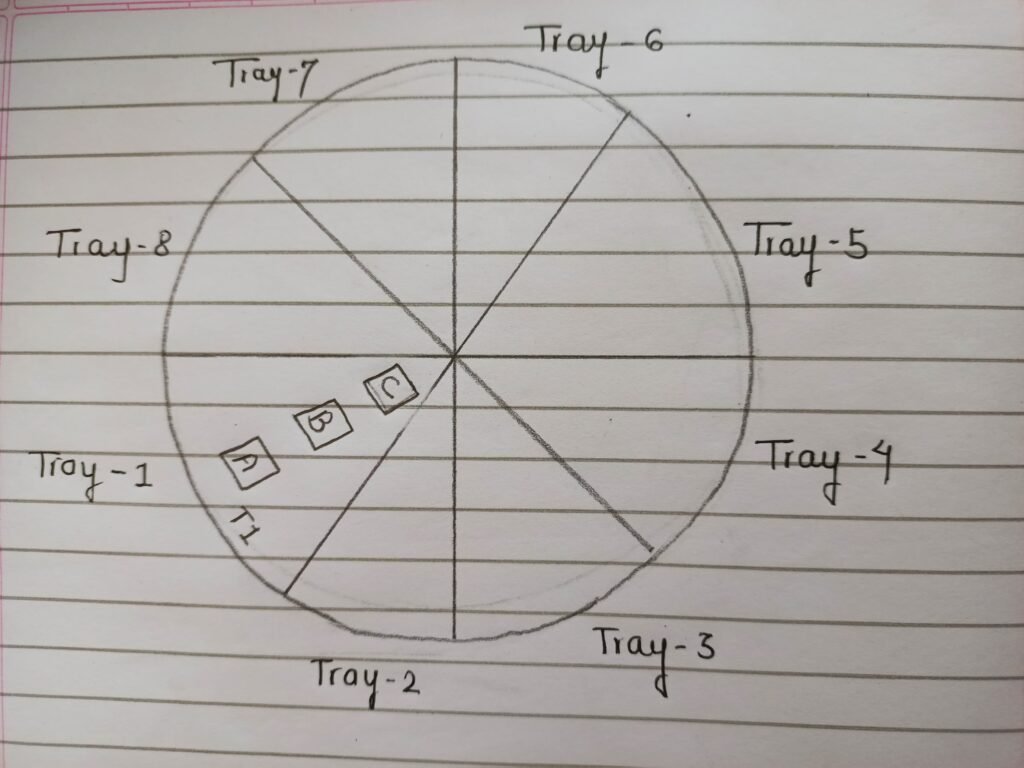

After cleaning we prepared fresh onion slices for the drying process by cutting them into uniform pieces to ensure consistent results. These slices were then placed in one structure of the dryer, where we arranged trial samples labeled A, B, and C and each sample plate place 80gm of onion. Each sample was carefully positioned to monitor and record variations in weight, humidity, and temperature throughout the drying period.

Total initial weight of onions =44kg.

Total loading=37.5kg.

Sample size=80gm.

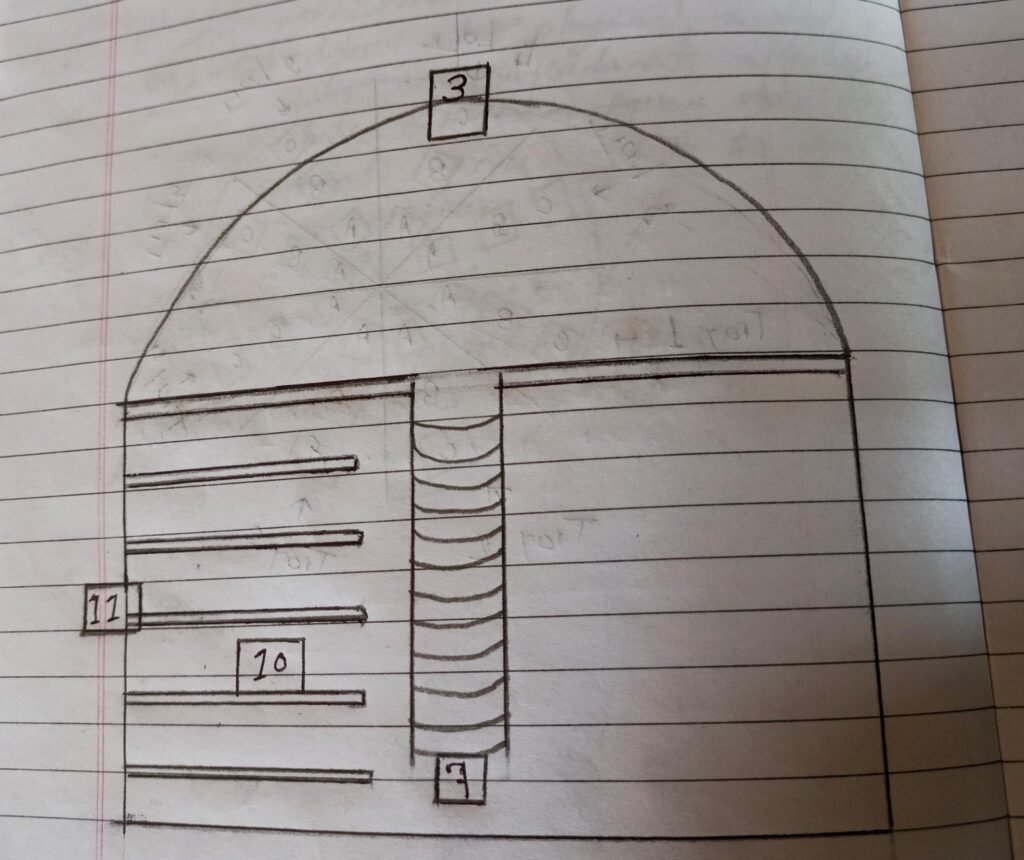

Fig. Dome structure

28/03/2025

We monitored and analyzed temperature and humidity data throughout the day to examine their effect on the drying process and took the readings of the onion sample at 9:00AM and 6:00PM.

Fig. Data logger position

29/03/2025

We monitored and analyzed temperature and humidity data throughout the day to examine their effect on the drying process and took the readings of the onion sample at 9:00AM and 6:00PM.

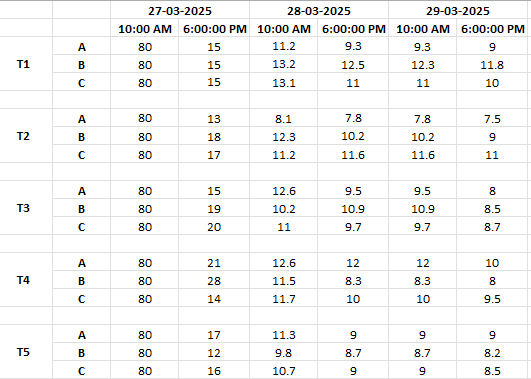

These are the readings collected over 3 days

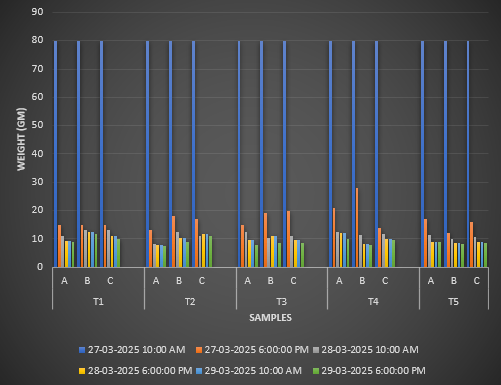

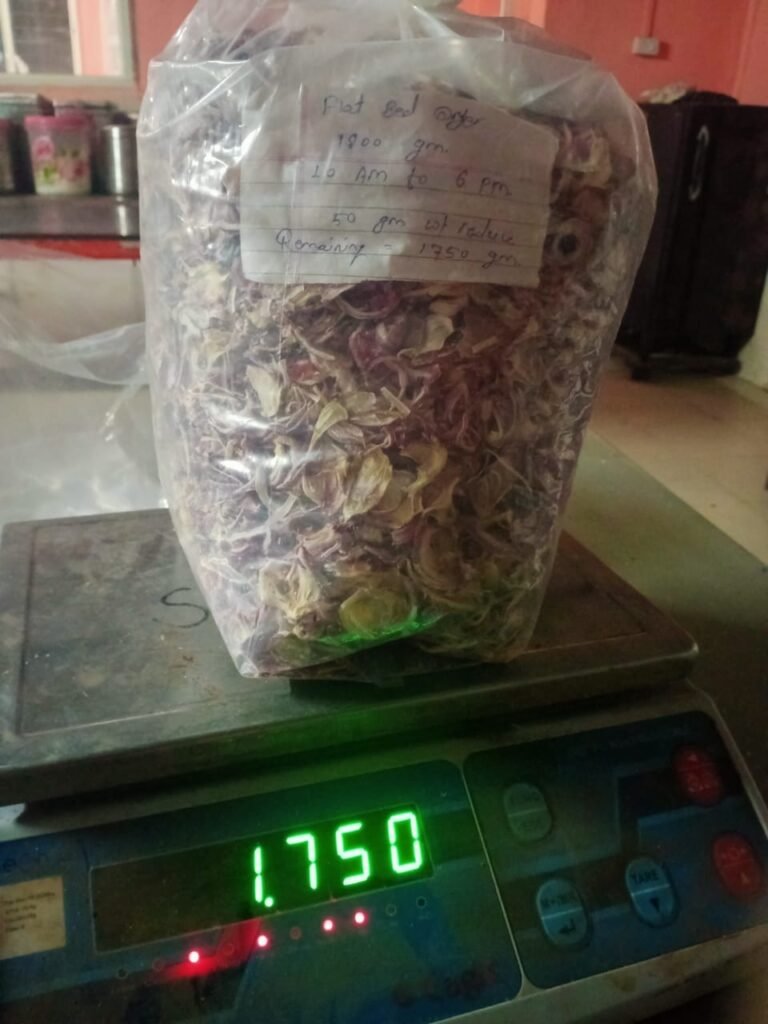

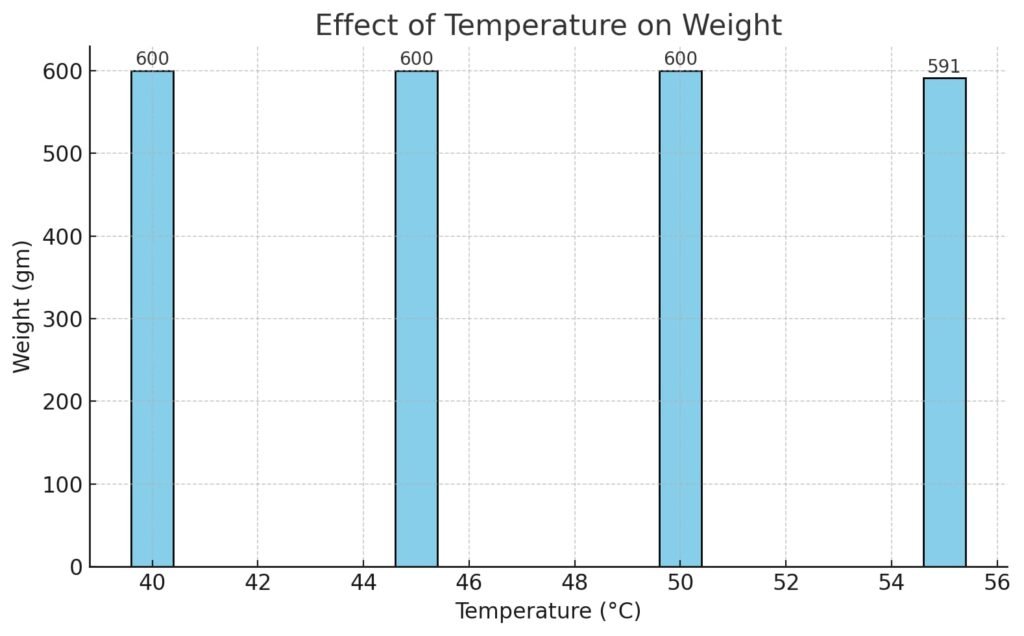

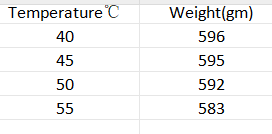

After we took the dried onions out of the dryer, we had a discussion with Dixit Sir, Prasad Sir, and Abhijeet Sir. During the conversation, they gave us instructions on what to do next. They told us to divide all the dried onions into two separate parts. The first part should be put into the electric dryer and dried again at different temperatures — 40, 45, 50, and 55 degrees Celsius. The second part should be placed in the flatbed dryer for further drying.

Total dread onion= 4800gm

Electric dryer= 2400gm

Flat-bed dryer=2400gm.

The weight after it was removed from the flat-bed dryer

The weight after it was removed from the electric dryer.

05/04/2025

We have completed the packaging of dry onions, with each unit containing two packs of 100 grams each, ready for sale.

06/04/2025

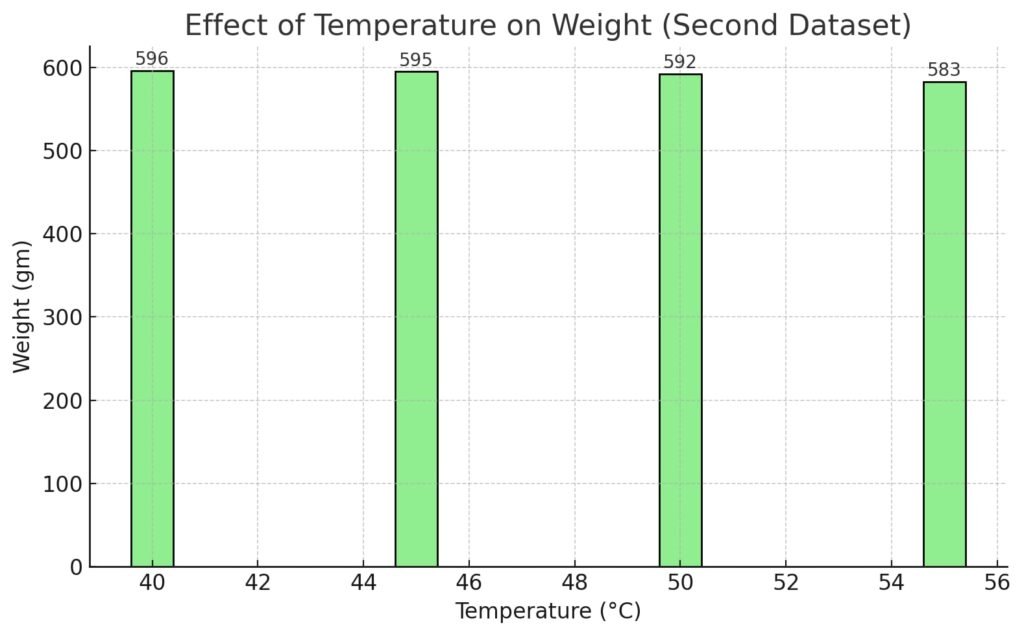

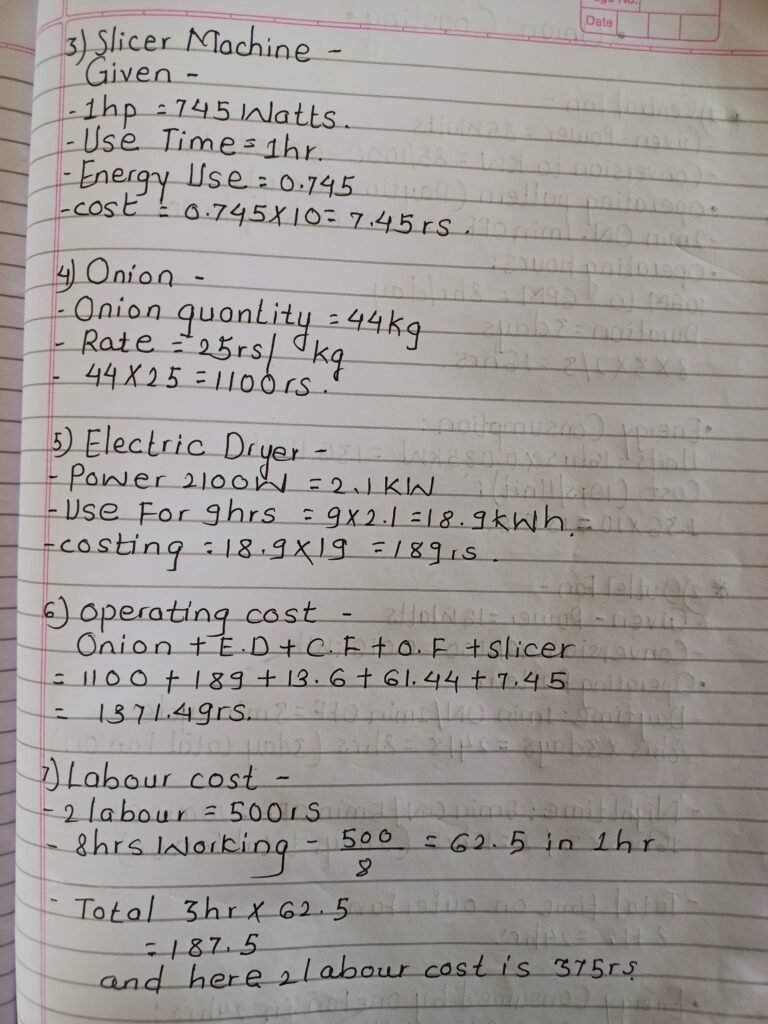

We are trying to find out how much it costs to dry onions by looking at all the things that can affect the process. This includes the cost of the machines used for drying, how much electricity the machine use, how many workers are needed to run them, and how much time it takes to dry the onions. By looking at all these factors, we can better understand the total cost of drying onions.

07/04/2025

We have finished calculating all the final costs and have written down all the details here:

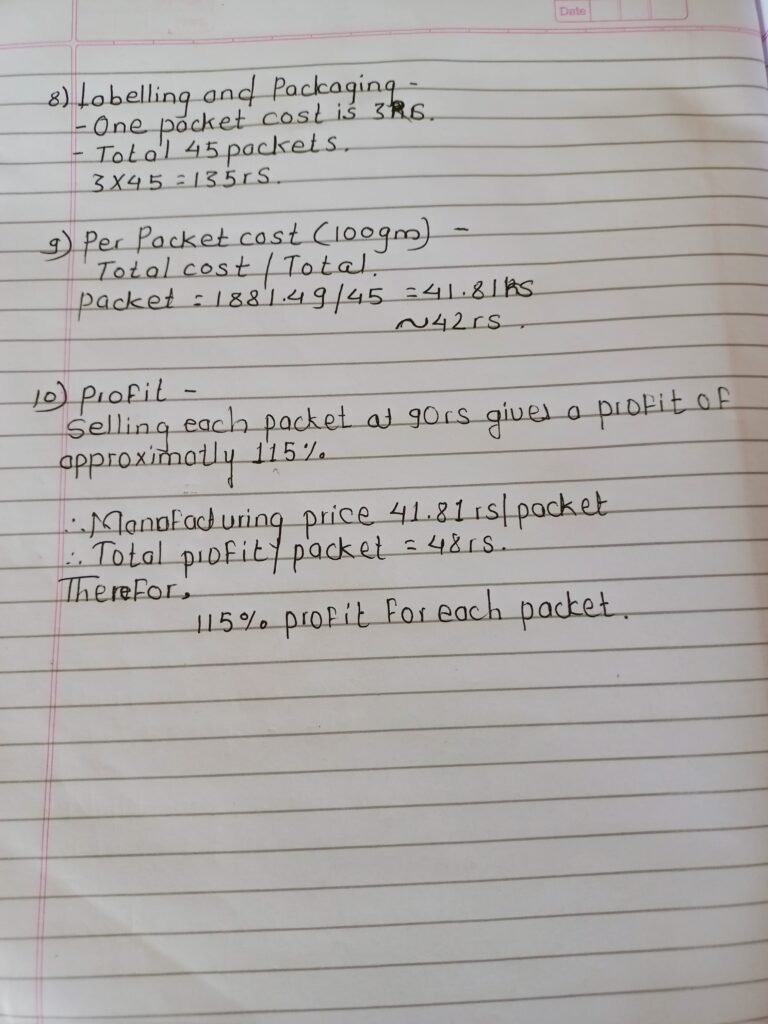

Why have we set the retail price at ₹90 per packet for onion flakes?

Businesses need to make enough profit to keep running in the long term, but not so much that their prices drive away customers. A fair profit helps them survive and still compete with others

Conclusion:

A total of 44 kg of fresh onion slices were dried using a solar dome dryer, with each tray holding 2.5 kg, resulting in 18 trays used. After the drying process, the final dried weight was 4.8 kg. This represents a drying yield of approximately 10.9%, indicating that about 89.1% of the original weight was moisture lost during drying. The solar dome dryer effectively reduced the moisture content of the onions, producing a lightweight, shelf-stable product suitable for storage or further processing.

08/04/2025

We purchased tomatoes for a market trial and are currently in the process of cleaning and sorting them in preparation for drying tests using a dome dryer. This step is essential to evaluate the effectiveness of the drying method and assess product quality.

09/04/2025

We had arranged for a batch of tomatoes to conduct a drying trial. But Unfortunately, we couldn’t get a full load of tomatoes trial had to be cancelled. We plan to reschedule it for when tomatoes are available for full load.

11/04/2025

We brought 145 kg of tomatoes from the market, out of which 120 kg were fully loaded onto the solar dome dryer. From this batch, 25 kg of wastewater was removed. The tomatoes were then spread on trays of 3 kg per tray. A data logger was attached at one on the south-facing side, one near the duct, and another on the outer fan. The dome was then covered with an HDPE sheet, and both the fan and data logger were switched on.

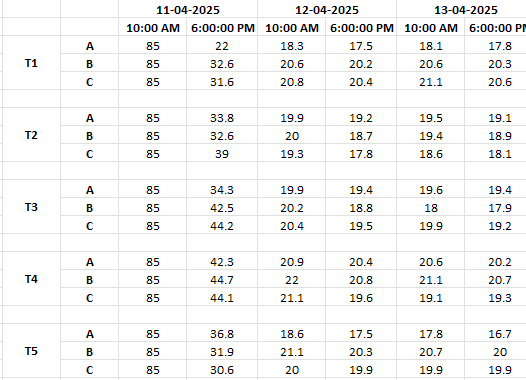

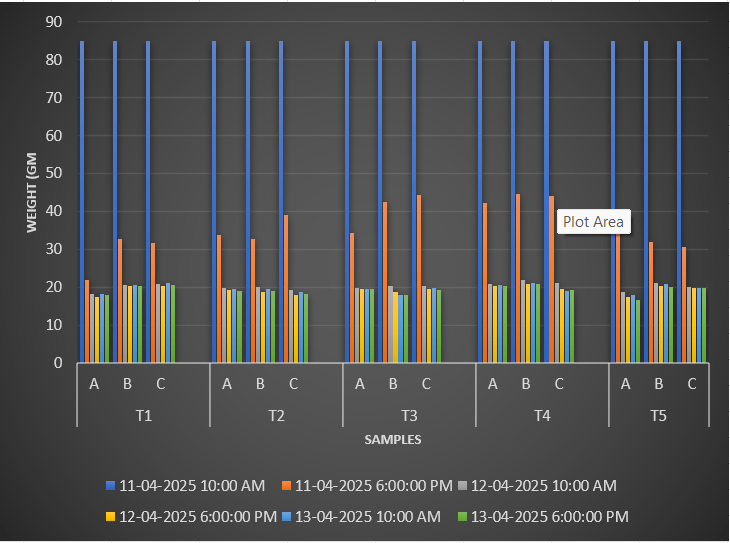

To determine the sample weight, 85 grams of tomato were placed on an area of 1 square foot.

To measure the thickness of the tomato, we used a vernier caliper. We had a slicer plate that 4mm thickness, but the tomato was cut with a thickness of 3.29mm it.

12/042025

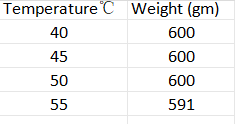

We monitored temperature and humidity data throughout the day to examine their effect on the drying process and took the Weight of the onion sample at 10:00AM and 6:00PM.

13/04/2025

We monitored temperature and humidity data throughout the day to examine their effect on the drying process and took the Weight of the onion sample at 10:00AM and 6:00PM.

14/04/2025

We removed the dried tomatoes from the solar dome dryer and also took readings at 10:00AM.

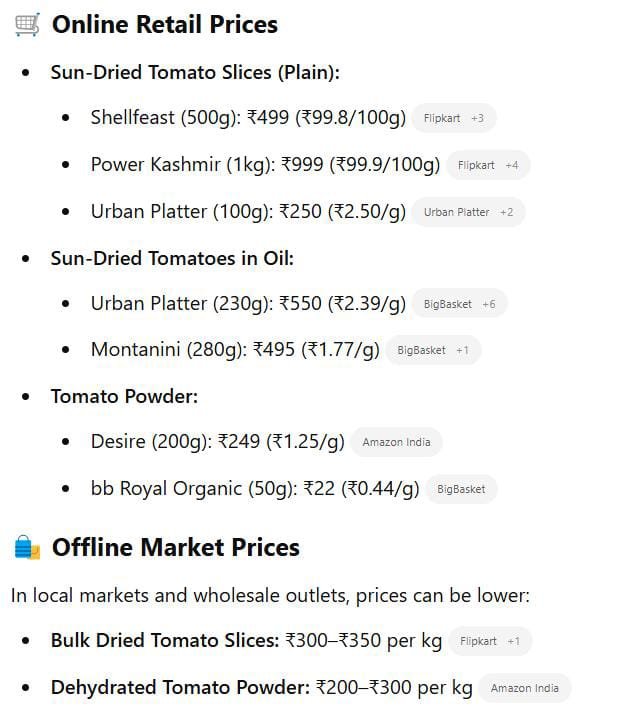

Once the tomatoes have been removed, carefully record the weight of each individual structure involved in the drying process. Use these measurements to accurately calculate the weight of the tomatoes.

We had placed this sample for testing on a mesh measuring 20 cm by 20 cm to evaluate its performance under the given conditions.

-Total loading = 120kg

-Loading per tray = 3kg

-Sample size = 85gm

-Final weight = 6732gm

These are the readings collected over 3 days

Conclusion:

–A total of 120 kg of fresh tomato slices were loaded into the solar dome dryer, with each tray holding 3 kg. After the drying process, the final dried weight was 6.732 kg, indicating that approximately 113.268 kg of water was removed from the tomatoes.

–The drying process took 3 days, with an average water removal rate of approximately 28.32 kg/day.

–The tomatoes were removed from the dryer at a final moisture content of 10–15%, suitable for long-term storage and quality preservation.

–This trial confirms the high efficiency of the solar dome dryer in significantly reducing moisture content while maintaining product quality. The system proves to be a viable and sustainable method for large-scale tomato drying and post-harvest management.

15/04/2025

Prasad sir Abhijeet sir informed us that we needed to conduct trials using the Agro Rangers and the solar dome dryer. For this purpose, we required 150 kg of onions. So, we went to a farmer in the village to buy the onions. After meeting the farmer, we purchased 150 kg of onions. Then, to prepare for the solar dome dryer trial, we cleaned the dryer thoroughly. We also checked the data loggers and the fan to make sure they were working properly and performed the necessary maintenance on them.

After completing the cleaning and maintenance of the solar dome, the members from Vigyan Ashram extended their support by assisting us with the cleaning, sorting, and peeling of onions.

16/04/2025

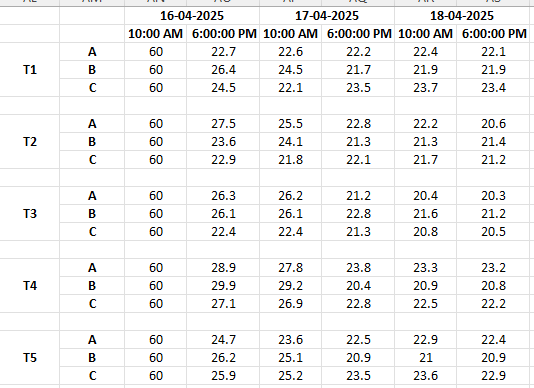

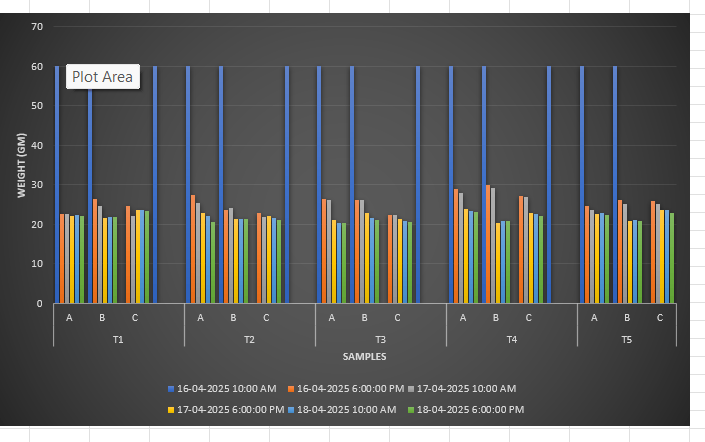

We started getting ready for the drying trials by collecting the trays from the slicer machine and the weighing scale. Then, we sliced the onions and spread them evenly on the trays of the solar dome dryer. Each tray was loaded with 2.5 kilograms of sliced onions, and we filled up the whole dryer. Mahesh Sir, Abhijeet Sir, and our teammates Shivanjali, Satyam, Aditya, and Chadvik, sayali all helped us set up and organize the entire process.

The solar dome dryer was completely loaded with produce and properly prepared to begin the drying process.

After completing the onion loading process in the solar dome dryer, we visited Agro Rangers to initiate a new drying trial. During our visit, Sagar Sir provided us with detailed insights into their advanced drying system.

He explained that the dryer used at Agro Rangers is electrically powered, but it also integrates a solar collector, which enhances energy efficiency by utilizing solar energy for heating. The system is equipped with multiple features, including:

-Humidity control for maintaining optimal drying conditions,

-Ambient and cabinet temperature monitoring to ensure consistent drying,

-Electric heaters and blowers for controlled hot air circulation,

-And 3 kW infrared (IR) bulbs that provide uniform and efficient heating.

Humidity was 16.2, cabinet temperature was 43.3, and ambient temperature was 38. Then he told us that they usually keep the cabinet temperature 5–6 degrees Celsius higher than the ambient temperature.

The total drying capacity of the electric dryer is 30 kg. Sagar Sir also guided us on how to properly set up, operate, and manage each component to ensure effective and consistent drying results.

After understanding all the information, we initiated the drying trial using an electric dryer. A total of 30 kg of onions were prepared for drying. The dryer consisted of 12 trays, and we evenly spared the load by placing 2.5 kg of onions on each tray. This ensured uniform drying across all trays. Once the onions were loaded, the electric dryer was set up and the trial commenced under controlled conditions.

17/04/2025

The next day, we checked the condition of the onions and, seeing that the onions had dried, we took them out of the dryer.

-Initial weight = 30kg

-Per tray = 2.5kg

-Final weight = 4,4kg

-Total hrs = 7hrs

And also took the readings of solar dome dryer.

18/04/2024

We monitored temperature and humidity data throughout the day to examine their effect on the drying process and took the Weight of the onion sample at 10:00AM and 6:00PM.

19/04/2025

After discussion with Dixit Sir, Prasad Sir, and Abhijeet Sir about the drying process, we took the onions out of the first dryer to check them. We found that the onions still had about 23% moisture, which is more than what is needed for safe storage or use. So, to dry them more and remove the extra moisture, we put the onions into the electric dryer.

Onion weight 13,630kg

20/04/2025

We took the onions out of the electric dryer. When we placed them in the solar dome dryer, their weight was 13.630 kg.

The weight when they were taken out of the electric dryer was 12.980 kg.

-Initial weight = 100kg

-Loading per tray = 2.5kg *40 =100kg

-Sample size = 60gm

-Final weight = 12,980kg

Conclusion:

A total of 100 kg of fresh onion slices were loaded into the solar dome dryer, with each tray holding 2.5 kg. After the drying process, the final dried weight was 12.98 kg, indicating that approximately 87.02 kg of water was removed from the onions during drying.

The drying process took 3 days, with an average water removal rate of approximately 29.01 kg/day.

The onions were removed from the dryer at a final moisture content suitable for long-term storage and quality preservation, ensuring minimal degradation in texture, color, and flavor.