INTRODUCTION:

Dehydration is a method of food preservation that removes moisture from vegetables like tomatoes and onions, extending their shelf life and reducing weight for easier storage and transport. The process involves drying the vegetables using methods such as sun drying, air drying, or mechanical drying (e.g., hot air, freeze drying).

Tomato Dehydration: Tomatoes are sliced or pureed and dried at moderate temperatures (50–70°C) to retain color and flavor. Common products include dried tomato slices, powders, and flakes.Onion Dehydration: Onions are peeled, sliced, and dried at around 50–60°C. The final product includes onion flakes, granules, or powder, commonly used in seasonings and processed foods.Dehydration helps preserve the natural taste and nutrients while preventing microbial growth.

Solar dryer

Solar dryers are devices that use solar energy to remove moisture from food products. They are more efficient than traditional sun drying as they protect food from dust, insects, and contamination.

The main types of solar dryers include:

1. Direct Solar Dryer:Food is exposed to sunlight inside an enclosed chamber with a transparent cover.Heat builds up inside, accelerating the drying process.Example: Box-type solar dryer.

2. Indirect Solar Dryer:Sunlight heats the air in a separate solar collector, and the warm air is circulated into the drying chamber.Prevents direct exposure to sunlight, preserving color and nutrients.Example: Cabinet solar dryer.

3. Mixed-Mode Solar Dryer:Combines direct and indirect drying.Sunlight heats both the drying chamber and the air, increasing efficiency.

4. Hybrid Solar Dryer:Uses solar energy along with an auxiliary heat source (electric or biomass) for drying even when sunlight is low.Suitable for commercial drying operations.

Each type is chosen based on climate conditions, the type of product, and the drying efficiency required.

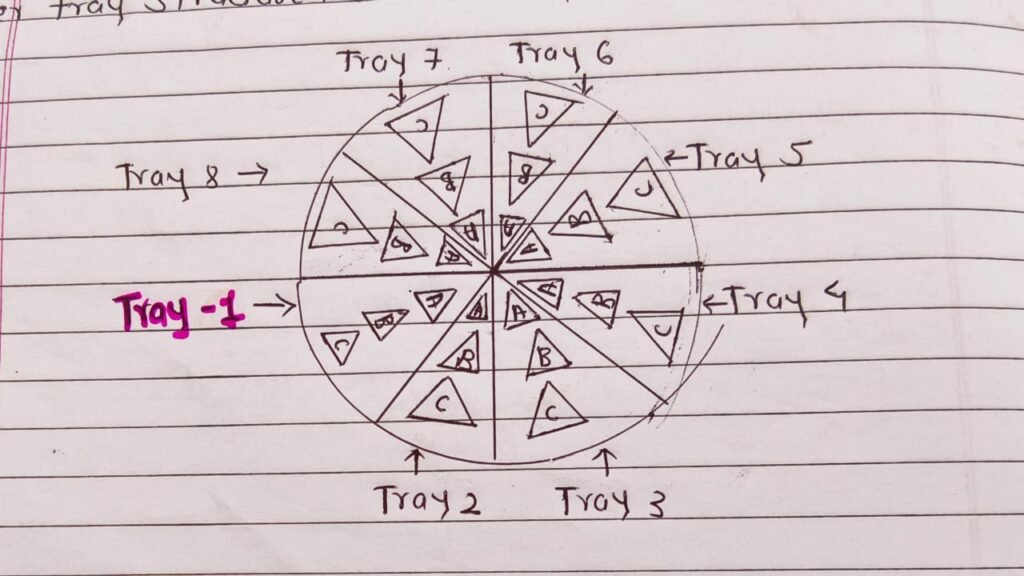

Dome Solar Dryer

A Dome Solar Dryer is a type of solar drying system designed with a dome-shaped structure that efficiently traps solar heat, providing uniform drying conditions for various agricultural products like fruits, vegetables, spices, and herbs.

Features & Working Principle Dome-Shaped Structure: Maximizes sunlight absorption and enhances airflow. Transparent Cover: Usually made of polycarbonate or UV-stabilized plastic, allowing sunlight to penetrate while preventing heat loss. Ventilation System: Ensures proper air circulation to remove moisture efficiently. Solar Energy Utilization: Uses direct solar radiation to heat the air inside the dome, accelerating the drying process.

01/03/2025

On the first day, I received an overview of the industry from dixit sir .They provided insights into the daily operations, processes, and activities that take place within the industry. Understanding the workflow helped me get a clear picture of my responsibilities during the attachment.

02/03/2025

Learning About Dryers & Flat-Bed Dryer Modification

I gathered information about different types of dryers and their applications. One key task was disassembling a flat-bed dryer to replace its plywood with a polycarbonate sheet. This change aimed to improve durability and efficiency, as polycarbonate is more resistant to moisture and heat.

03/03/2025

Discussion on Product Drying Feasibility

I had a discussion with Dixit Sir regarding the types of products that could be dried using the available dryers. We explored the pre-processing required for different materials and the feasibility of drying various agricultural products.

04/03/2025

Cleaning Solar Dome Dryer Trays

Before starting trials, I cleaned and washed the trays of the solar dome dryer to maintain hygiene and prevent contamination during the drying process.

05/03/2025

Industry Visit to AGRO Ranger Grading Startup

Visiting the AGRO Ranger Grading startup provided insights into their grading and drying processes. Observing their techniques helped me understand different approaches to handling agricultural produce efficiently.

06/03/2025

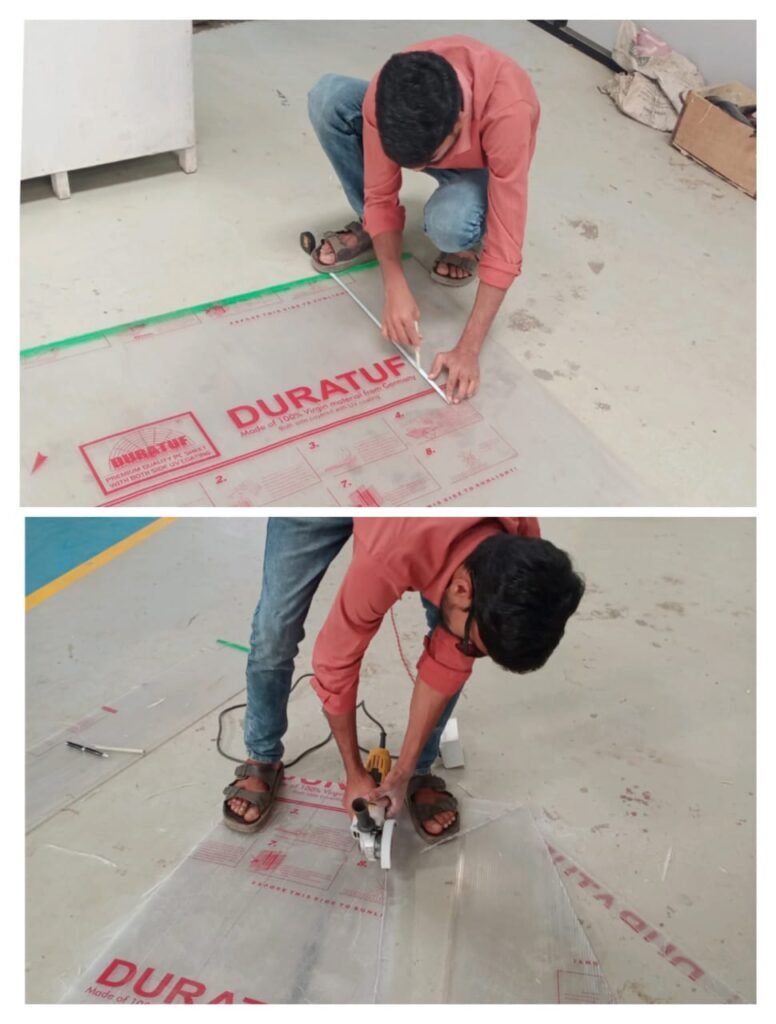

Preparing Polycarbonate Sheets for Flat-Bed Dryer

I measured and cut the polycarbonate sheets to fit the flat-bed dryer, ensuring proper installation for enhanced performance.

07/03/2025

Attaching Polycarbonate Sheets to the Flat-Bed Dryer

After preparing the sheets, I attached them to the dryer structure, replacing the old plywood material. This modification improved the dryer’s lifespan and efficiency.

08/03/2025

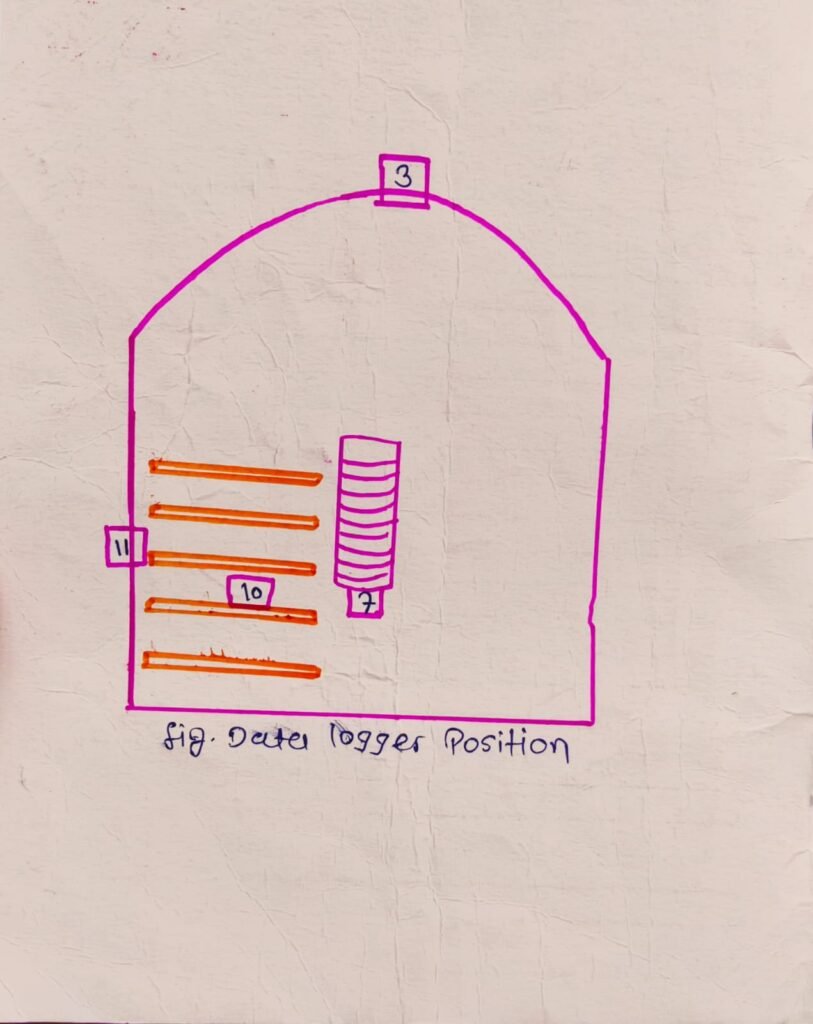

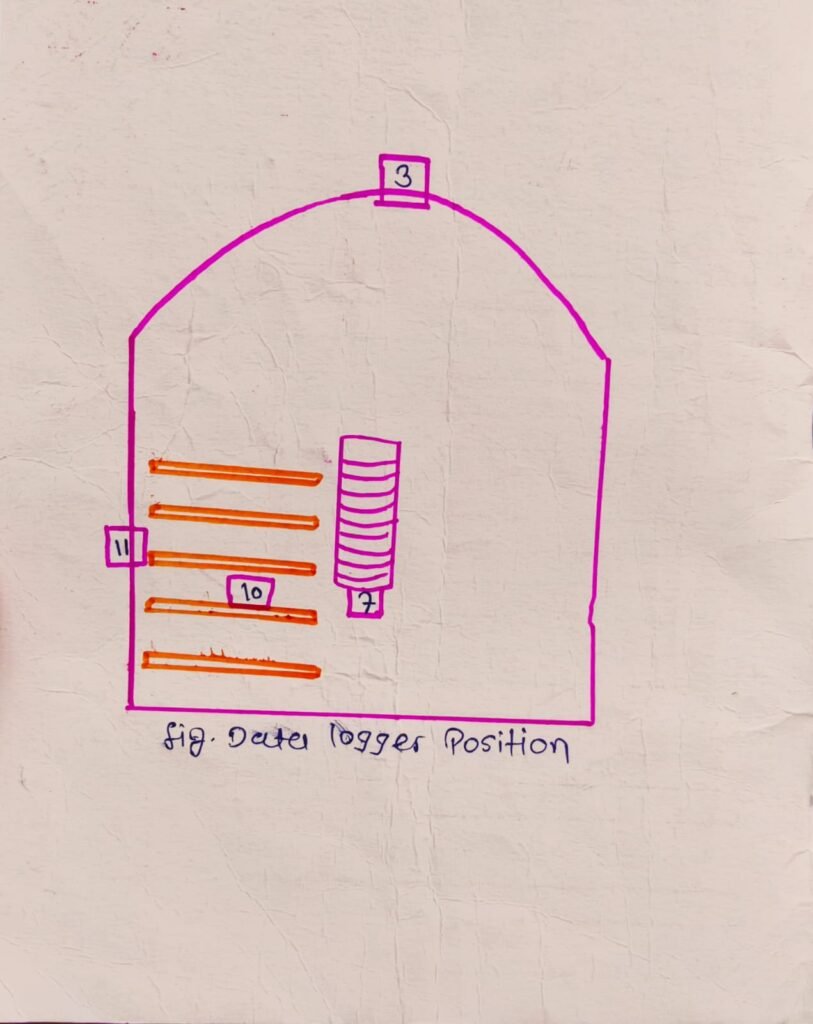

Installing a Data Logger in the Polyhouse

A visit to a nearby polyhouse allowed me to install a data logger, which helps in monitoring environmental parameters such as temperature and humidity.

12/03/2025

Painting and Positioning the Flat-Bed Dryer

I painted the flat-bed dryer to protect it from rust and environmental wear and then placed it on the terrace for testing.

13/03/2025

Purchasing Mesh for Solar Dome Dryer Trays

To enhance airflow and drying efficiency, I purchased mesh for the solar dome dryer trays. This addition helps maintain even drying and prevents product contamination.

14/03/2025

Mesh cutting of solar dome dryer.

15/03/2025

Fixing the Mesh on Solar Dome Dryer Trays

After purchasing the mesh, I attached it to the trays, ensuring proper airflow for uniform drying of products.

16/03/2025

Measuring Tomato Requirement for Drying

To understand space utilization, I purchased tomatoes and measured how many tomatoes fit per square foot of tray space.

17/03/2025

Preparing Steel Strips for Fan Installation

I acquired steel flat strips, cut them to the required size, and bent them to fit the dryer’s fan installation system. This was essential for enhancing air circulation within the dryer.

18/03/2025

Celebrating Cultural Day

Participating in Cultural Day at the institute was a refreshing break. It provided an opportunity to interact with colleagues and understand workplace culture.

19/03/2025

Setting Up Air Circulation System & Purchasing Tomatoes

I worked on setting up an air circulation system in the solar dome dryer to improve drying efficiency. Additionally, I purchased tomatoes for conducting drying trials.

20/03/2025

Tomato Drying Procedure

- Selection & Sorting

Choose ripe, healthy tomatoes

Remove damaged or spoiled ones

- Washing & Cleaning

Wash thoroughly with clean water

Remove dirt and pesticide residues

- Cutting & Slicing

Slice tomatoes into uniform pieces (e.g., halves or thin slices)

Remove seeds if necessary

- Pretreatment (Optional)

Dip in citric acid or blanching for color retention and microbial control

- Drying Method Selection

Sun Drying → Spread on trays under direct sunlight

Solar Drying → Use a solar dryer for better efficiency

Oven Drying → Dry at 50-60°C in an oven

Dehydrator Drying → Use a food dehydrator at 50-60°C

- Monitoring & Turning

Turn slices regularly for even drying

Ensure proper air circulation

- Final Drying Stage

Continue drying until moisture content is 10-15%

Texture should be leathery and flexible

- Cooling

Allow dried tomatoes to cool before packaging

- Packaging & Storage

Store in airtight containers or vacuum-sealed bags

Keep in a cool, dry place away from sunlight

Preparing & Placing Tomato Slices for Drying

I sliced the tomatoes and arranged them on trays in the solar dome dryer. A data logger was installed to record temperature and humidity changes during the drying process.

21/03/2025

Recording & Analyzing Temperature and Humidity

Throughout the day, I monitored and recorded temperature and humidity readings. This data helped analyze drying efficiency and environmental impact

.https://1drv.ms/x/c/a37be4bd92fb27ac/EVcoYRe2ictKgh2qJtO75w8B2KMjs5DLQaL6qucOsJ7Qzg?e=YjPD3F

22/03/2025

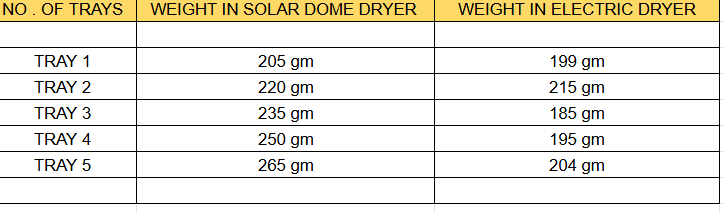

Transferring Tomatoes to Flat-Bed Dryer

To compare drying methods, I transferred the partially dried tomatoes from the solar dome dryer to the flat-bed dryer for further experimentation.

23/03/2025

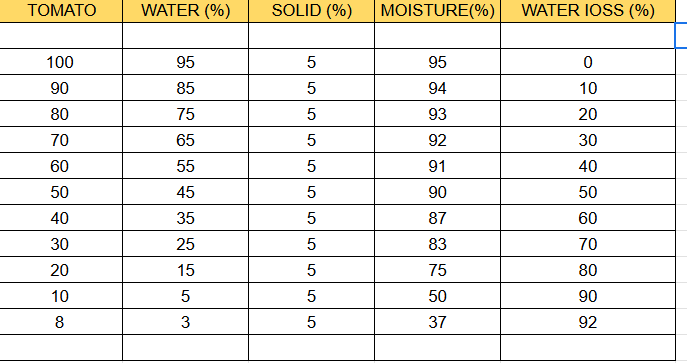

We discussed with Dixit sir and Prasad sir and they interpreted following data .

Using an Electric Dryer for Final Moisture Removal

Once the tomatoes had dried significantly, I placed them in an electric dryer to remove any remaining moisture, ensuring optimal storage quality.

Final dried tomatoes.

Total initial weight of tomato = 60 kg

total loaded weight of tomato = 48 kg

total dried weight after removed from solar dome dryer = 3.828 kg

Total dried weight after removed from electric dryer = 3.299 kg .

24/03/2025

Cleaning the Solar Dome Dryer & Planning Onion Drying

After completing the tomato trial, I cleaned the solar dome dryer and discussed the next trial, which involved drying onions.

25/03/2025

Purchasing & Preparing Onions for Drying

Process followed:

Raw Onion Selection

↓

Cleaning & Peeling

↓

Slicing/Chopping

↓

Blanching (Optional)

↓

Pre-Drying Treatment (if needed)

↓

Drying Process

│

├── Hot Air Drying

├── Freeze Drying

├── Sun Drying

└── Vacuum Drying

↓

Cooling

↓

Grinding (if powder is needed)

↓

Sieving & Grading

↓

Packaging

↓

Storage & Distribution

I purchased onions and removed their outer skin in preparation for slicing and drying.

26/03/2025

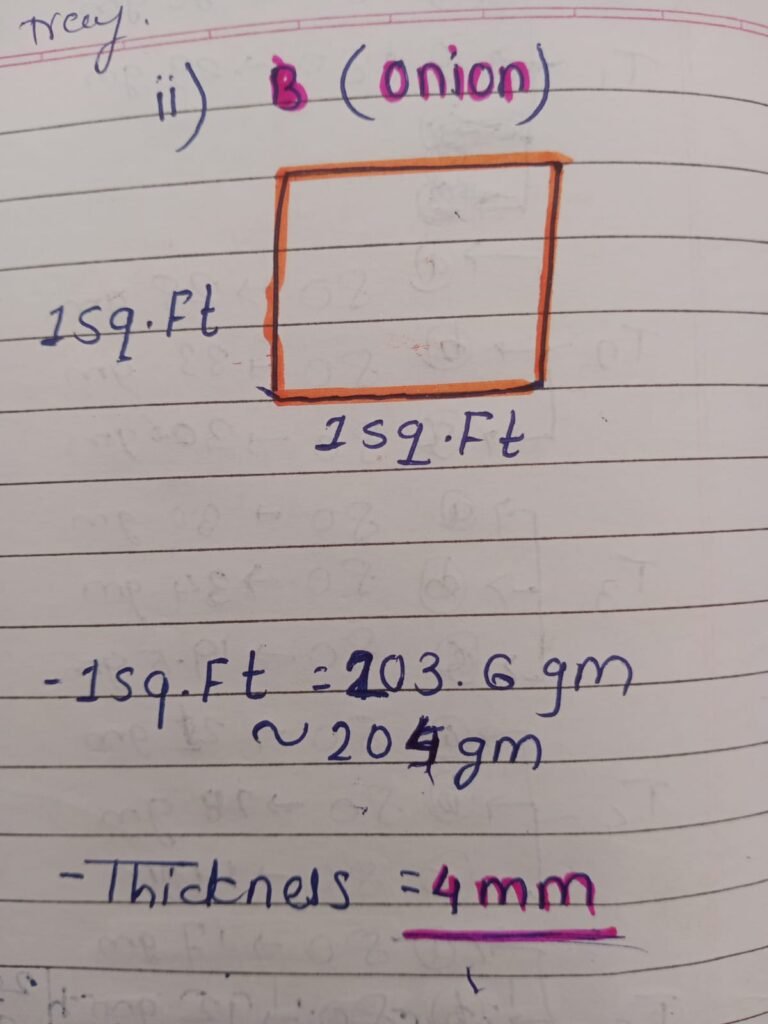

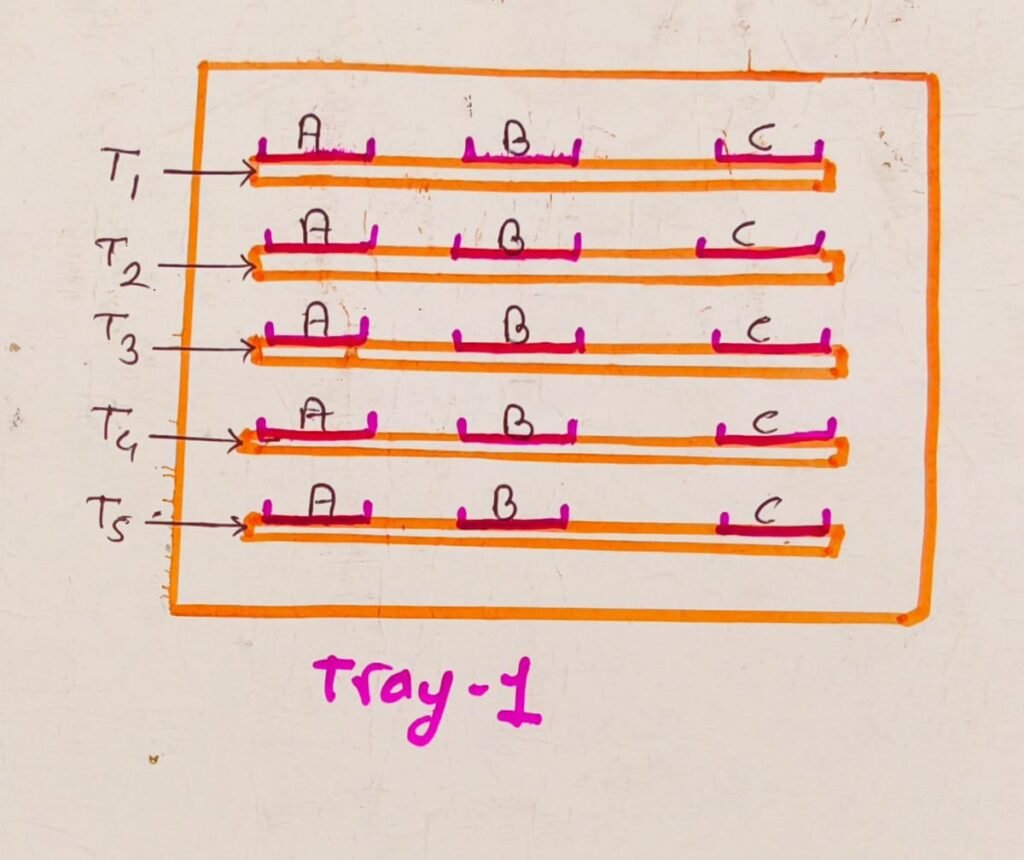

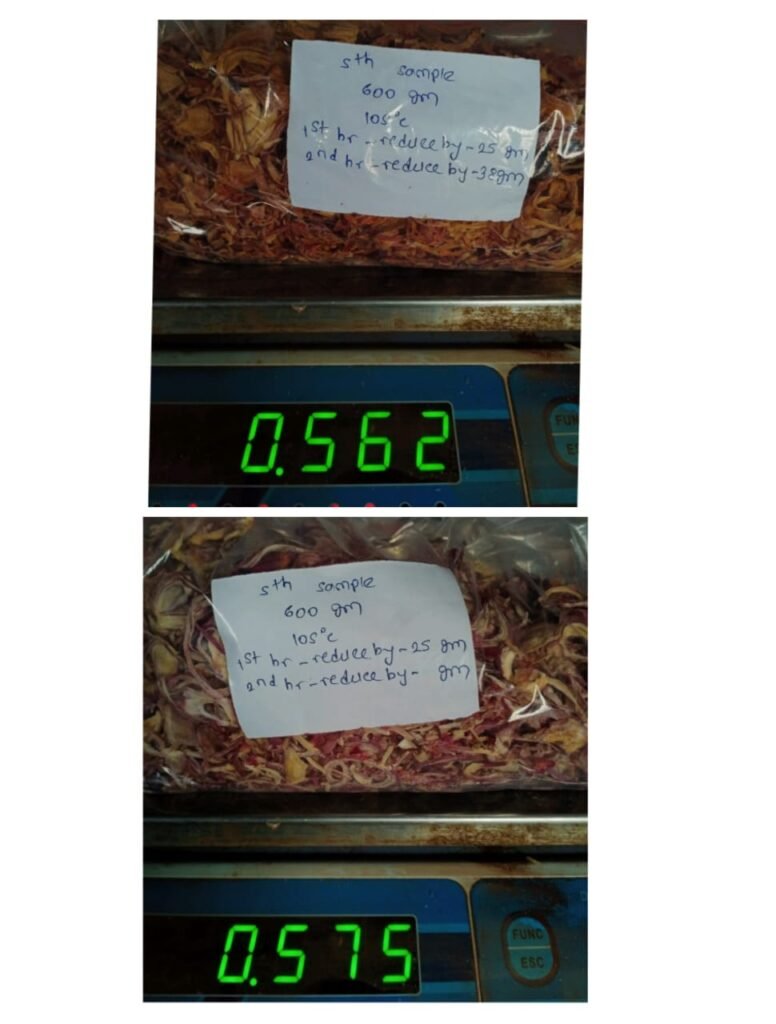

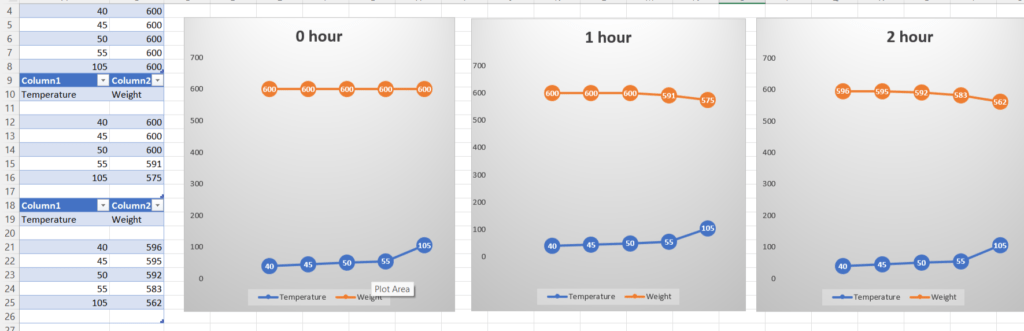

Preparing Sample Meshes for Monitoring Drying

To monitor the drying process effectively, I cut 15 meshes of 20 sq. cm each for sample placement in different trays.

Surface area of one tray= 13 sq. ft.

Therefore, 13*204=2652

So we take 2500 gm for 13 sq. ft.

Therefore, for 15 trays we use 37.5 kg onions.

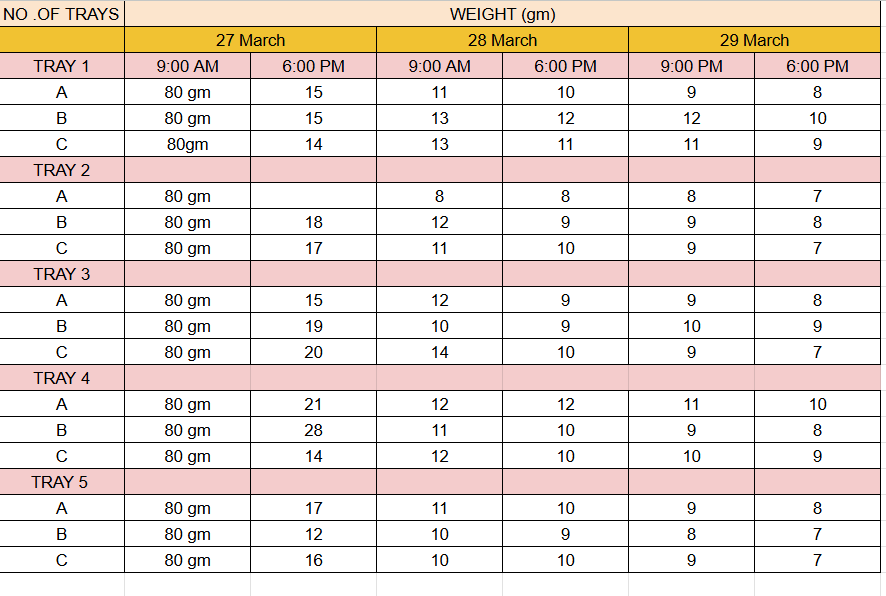

27/03/2025

Slicing Onions & Placing Them in the Dryer

Using an onion slicer, I cut the onions into uniform pieces and placed them on trays in the solar dryer for the next phase of trials.

Total initial weight of onions =44 kg

Total loading=37.5 kg

29/03/2025

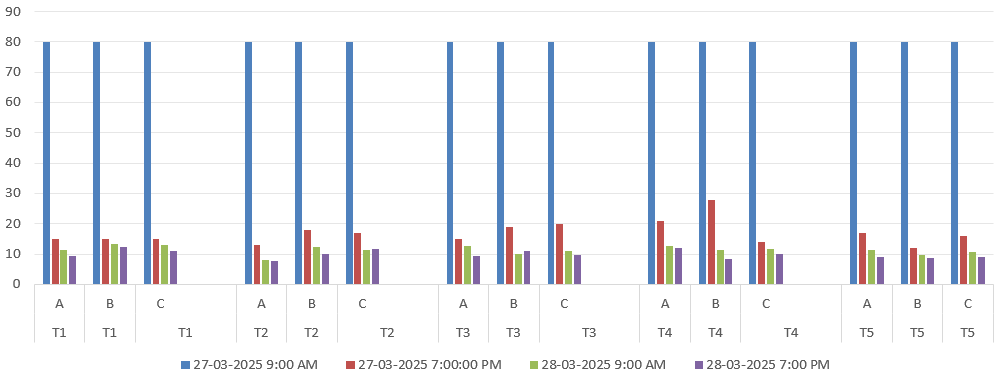

Monitoring & Analyzing Temperature and Humidity Data

I recorded temperature and humidity levels throughout the day and analyzed how they affected the drying process.

30/03/2025

Discussing Onion Drying Results with Mentors

After drying the onions, I consulted with my mentors to discuss the results and determine whether any process adjustments were needed.

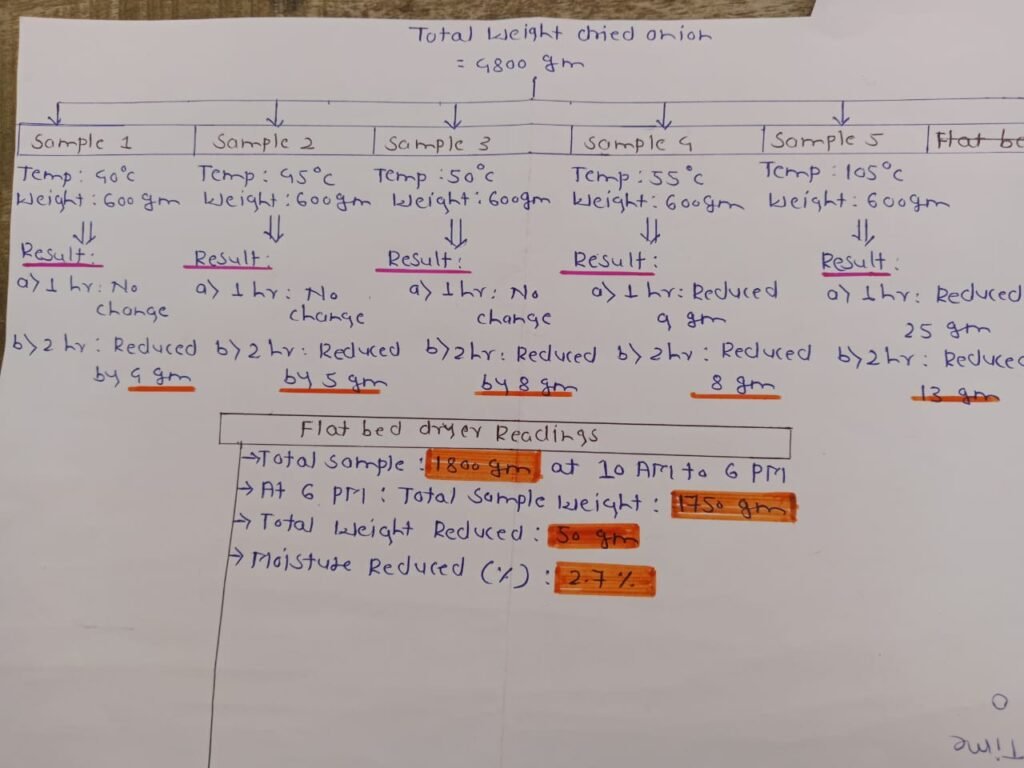

Further Drying Onions in Electric & Flat-Bed Dryers

To compare different drying techniques, I placed some of the dried onions in an electric dryer and others in a flat-bed dryer for additional trials.

31/03/2025

Analyzing Onion Drying Time & Temperature Requirements

I conducted an analysis to determine the optimal time and temperature for drying onions, ensuring maximum efficiency and quality.

Writing a Report on Industrial Attachment

Finally, I compiled all my findings, observations, and learnings into a comprehensive report on my industrial attachment experience.

Conclusion:

This day industrial attachment was an enriching experience. It provided hands-on exposure to various drying technologies, product trials, and data analysis techniques. I gained practical skills, problem-solving abilities, and a deeper understanding of industry operations. The knowledge I acquired during this period will undoubtedly help me in my future endeavors within the food processing and drying industry.