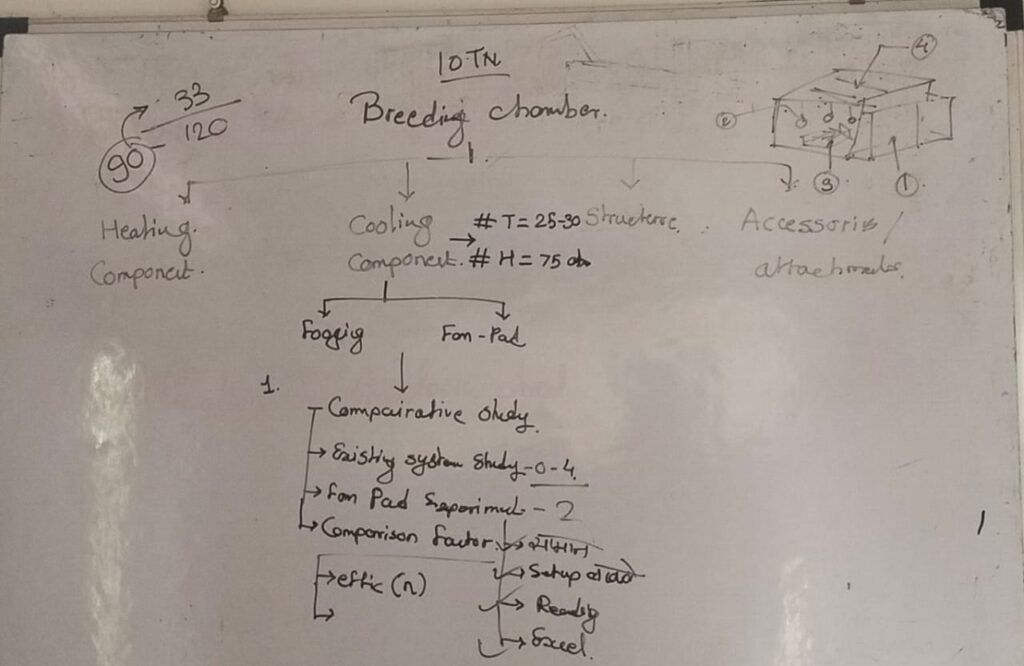

INTRODUCTION

This was my first main project that was given to me by Vigyan Ashram.

I got the project of bsf breeding chamber. So I collected some basic information related to bsf so that I can know about the project

WHAT ARE BLACK SOLDIER FLIES (BSF)?

The ‘Hermetia illucens’, also known as black soldier fly (BSF) are long black coloured flies. These flies have a huge appetite at the larval stage, therefore used as decomposers of organic substrates to recycle manure, especially livestock waste; generate oil and protein rich feed for farm/pet animals and fish. Companies like AgriProtein, InnovaFeed and Protix produce them in their insect factories. They are harvested in grub composters. They are known to reduce organic chemical pollutants. Their excreta known as frass can be used as organic fertiliser directly.Research has also been carried out for purification of biomass with heavy metals.

PROPERTIES AND LIFE- CYCLE

They are about 16mm long, black in colour and have metallic appearance (blue/green on thorax and red on the abdomen). It is a mimi fly, resembling the ‘organ pipe mud dauber’. Mating can occur after 2 days of being an adult. In order for the mating to occur the males require good lekking sites where they display their dominance. An adult female lays 206-639 eggs at a time, in small spaces or surfaces of decaying matter. The eggs take 4 days to hatch. The larvae are 1mm initially and can go upto 25mm and 0.1-0.22g and complete development in about 14 days. Being an insatiable feeder the larvae are known to decompose material quickly during this period in cool dark places. The larva finds dry sheltered places to initiate pupation which lasts for 1-2 weeks. The adults live for 47-73 day with food (nectar) and 8-10 day with water and stored fats.

NEED FOR THE PROJECT

BSF project is to develop waste management system for wet biodegradable waste.

BSF needs Optimum Temperature (25-30°C) & humidity (above 70%) for laying eggs. The project is to maintain required Temperature & humidity.

Objective

To design methods either a fan pad system or foggers system

To maintain Temperature (25-30°C) and humidity below 75%

fabricate

Test this system

To look at the advantages and disadvantages of fogger system and fan pad system with respective 1) running cost 2) capital cost 3) Easy of operation and energy consumption.

14/9/24

Today we had a discussion with Kulkarni sir about the project allotted . Mahesh sir asked me to find out which cooling method is better between fanpad system and fogger system for BSF chamber.

15/9/24

Today I had a discussion on my project with Dixit sir, and helped Shrutika Didi in filling the bottle of H2S water distillation kit.

16/9/24

0ur HOD Dr. Sandeep Jain, Department Of Farm Structures, College Of Agriculture Engineering visited Vigyan Ashram, we explained our project work , and sir gave us suggestions . Today I helped Tejaswini Didi to take readings of temperature, air flow in polyhouse

17/9/2024

Today we had a discussion with Dixit Sir . In the old BSF chamber the water from the fogger system saturates on the floor causing flies to die. For this reason, it was decided to give a certain slope to the floor, so water will not accumulate on the floor.

To bring the 40 °C temperature to 25 °C and to bring the 20% humidity to 70, how much efficiency of the pad is required?

1m^3 =1.29kg=1.005 KJ/kg

Q= mCpΔT

=1.291.00515

=19.44 KJ

water Evaporation = 19.44/2.257=8.61gm

New water Content =8.61+ 13.11(10.171.29)/1.29=16.83

Efficiency= 16.83/19.96=0.84*100=84% .

84% efficiency of the pad is required

18/9/24

Dixit sir asked to calculate the efficiency of the fan pad installed in the polyhouse.

Sir asked to use 40 watt fan to get efficiency.

First of all, a 10mm thick Honeycomb structure pad was taken, after which the pad was completely soaked with water and then the pad was kept in front of fan and the readings of temperature, humidity, windspeed in front and behind the pad were taken at all three speeds of the fan. Then room temperature, humidity and wet bulb temperature were taken

20/9/24

outside Temperature = 28.8 °C

Room Humidity = 61.4%

wet bulb Temperature = 23.14°C

pad Thickness= 10cm

| dry-bulb temp. of leaving air from pad | humidity | wind speed (pad front side) | wind speed ( pad back side ) | |

| 1 | 23.5 | 86.3 | 1.1 | 4.0 |

| 2 | 23.4 | 87.6 | 0.9 | 3.4 |

| 3 | 23.3 | 88.9 | 0.8 | 3.2 |

η= t db (1) – t db (2) / t db (1) – t wb (1) * 100

η= cooling efficiency(%)

t db (1) = the outside dry-bulb temperature of entering air to pad (°C)

t db (2) = the dry-bulb temperature of leaving air from pad (°C)

t wb (1) = the outside wet-bulb temperature of entering air to pad

η = 28.8-23.3 / 28.8-23.14 * 100

η = 97%

21/9/24

The efficiency of the pad was 97%. After showing the calculations to Dixit sir, sir asked to cut the round pad again and take the readings again.

Then again I cut the pad in circle and again took readings of temperature humidity and windspeed at all three speeds of the fan. After that, room temperature, humidity and wet bulb temperature were calculated

room temp= 30.6 °C

humidity= 60.5%

wet bulb temp= 24.62 °C

pad thickness= 10cm

| temperature | humidity | wind speed ( front side ) | |

| 1 | 26.5 | 76.5 | 0.5 |

| 2 | 26 | 82 | 0.4 |

| 3 | 25.9 | 83.9 | 0.4 |

η= t db (1) – t db (2) / t db (1) – t wb (1) * 100

η= cooling efficiency(%)

t db (1) = the outside dry-bulb temperature of entering air to pad (°C)

t db (2) = the dry-bulb temperature of leaving air from pad (°C)

t wb (1) = the outside wet-bulb temperature of entering air to pad

η= 30.6-25.9 / 30.6 – 24.62 * 100

η = 4.7 / 5.98 * 100

η = 96 %

23/9/24

I had a discussion with Prasad sir and in that discussion sir helped me to remove the map of the project that I got

24/9/24

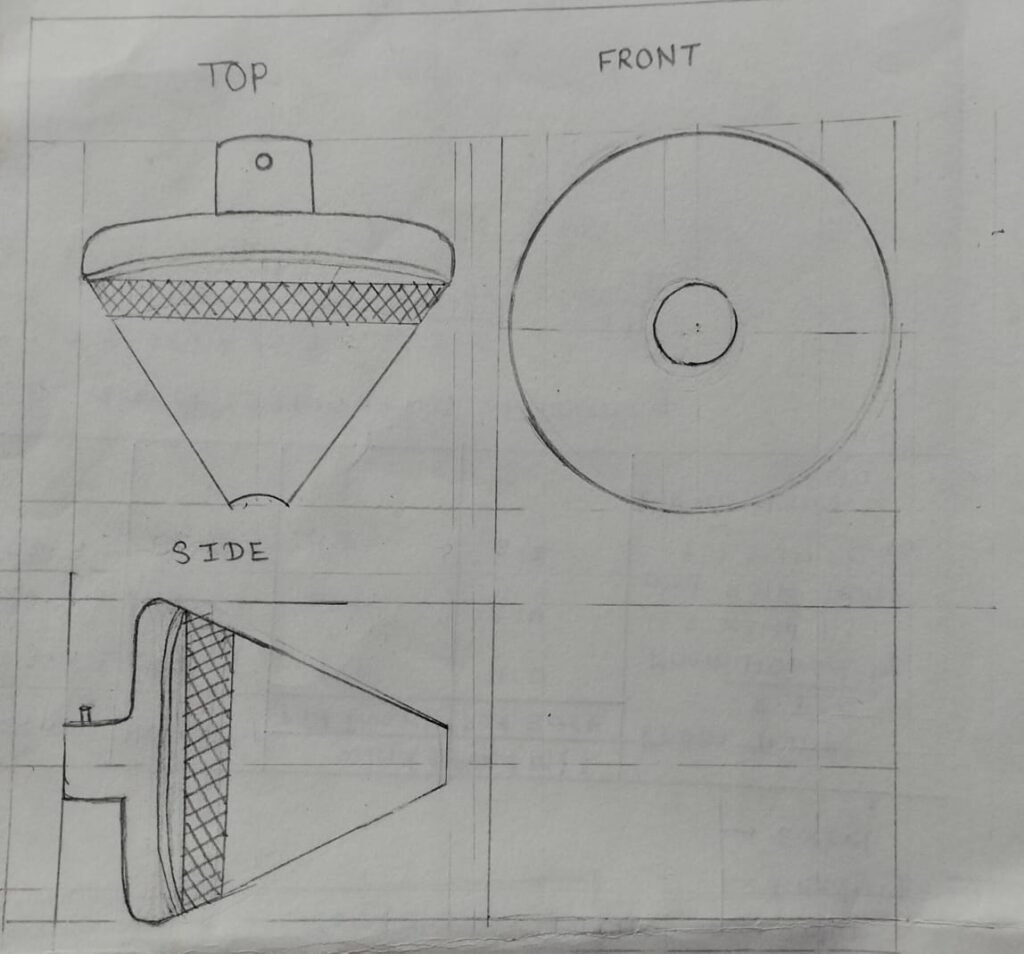

Prasad sir said that efficiency of pad can be calculated in different ways.

After that, the raw design of the cone was taken and then it was drawn on solid works.

Take one diameter of the cone equal to the diameter of the fan and take another diameter of the cone equal to the diameter of the anemometer fan and draw the drawing

25/9/24

Designed the cone on solid works and then cut the cone

27/9/24

A pad of 10mm was taken and it was cut into a circle equal to the diameter of the fan and after soaking it in water, the fan was placed in front and the upper part was wrapped with aluminum foil.

Then readings of temperature, humidity and windspeed were taken. And again the efficiency of the pad was calculated

The readings are as follows:

room temp: 26.4

humidity= 80.63%

wet bulb temp= 23.86

pad thickness=10cm

| temerature | humidity | wind speed ( pad front side)m/s | wind speed ( pad back side ) m/s | |

| 1 | 24 | 85.4 | 3.5 | 4.5 |

| 2 | 24.4 | 83.5 | 2.9 | 3.8 |

| 3 | 24.9 | 82.5 | 2.6 | 3.4 |

η= t db (1) – t db (2) / t db (1) – t wb (1) * 100

η= cooling efficiency(%)

t db (1) = the outside dry-bulb temperature of entering air to pad (°C)

t db (2) = the dry-bulb temperature of leaving air from pad (°C)

t wb (1) = the outside wet-bulb temperature of entering air to pad

η = 26.4 – 24 / 26.4 – 23.86 * 100

η = 94 %

5/10/24

had a discussion with dixit sir, he explained an example,

- 1000ml water = 50°C

1000ml water = 30°C.

therefore (2000ml water) =50*1000+30*1000÷2000

=50+30%2= 40°C. - 5000ml water= 30°C 1000m1 water=50°C therefore 50*1000+ 30*5000/6000=33.3°C. The room air is 50 degree Celsius and the outside air is 42 degree Celsius, the humidity is 20% and the efficiency of the pad is 85%. If the temperature in the room is to be brought up to 30 degree Celsius, how much air must be taken out and how many cfm fan for that? Dixit sir asked to calculate what will be required

6/10/24

Consider,

Outer temperature (T1) = 40 °C.

Relative Humidity = 20%

Wet Bulb Temperature (WB) = 22 °C.

Cooling pad efficiency ( η )=85% = 0.85

Temperature through cooling pad (T)

We can get air temperature received through cooling pad by efficiency formula

η = T1-T / T1-WB

0.85= 40 – T / 40 – 22

T= 0.85 * 18-40

T=24.7 °C

It is found that 24.7°C is the intake air temperature received when 40°C temperature of air is passed through 85% efficient evaporative cooling pad.

temperature inside (T1)= 40°C.

intake temperature received through evaporative cooling pad (T2)= 24.7 °C

Mass of air inside (m1) = 1m3/min

mass of air to be exhausted out (m2) = ?

RT= (m1 * T1) + ( m2 * T2) / m1+ m2

28 = (1 * 40) + ( m2* 24.7) / 1+ m2

28+28m2 = 40 + 24.7 m2

28 m2 – 24.7 m2 = 40-28

3.3m2 = 12

m2 = 3.63 m^3 / min

7/10/24

After the discussion with Prasad sir, he asked me to take the readings of the fan with higher and lower cfm than the cfm of the fan used to calculate the efficiency of the pad, then I took the readings of the blower with higher cfm.

8/10/24

Room temperature= 28.1°C

Humidity= 70%

wet-bulb temperature= 23.8°C

| Blower wind speed m/s ( 6340 cfm) | Temperature | Humidity |

| 4.6m/s | 24.3°C | 87% |

9/10/24

After that again I took readings of 100 cfm fan

Room Temperature= 31°C

humidity =59%

wet bulb temperature= 24.726°C

| fan wind speed (100cfm) | Temperature | Humidity |

| 1.8 m/s | 25.2°C | 78.9% |

13/10/24

After showing calculation to Prasad sir he asked me to measure the cfm of fan and blower then I measured the cfm by concentrating the air with the help of anemoneter.

1st fan – 1300 cfm

2nd fan – 100 cfm

blower – 6340 cfm

| CFM | Efficiency | |

| 1st Fan | 1300 | 94 |

| 2nd Fan | 100 | 91% |

| Blower | 6340 | 88% |

18/10/24

Had a discussion with dixit sir.

19/10/24

As decided in the discussion, i checked the efficiency of the pad again today, First in took a 100 cfm fan and tied it to the window with a thread, and covered the rest of the window with aluminium foil. after that, readings of temperature, Humidity and windspeed were taken by placing a honeycomb structure pad in front of the fan. the readings taken are as follows:

| fan wind speed | temperature | Humidity |

| 1.6 m/s | 24.6°C | 89.6% |

Outesie Temperature: 31°C

humidity : 62%

efficiency = 31-24.6/31-23.417 = 6.4/7.583 = 0.84 * 100= 84%

21/10/2024

Had a discussion with dixit sir related to Fan pad System.

22/10/2024

Had a discussion with dixit sir, related to temperature and humidity control inside the BSF breeding chamber

26/10/2024

Mahesh sir asked me to draw a sketch of BSF breeding chamber.

11/12/24

I showed the design of BSF to dixit sir, he asked me to change the positions of the fan and also to change the design of the cage.

12/12/2024

After that I changed the fan position randomly.