Objective :

To prepare silver sulfate from silver for COD analysis of water samples.

Introduction :

Silver sulfate is an inorganic compound with the formula Ag2SO4. It is a white solid with low solubility in water. Chemical oxygen demand (COD) uses silver sulfate in concentrated sulfuric acid to help oxidize carbon during chemical reactions. A 25-gram of silver sulfate costs approximately Rs 7000. So we decided to make silver sulfate in the laboratory.

Cost calculation:

25 gm silver sulfate = Rs 7000

Silver 10 gm = RS. 700

for making 7.5 gm of silver sulfate we need almost 5 gm of silver and it cost around 350 rupees.

1 gloves etc.

Chemicals : Nitric Acid , Silver , Sulphuric Acid etc.

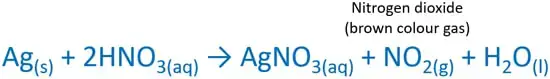

Reaction :

Silver and hot concentrated nitric acid

Silver metal reacts with hot concentrated nitric acid and produce silver nitrate (AgNO3) salt, nitrogen dioxide (NO2) gas and water as products.

Equation of reaction of Ag and hot concentrated HNO3

Ag + HNO3 → AgNO3 + NO2 + H2O

Observed brown-colored nitrogen dioxide gas is emitted during the reaction of Ag and HNO3.

Silver is a soft, white, lustrous transition metal. Produced silver nitrate aqueous solution is colourless.

Balanced equation of Ag and hot concentrated HNO3 acid reaction

0.83 g/100 mL (25 °C ) = solibility of silver sulfate in water

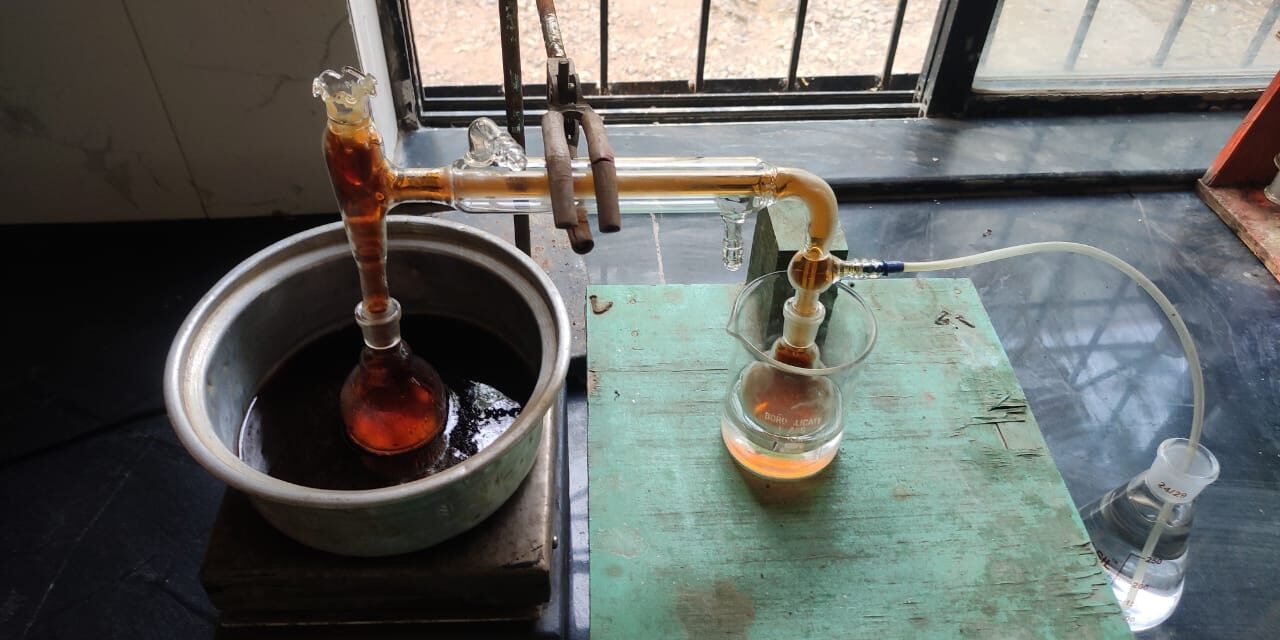

Procedure :

- Prepared a setup of silver sulfate.

- Took Round Bottom flask Added 5 gm silver in it.

- As per calculations of molecular weight we added 9.275 gm of Nitric acid(60%) and kept on heating at 80 degree for 30 minutes.

- Observed the changes in Reaction.

- weighed the silver nitrate formed in the round bottom Flask.

- As per calculations of molecular weight we added 4.54 gm of concentrated Sulphuric acid and Heated for 10 minutes.

- Weighed the Silver sulfate formed in the Round bottom flask.

Observations :

- Orange Coloured NO2 gas produced during heating of siver and Silver nitrate.

- Nitric acid produce in Round bottom flask no.2 about 7 gm. ( pH =0.96).

| Molecular Weight | Added | Produced | |

| Silver | 107.8 | 5 gm | – |

| Nitric Acid | 63 | 9.725 gm | 7 gm |

| Silver Nitrate | 169.8 | – | 12.312 gm |

| Sulphuric Acid | 98.07 | 4.54 gm | – |

| Sliver Sulfate | 311.7 | – | 7.589 gm |

Standardization of silver sulfate:

Chemical Oxygen Demand of KHP (Potassium Hydrogen Pthalate ) is 500.

Determination of COD

Chemical oxygen demand is amount of dissolved oxygen that must be present in water to oxidize chemical organic materials. The initial COD of black water is needed to determine. Sample for determining COD collected from collected black water in the tank. The procedure used for it by using COD digester is as follows:

Materials for COD test

- Potassium dichromate (K2Cr2O7).

- Mercuric sulphate (HgSO4)

- Sulfuric acid (H2SO4)

- Ferrous ammonium sulphate (FAS)

- Ferron indicator

- Potassium hydrogen phosphate (KHP)

- 250 ml Erlenmeyer flask

- Reflux condenser

- COD tubes

- Measuring cylinder

- Analytical balance

- COD tube stands

- Hand gloves

Preparation of chemicals

- Preparation of 0.25 N potassium dichromate solution: –

12.25 gm. potassium dichromate powder dissolved in 1000 ml distilled water in 1000

ml volumetric flask. - Preparation of Ammonium Ferrous Sulphate solution: –

24.5 gm. Ammonium Ferrous sulphate powder dissolved in 250 ml distilled water in

250 ml distilled water in 250 ml volumetric flask. Add 5ml Sulphuric acid. - Preparation of Potassium Hydrogen Phosphate solution: –

0.425 gm. of dried KHP powder dissolved in 1000 ml distilled water in 1000 ml

volumetric flask. (Dried this powder for 2 hours in oven)

Procedure

- Took 0.4 gm. AgSo4 (silver sulphate) in COD tubes.

- Added 20 ml sample in each COD tube.

- Added 20 ml distilled water in each COD tube.

- Added stones (crush on beads) 1 or 2 pieces.

- Added 10 ml (0.25 N) K2Cr2O7 Potassium dichromate solution.

- Added 30 ml conc sulfuric acid slowly along with swirling.

- If the solution turns green more known quantities of K2Cr2O7 solution is needed to add.

- Kept COD tubes in COD apparatus to digest the sample..

- Attached the condenser & set 150 Degree Celsius temperature.

- Kept for 2 hours filled COD tubes in COD apparatus for 150 degree Celsius.

- After 2 hours switched it off & removed COD tubes & cooled sample for room temperature.

- Took the above sample in a conical flask. Added 150 ml distilled water.

- Titration: – Titrated above solution with 0.1 N FAS (ferrous ammonium sulphate) solution by using Ferron indicator (add 3-4 drops). The end point of this titration is blue green to reddish brown.

Formula of COD

COD = {(a-b) X N X 8000}/ml of sample solution

Where,

- A-Reading blank solution.

- B-Reading with sample solutions

- N- Normality of FAS solution

Dilution factor = ( ml of sample + distilled water )/ ml of sample

| Sample | Readings | COD (mg/lit) |

| Blank | 9.2 | – |

| KHP (experimental silver sulfate) | 4.7 | 470 |

| KHP ( standard Silver sufate) | 4.3 | 499.8 |

CONCLUSION :

In this experiment, 7.5 grams of silver sulfate was produced from 5 grams of silver.

When compared to the market price of standard silver sulfate, a quarter less amount is required for the synthesis of silver sulfate from silver.

Now we try to work on recovery of silver sulfate in COD .

Recovery of Silver from waste silver chloride

Hydrogen Peroxide Method

Hydrogen peroxide is a reducing agent in alkaline solutions. It reduces silver chloride into metallic silver. The reaction is shown as follows:

2AgCl + 2NaOH + H2O2—————> 2Ag + 2NaCl + 2H2O + O2

The advantages of this method are: 1. chemicals are inexpensive, 2. no exotic waste will be generated except sodium chloride, waste generation should be very small if low stoichiometry of NaOH is used. Despite its advantages, there is no quantitative information available in the literature. Therefore a lab-scale experiment was initiated to study this process.

The advantages of this method are:

1. chemicals are inexpensive,

2. no exotic waste will be generated except sodium chloride, waste generation should be very small if low stoichiometry of NaOH is used. Despite its advantages, there is no quantitative information available in the literature. Therefore a lab-scale experiment was initiated to study this process.

- Chemical Reactions Silver chloride is reduced to metallic silver in alkaline solution by hydrogen peroxide. Silver is then separated from the solution, dissolved in nitric acid, and converted into silver nitrate.

- Reaction 1 2AgCl + 2NaOH + H202………….

- Reaction 2 4Ag + 6HNO3 ————-> 4AgNO3 + NO + NO2 + 3H2O

Conclusions

- An efficient process has been developed in the lab-scale to convert silver chloride into silver nitrate. The conversion efficiency is better than 90%.

- The process is non-toxic, low temperature, and does not involve the use of hazardous reagents.

- The process is economical. The reagents required are sodium hydroxide and hydrogen peroxide which are inexpensive.

After Titration residue remaining in COD Samples Contains Silver Sulfate We recover it

- Added 20 ml of Liquor Ammonia to adjust pH of COD sample ( 5 sample)

- Then Added Excess amount of Hydrochloric acid 10 ml

- Silver Chloride Precipitated due its low solubility.

- then repeat the recover process of Silver sulfate using Hydrogen peroxide mention above.

Conclusion :

Cost for Checking a sample is approx.. 110 Rs. we can recover that about 65% using above method that means we have to spend only 70 to 75 Rupees per sample.