NEED OF PROJECT:

- Waste management has been always a challenge for us due to increasing population and less land availability for dumping ground.

- Biodegradable waste/kitchen waste can be converted into useful manure/compost. In compost, bacteria plays a very important. They breakdown organic matter thus fastens the decomposition rate of kitchen waste.

- By making use of this compost, soil is enriched which results in good growth of plants.

- Liquid compost bacterial broth if added to the kitchen waste, decomposition is fasten of the same and we can get good quality manure.

- For making such broth, ‘peptone’ is required in large quantity which is costly and thus the production cost of broth is increased. If this peptone is replaced by appropriate substitute, the production cost of liquid compost bacterial broth can be reduced and its use can be proved economical.

OBJECTIVE:

- To minimize the production cost of liquid compost bacterial broth.

- To increase the bacterial count of degradable waste and convert into manure.

PEPTONE PRODUCTION

Peptone is one of the compositions in Compost Bacterial Broth. Peptone can be extracted for its natural source i.e. soyabean. Following steps were carried out for extraction of peptone from soyabean.

- Soyabean chunk was grinded in a grinder.

- 40 gm of soya powder was added in 200ml of autoclaved water. Heat and constant stirring were provided to this mixture for 2 hours to form a slurry.

- The slurry was allowed to cool down and ph of the slurry was examined and was noted 6.

- HCL was added to it till the ph drops to 3 for hydrolysis of peptone.

- Further, Autoclaved water was added to the slurry in ratio 1:1 aseptically.

- Remaining components required for broth such as sodium chloride and yeast extract was added, 3.5 gm and 1.05 gm respectively to the slurry.

- After proper mixing of a remaining component using magnetic stirrer, Compost bacterial culture was inoculated aseptically and flasks were kept on a shaker for 72 hours 160 rpm.

Growth of required organism was observed in the broth after 72 hours.

Soya Chunk

Grinded Soya Chunk

Media

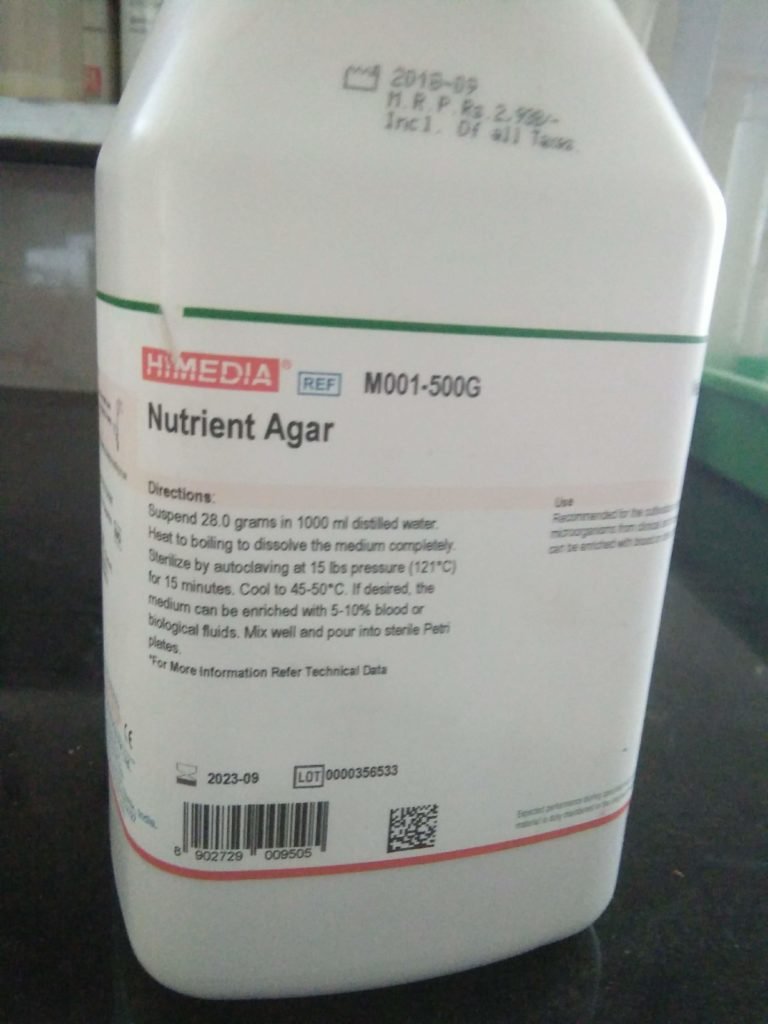

Nutrient Agar Media Preparation For Plating

Nutrient Agar media was prepared for Plating. N.A. media consist of following composition corresponding to 1000ml:

| Composition | Grams/Liter |

| Peptone | 5 |

| HM Peptone | 1.5 |

| Yeast Extract | 1.5 |

| Sodium Chloride | 5 |

| Agar | 15 |

All nutrients according to composition table above, except agar was added to autoclaved water in order to make media of 300 ml (addition of composition was done according to the following table) and the solution was heated for uniform mixing and was again autoclaved. Then this media was poured into the sterile petri dish aseptically and was allowed to cool.

| Composition | Grams/300ml |

| Peptone | 1.5 |

| HM Peptone | 0.45 |

| Yeast Extract | 0.45 |

| Sodium Chloride | 1.5 |

Observation: In a petri dish, media was expected to solidify in order to carry out the spread plate technique. But on the cooling of media, it was observed that solidification of media didn’t take place.

On Examination: It was understood that during the media preparation procedure, agar was not added; due to which solidification of media didn’t occur. Agar forms a solid medium for the growth of microbial colonies.

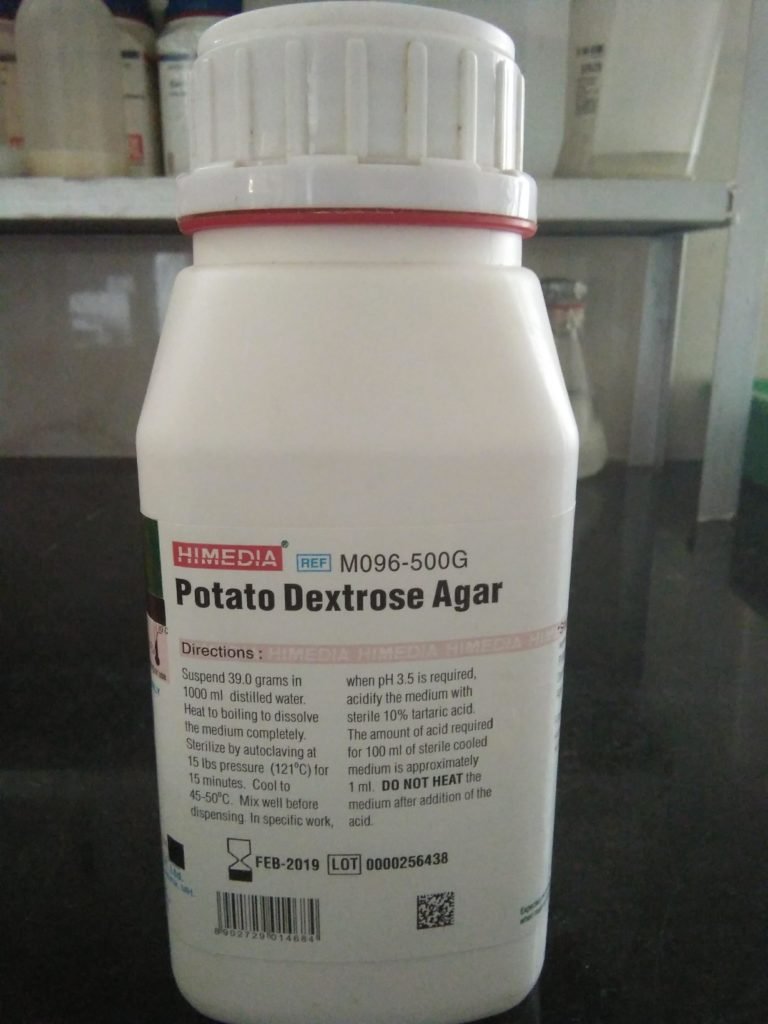

PDA (potato dextrose agar) Preparation for plating:

It was decided to carry out a spread plate technique to determine whether the bacterial growth has occurred or not in the modified broth. Following procedure was carried out:

- According to the standard value (i.e. 39 grams for 1000 ml), 11.7 grams of PDA was added to 300 ml of distilled water.

- The mixture was stirred well using electromagnetic stirrer and was autoclaved.

- After the broth was autoclaved, at a warm temperature (avoiding complete cooling ) the broth is poured aseptically into a sterile petri dish. And the petri dish was left undisturbed and media was allowed to solidify.

- Once the PDA plates were ready, 100 microlitres of test broth and control broth were inoculated aseptically on separate PDA Petri plate and spread it with sterile spreader throughout the agar surface.

- The inoculated Petri plate was incubated in the incubator for 72 hrs at 36-degree Celsius (but growth was observed every 24 hrs).

Laminar Flow

Incubator

Observation:

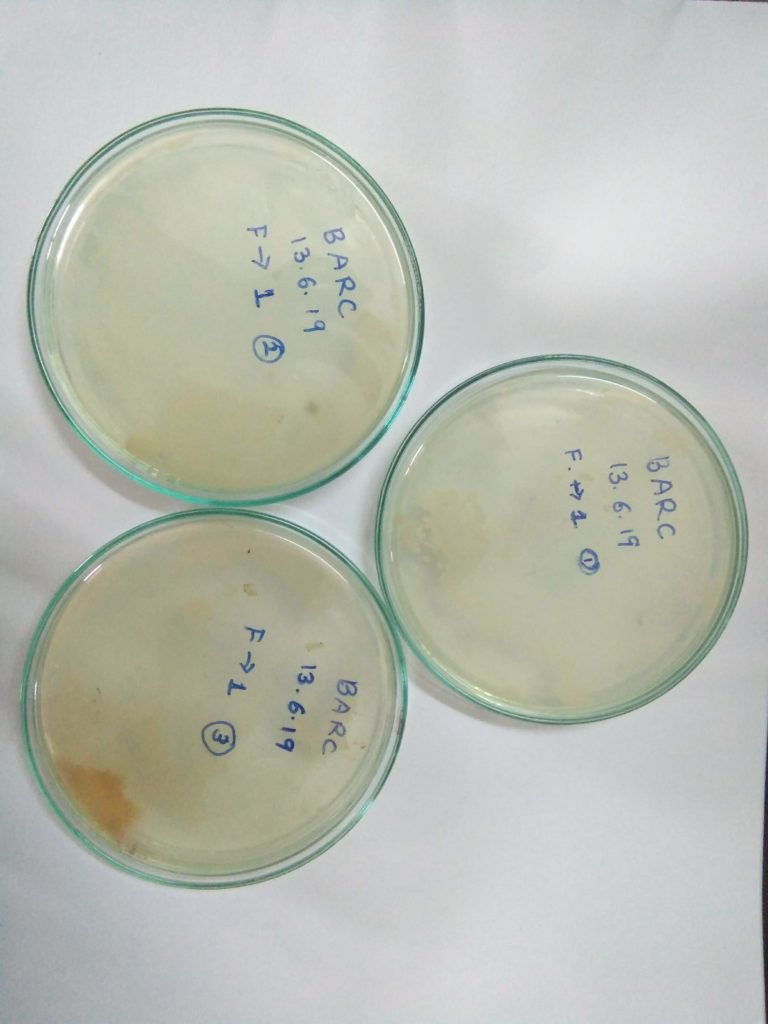

3 Petri plates each flask i.e. for flask 1, flask 2, flask 3 and control flask respectively; were inoculated and incubated for 72 hrs. Results observed were as follows:

- All 12 Petri plates showed positive growth.

- 3rd Petri plate of flask 2 and all 3 Petri plates of flask 3 showed growth of fungi i.e. here contamination has occurred.

Result:

- Control broth was made and by conventional methods. All the test flask (flask 1, flask 2, flask 3) had modified broth. The Petri plates inoculated from control broth and all the Petri plates inoculated from test broth showed uniform growth of bacteria. This means that the modified broth was able to multiply the Compost Bacterial culture efficiently as control broth. In other words, it contained all the nutrients in sufficient amount required for broth multiplication.

- 3rd Petri plate of flask 2 and all Petri plates of the flask 3 showed growth of fungi along with bacterial growth. This happened because of contamination had occurred.

Work Required on Following :

- When Slurry was made by adding soyabean chunk powder, it became very difficult to mix other broth composition uniformly as slurry was very thick.

- During plating, the particles of the slurry were blocking the micropipette and were becoming very difficult to pipette out exactly 100 microliters sample for spread plate technique.

- Also, these unwanted slurry particles were getting spread on PDA agar plate which was making difficult to take the bacterial count.

On review of Project work following points were noticed:

- The above procedure used for hydrolysis was not efficient.

- From soyabean we don’t get actual peptone. But soyabean can be a substitute for peptone in nutrient broth (with reference to research paper).

- When plating was done by the above method, only one kind of bacteria was observed. But compost contains more than 15 different bacteria’s and fungi also. So there was a need to make a new compost bacterial consortium.

- As the process of hydrolysis used above was not acceptable, another method was adopted for Compost bacterial broth modification as follows:

Replaced Method of Compost Broth Modification

CONSORTIUM:

A microbial consortium is two or more microbial groups living symbiotically.

Compost Microbial Consortium:

- Compost samples were taken from 4 different places. All samples were mixed together uniformly.

- 1 gm of it was taken out the mixture and add to 9 ml of autoclaved distilled water aseptically in order to make suspension for plating.

- 0.2 ml of suspension was inoculated on PDA plates; plates were incubated at 36 degrees Celsius for 8 days. These plates were labeled as master plates.

- On the 9th day, 300ml Nutrient Broth was made; all the bacterial and fungal growth on the master plate was scraped out with the help of a wire loop and inoculated into the sterile N.B. broth aseptically.

- The broth was placed on a shaker for 3 days at 130 rpm.

- After 3 days consortium was ready to use for broth trials.

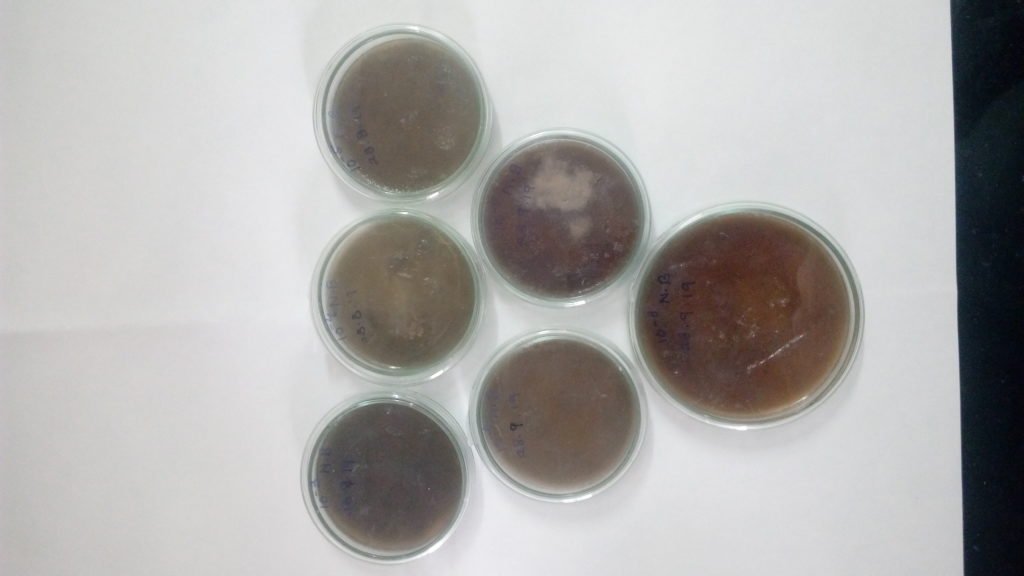

Consortium

Suspension

Master plate

Trial 1:

Trial 1 was undertaken to examine :

- Can Soyabean chunk prove to be a substitute for peptone?

- Does Soya support Bacterial growth as Peptone?

- Comparison of Compost bacterial growth on N.A., PDA, and Soya agar plate.

SOYA AGAR PLATE:

- 50gm of Soya chunk powder was weighed and soaked in 100ml of distilled water for 30 min.

- After 30 minutes of soaking, it was minced for 30 seconds and then boiled for 10 minutes.

- After boiling, the cooker was allowed to cool and then the extract/ filtrate of cooked soya was taken into a conical flask.

- Distilled water was added to the filtrate to make its volume upto 500ml.

- 3 gm of agar agar powder , 0.3 gm of yeast extract, 1 gm of sodium chloride was added to the filtrate.

- Autoclave the media. After autoclaving media pour media into sterile petri plate asceptically and allow the media to get solidify. After solidification plates are ready to use.

PDA PLATE:

- 7.8 grams of PDA weighed and added into conical flask.

- 500ml of distilled water was added and mixed it properly with use of magnetic stirrer.

- Autoclave media

- After autoclaving pour media into sterile petri pate asceptically. Allow the media to get solidify. Plates are ready to use.

NUTRIENT AGAR PLATE:

- 1.3 gm of peptone, 0.3 gm of yeast extract, 1 gm of sodium chloride and 3gm of agar agar powder was weighed and added to 500ml distilled water in a conical flask.

- Mix all above properly with help of magnetic stirrer.

- Autoclave media .

- Pour the media into sterile petri plate aseptically and allow the media to get solidify.

- After solidification of media, plates are ready to use.

Streaking of consortium on PDA, N.A and SOYA agar plate( to check which media supports maximally for Compost bacterial growth):

- 1 ml of consortium was added to 9 ml of autoclaved distilled water in a test tube aseptically in order to make suspension.

- Loop full of culture/suspension was streaked on PDA, N.A. and SOYA agar plate (each 5 plates)

- The plates were incubated for 7 days at 36 degree Celsius.

OBSERVATION:

Compost bacterial growth was observed on all 3 types of plates.

RESULT:

SOYA agar plate supports the Compost bacterial growth in same manner like as PDA and N.A. plates.

CONCLUSION:

Hence, from observation it was known that soya can be a good substitute for peptone in Nutrient broth. By use soya in making liquid media we can reduce the production cost of broth remarkably.

Trial 2:

Trial 2 was undertaken to examine:

Comparison of Compost bacterial growth in 3 different kinds of liquid media broth: 1)Nutrient Broth 2)Urea & Jaggery 3)SOYA

LIQUID BROTH MAKING:

A) NUTRIENT BROTH (Control):

- 4 liters of water was boiled.

- After cooling of water, 26 gm of peptone, 6 gm of yeast extract , 20 gm sodium chloride was weighed and added to the water in a Can.

- It was made sure that all the above composition are mixed properly.

- 200 ml of consortium was added to the media and the Can was kept on shaker for 48 hrs at 160 rpm.

B) UREA & JAGGERY BROTH (Test broth 1):

- 4 liters of water was boiled.

- After cooling of water, 80gm of jaggery and 40gm of urea was weighed and added to the water in a Can.

- After mixing of urea and jaggery properly in water; 200ml of consortium was added to the broth and kept on shaker for 48 hours at 160 rpm.

C) SOYA BROTH (Test broth 2):

- 400 gm of soya chunk powder was weighed and soaked in 800ml of distilled water for 30 mins.

- After 30 mins, the soaked soya chunk powder was minced for 30 sec and the cooked in a cooker at low flame for 1 hour.

- After the cooker is cooled, the filtrate is taken of it in a Can.

- Water was boiled and cooled down. This water was added to the Can to make volume upto 4 liters.

- 6 gm gm of yeast extract, 20 gm of sodium chloride was added was added to the broth and mixed properly.

- 200 ml of consortium was added to broth, mixed well and then the Can was kept on shaker for 48 hours at 160 rpm.

SERIAL DILUTIONS:

- After 48 hrs of inoculation, the samples was derived from 3 different broths.

- Plating of these samples was done separately by using serial dilution and spreadplate technique on PDA plates in order to get bacterial count in each kind of broth.

- The plates were incubates at 36 degree Celsius for 4 to 5 days.

OBSERVATIONS:

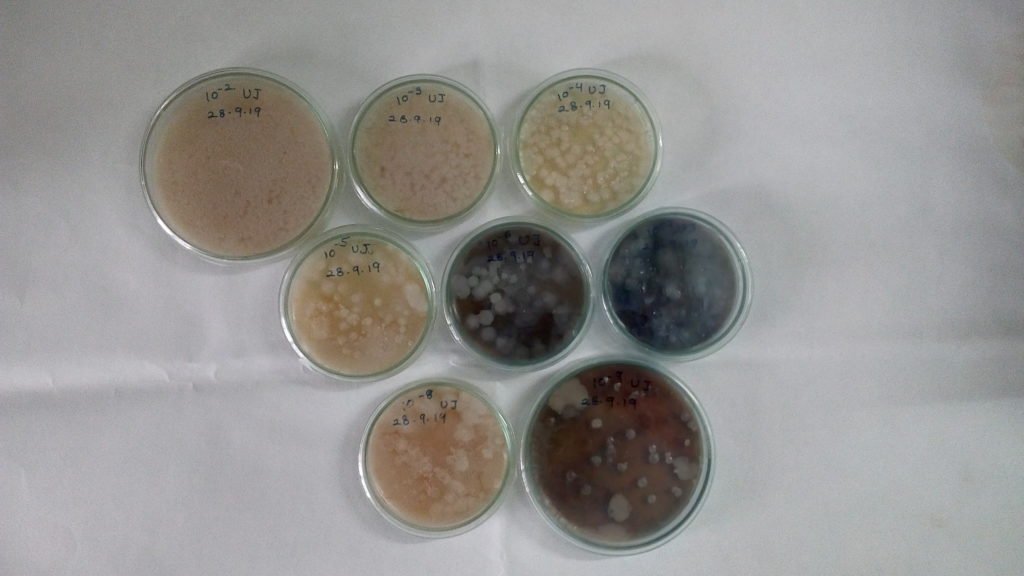

- All the plates of 3 different kinds of broth showed a lot of bacterial growth.

- The bacterial growth was such that it became difficult to take bacterial count.

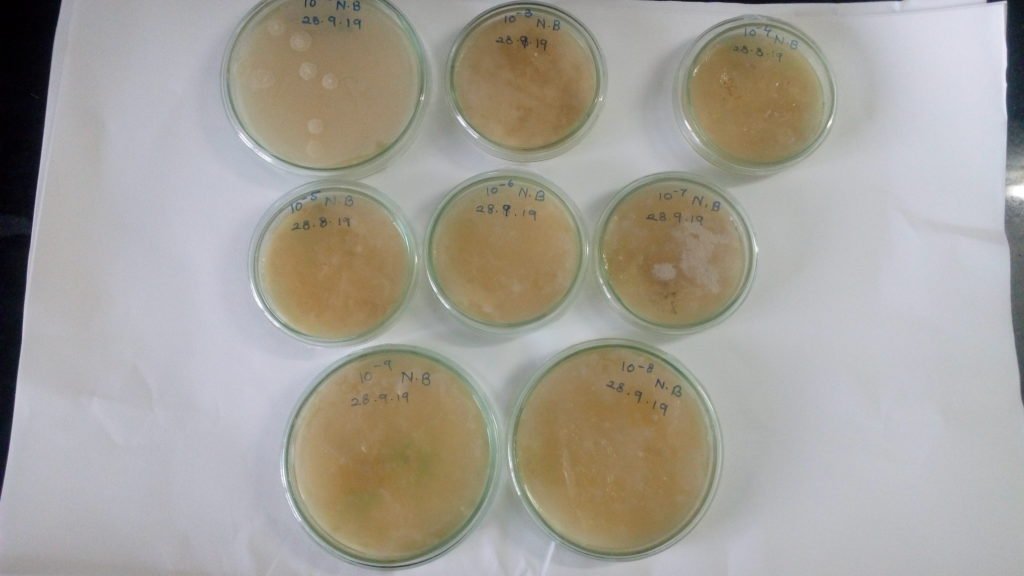

Nutrient broth

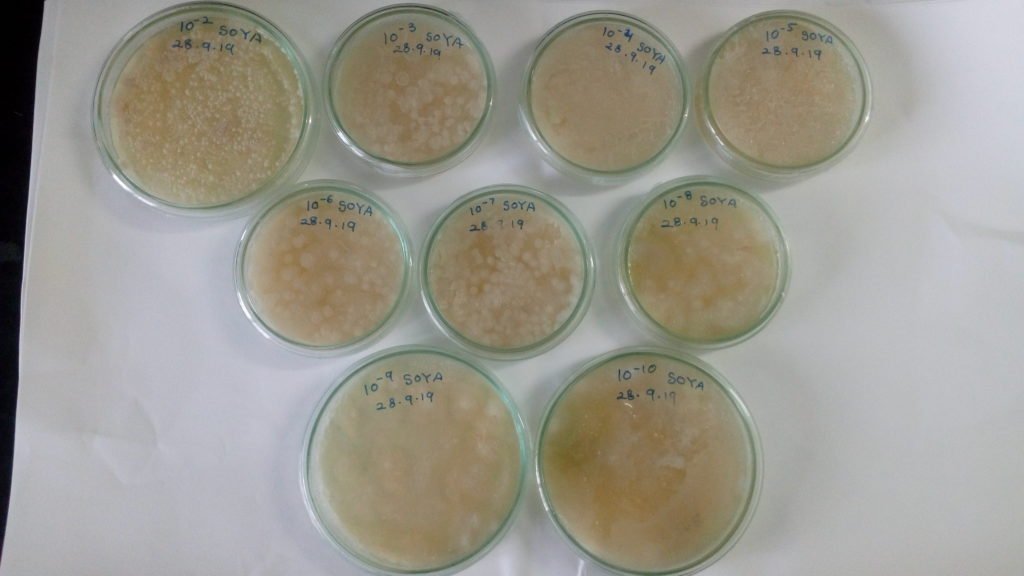

Soya broth

Urea & jaggery

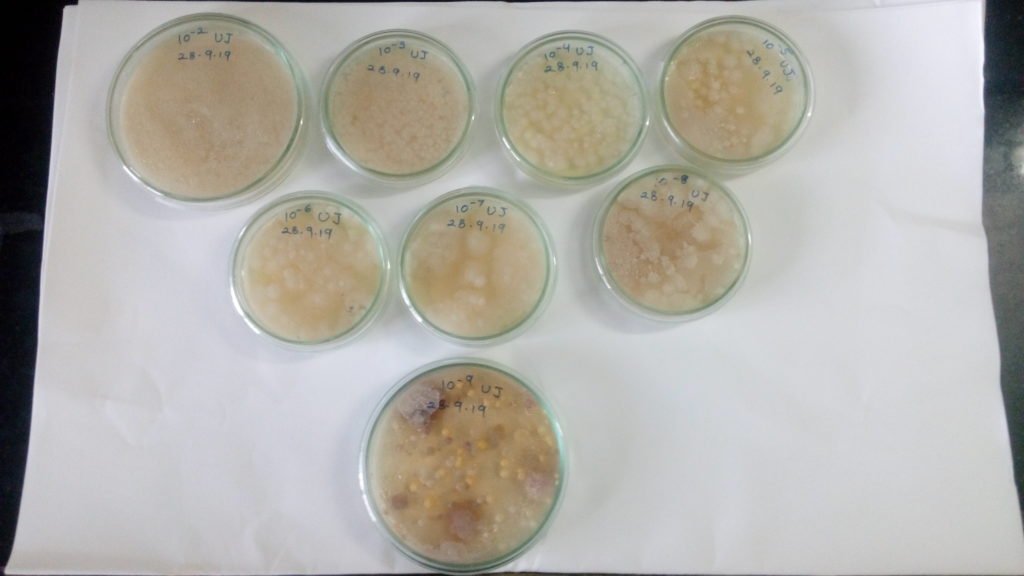

Plates after 1 week incubation:

Nutrient Broth

Urea & Jaggery

Soya broth

Trial 3:

From trail 1 and 2 following doubts/points were raised:

- How much Compost bacterial growth does Soya Chunk alone support(i.e. without using sodium chloride and yeast extract in broth)?

- Which Broth proves to be best broth in both ways, economically and biologically? (Urea & Jaggery or Soya broth).

In order to Examine above aspects, trial 3 was conducted as follows:

A) Control:

- 200 ml of distilled water was taken in a conical flask and autoclaved.

- After cooling 10 ml of mother culture(consortium) was added to it aseptically.

- The flask was kept on shaker for 3 Days at 160 rpm.

B) Soya:

- 20 gm of soya chunk powder was weighed and soaked in 40ml of distilled water.

- After 30 mins, it was minced for 30 sec and cooked in a cooker for 1 hr on a low flame.

- After the cooker is cooled down, filtrate was taken of the cooked soya chunk powder in a conical flask.

- Distilled water was added to the conical flask to make volume upto 200ml.

- Media was autoclaved.

- After cooling of media, 10ml of mother culture was inoculated aseptically.

- The inoculated media, the flask was placed on shaker for 3 days at 160 rpm.

C) Urea & Jaggery:

- 4 gm of jaggery and 2 gm of urea was weighed and added to conical flask.

- Distilled water was added to make up volume upto 200 ml.

- Media was autoclaved.

- After cooling of media ,10ml of mother culture was inoculated to the media aseptically.

- The flask was kept in shaker for 3 days at 160 rpm.

Inoculation of Broth

Broth Before Inoculation

AFTER 3 DAYS OF INCUBATION:

- Samples from above 3 different broth was derived.

- Suspension was made of respective sample in order to perform serial dilution on PDA Plates.

- The plates were incubated at 36 degree Celsius for 48hrs.

- After 48 hrs plates were observed and bacterial count was noted down with the help of ‘Colony Counter’.

Colony Counter

Counting Colonies

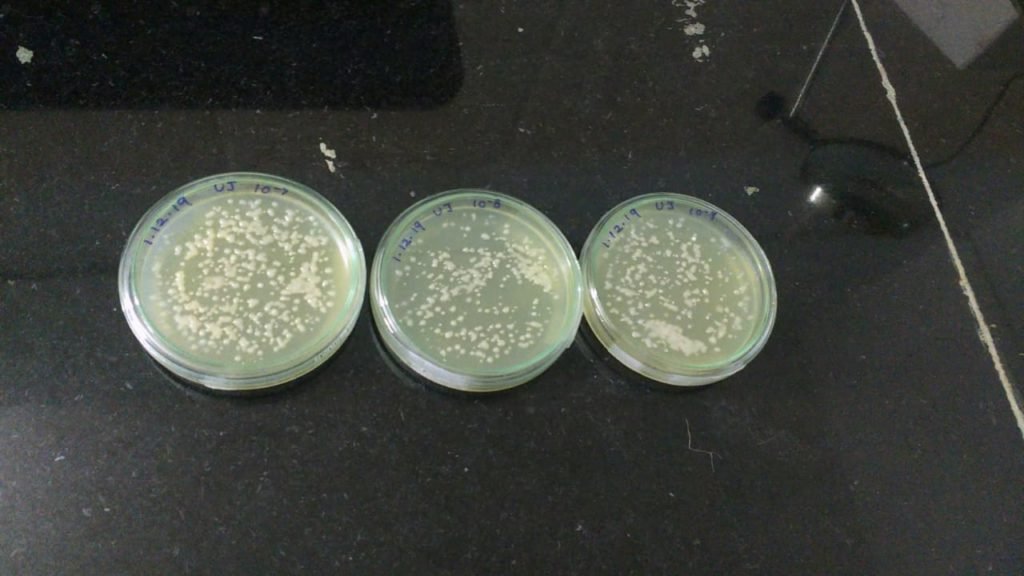

Incubated Plates

Observations:

Distilled Water(control)

Plates

SOYA

Plates

Urea & Jaggery

Plates

While taking the bacterial count; 10-7 ,10-8 ,10-9 serial dilution plates were considered. Following is the Observation table of the Bacterial Count of the Control, Soya and Urea & Jaggery Broth:

| Broth Type | Count 10-7 | Count 10-8 | Count 10-9 |

| Distilled Water (Control) | 755*107 | 700*108 | 540*109 |

| SOYA Broth | 1595*107 | 1080*108 | 610*109 |

| Urea & Jaggery Broth | 1100*107 | 915*108 | 605*109 |

Conclusion:

According to the above Observation Table; we can see that the bacterial count of the ‘SOYA Broth’ is more as compared to the ‘Urea & Jaggery Broth’. Hence Soya supports the growth of ‘Compost Bacteria’ more as compared to Urea & Jaggery. In other words ‘SOYA broth’ proves to be a good broth in comparison to ‘Urea & Jaggery broth’ for multiplication of Compost Bacteria.

Costing Of Broth:

Though we have modified or produced a broth for multiplication of Compost Bacteria; when it comes to “Production and Marketing of the Product”, Costing of the product matters a lot. Hence, further step in this project was taken towards making a costing chart of the Broths. Following are the Costing charts for :

- Regular Nutrient Broth( Before Modification)

- SOYA Broth

- Urea & Jaggery Broth

Regular Nutrient Broth:

| Composition | g/Lit | Cost |

| Peptone | 6.50 g | 43.095/- |

| Yeast Extract | 1.50 g | 3.624/- |

| Sodium Chloride | 5 g | 2.1/- |

| Total Cost: | 48.819/- |

Soya Broth:

| Composition | g/Lit | Cost |

| Soya | 100 g | 8/- |

| Yeast Extract | 1.50 g | 3.62/- |

| Sodium Chloride | 5 g | 2.1/- |

| Total Cost: | 13.72/- |

Urea & Jaggery Broth:

| Composition | g/Lit | Cost |

| Urea | 10 g | 0.1 /- |

| Jaggery | 20 g | 0.88 /- |

| Yeast Extract | 1.50 g | 3.62 /- |

| Sodium Chloride | 5 g | 2.1 /- |

| Total Cost: | 6.62 /- |

Calculations to Compare between ‘Soya’ and ‘Urea & Jaggery’ Broth based on Production cost and CFU:

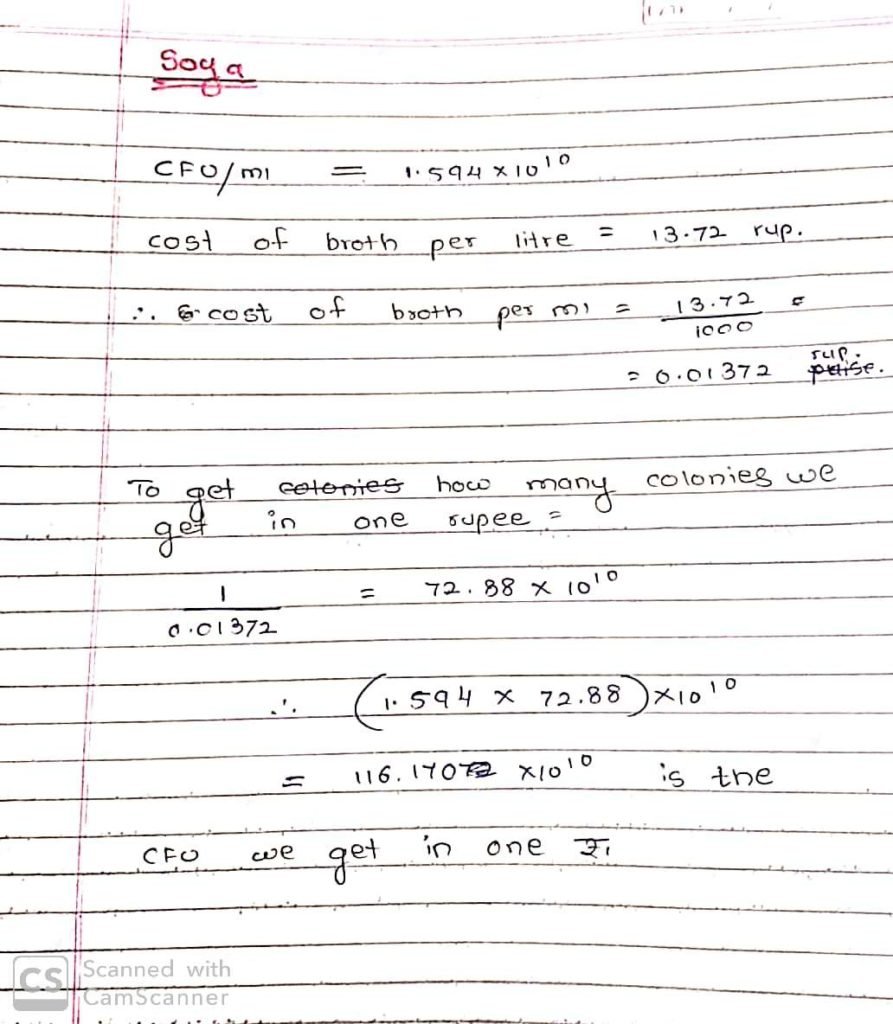

Soya Broth:

- CFU/ml = 1.594*10^10

- Cost of Broth per Litre = 13.72 rup

- Therefore the cost of Broth per ml = 13.72/1000 = 0.01372

- To get the number of colonies we get in 1 rup- 1/0.01372 = 72.88*10^10 therefore, (1.594*72.88)*10^10 = 116.170*10^10 is the CFU we get in 1 rup from Soya Broth.

Urea & Jaggery Broth:

- CFU/ml = 1.100*10^10

- Cost of Broth per Litre = 6.624 rup

- Therefore the cost of Broth per ml = 6.624/1000 = 0.006624

- To get the number of colonies we get in 1 rup- 1/0.006624 = 151.51*10^10 therefore, (1.100*151.51)*10^10 = 166.661*10^10 is the CFU we get in 1 rup from Urea & Jaggery Broth.

Project Conclusion:

- Technically Soya Broth is effective and supports more for the Multiplication of Compost Bacteria as compared Regular Nutrient Broth and Urea & Jaggery Broth.

- But when it comes to production Cost of the Broth , Urea & Jaggery broth is economical compared to Soya Broth and Regular Nutrient Broth.

- We get about 116.170*10^10 Bacterial Colonies in 1 rupee from Soya Broth.

- We get about 166.661*10^10 Bacterial Colonies in 1 rupee from Urea & Jaggery Broth.