My first assignment was to design a portable charcoal stove for Samuchit Envirotech, a Pune based company which specializes in designing and manufacturing affordable and sustainable products for rural and sub urban population.

The challenge was to design a stove compatible with an existing cooker which would be used at home and also during travel to far off destinations, e.g.- Many people from Maharashtra make journey to Pandharpur a holy place from their native on foot. Thus the stove needed to be as compact and foldable as possible.

Week 12(August 25-September 2)

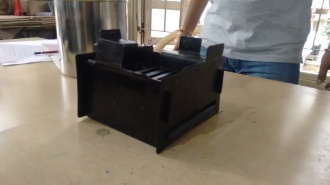

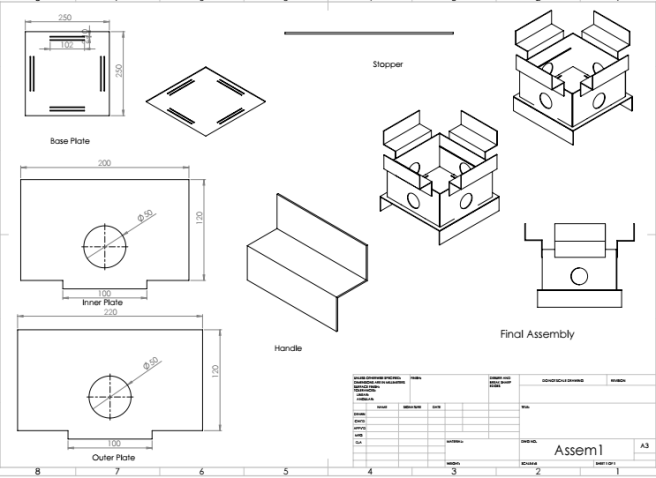

The final design is ready for production.The final design will be handmade and made in 2mm Mild Steel. This is the final product.

Week11(August18-August24)

The post processing on the steel was done at DIY lab Pune. Process such as bending, grinding, polishing and painting was done. Welding was done from a third party. I did not anticipate the damage done to the steel while it was worked on thus I need to do some damage control on the same. Our believed “KAKA” helped me a lot in this

After painting the stove I presented the same to the client. The client tested the design with their cooker for dimensions and fitting. They were happy with design, the purpose was served, the stove was portable, consumed less space and rigid. Now they will test the design for heating efficiency.

Although it was decided at the meeting that a 1mm steel can work well, this will reduce the weight of the stove(presently 1.8kg),cost of material and ease of working.

Week10( August11-August17)

Unfortunately the Plasma cutter installed at Vigyan Ashram did not work, it failed to cut the 2mm steel. I communicated the same to the client and asked for their permission to get it done from a third party.

I got the laser cutting done from Kakade Laser at Pune, although the final cutout were not precise but the quality of the print was good.

Week 9(August4-August10)

Although the design was approved by the client there are some minor dimension changes in the design, those will be incorporated and a final prototype in MDF will be made.

The following design was approved by the Client and we will be going ahead with final prototype in steel. This will be made using the newly installed plasma cutter.

week 8&9 (July 20- August 3)

I took a different approach to the problem and devised a following design

This design has welding only to a for a smaller portion.The stove is easy to assemble and dismantle. On dismantling it consumes very little space. The follow is a prototype of the stove made in MDF sheet.

Following are the salient features of the design

1 The stove is very portable, after dismantling the size of the stove becomes 120mm*150mm*35mm.

2 It does not hav any nut and bolt or hinge only a welding for 50 mm length, thus the stove is as good as the grade of steel it is made from

3 Easy to put assemble and dismantle

4 Provides enough space to hold the fuel and also enough space for circulation of air to burn it.

Week 6&7(July 6-July 19)

After this I had a detailed meeting with the client, the client gave their inputs which were immensely important.

It was observed that the assembly was wobbly and lacked strength also the assembly did not act as a single unit when assembled.

Week 4 & 5(june 23- july 5)

I proposed the following design

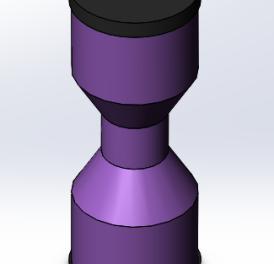

After testing the various ideas I did my final assembly in Solidworks. I cut pieces MS according to the design and tried how well the design works.

Week 2& 3( june 9- june 22)

The approach

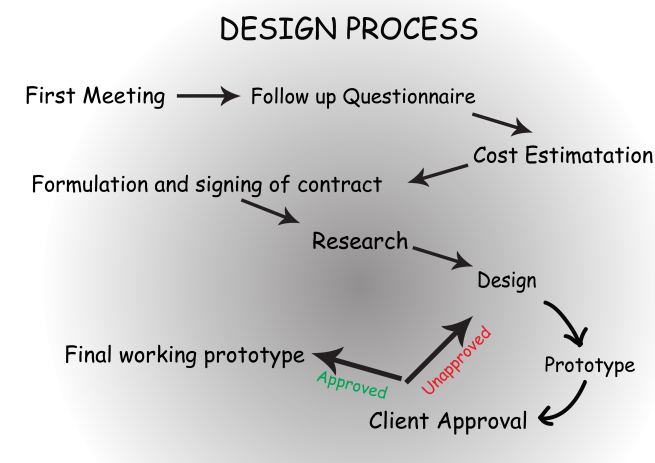

1 I had a detailed meeting with the client and understood the requirements, drafted a questionnaire and got the answer for the same. Got the client involved in the process of designing.

2 Did a literature review on the internet and studied similar products in the market.

3 Tested my ideas with cardboard before moving to metal works. I ensured that the design was in line with the manufacturing capabilities at the workshop.

Week 1 (June 2-June 8)

My first assignment as a student of DIC is designing a portable stove.I am trying my hands on commercial project for the first time hence this project is a testing ground for me and my mentors

Samuchit Envirotech is a company based in Pune which specialises in providing solutions to mundane problem of lower and middle lower class people.

The design problem was follows,

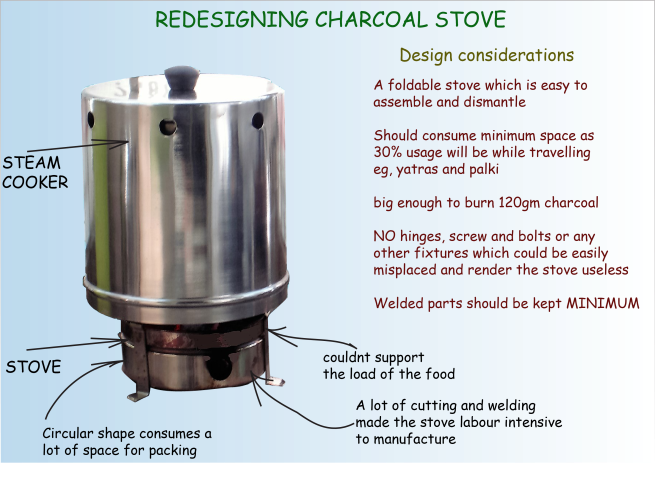

The client had to redesign the stove meant for the cooker as shown in the picture

The steam cooker used charcoal fuel to generate steam and cook the content inside.The existing stove was circular shaped and required separate box for packing. The client wanted me to design a stove which will consume very less space and would fit into the same box in which the cooker is packed.

Features required

1 The target customer is a a lower income group population dwelling in flats and temporary structures, these people do a lot of travelling during “yatras” and carry their cooking material with them. Hence the stove should be easy to dismantle and carry along, it should be as sleek as possible.

2 After studying physically a few portable stove we shortlisted a few things the stove shouldn’t have

a) any small fixtures which can easily get misplaced during transport and render the stove useless thus use of nut and bolt as fixtures was out of options

b) a few of the products used hinges to facilitate folding of the stove, but the hinges didn’t perform well after exposing to the heat similarly results were observed in the nut and bolt arrangement, thus use of hinge was also not anticipated

c) The stove should have no or minimum welded parts.

After understanding the requirement of the client, I discussed at length with Subir Sir and formulated a contract. A cost estimate was sent to the client which was agreed upon and signed.